The Nismo Heritage Program Will Start 3D Printing Parts For The Skyline

Nissan is expanding its Nismo Heritage Parts program once again and the list of what's available just keeps growing. Nissan announced it's adding new Skyline parts to its catalog with the help of robots and additive manufacturing, AKA 3-D printing.

The Nismo Heritage Parts program started in 2017, and in 2019 a process Nissan refers to as dual-sided dieless forming allowed the company to stamp sheet metal at a small scale.

Watch the process in the video below:

This production process lets Nissan form steel panels without traditional assembly lines which can be prohibitively expensive and is therefore uncommon for discontinued models. Due to the high cost of production, scale is where the money is so until recently, small reproduction runs were rare at best.

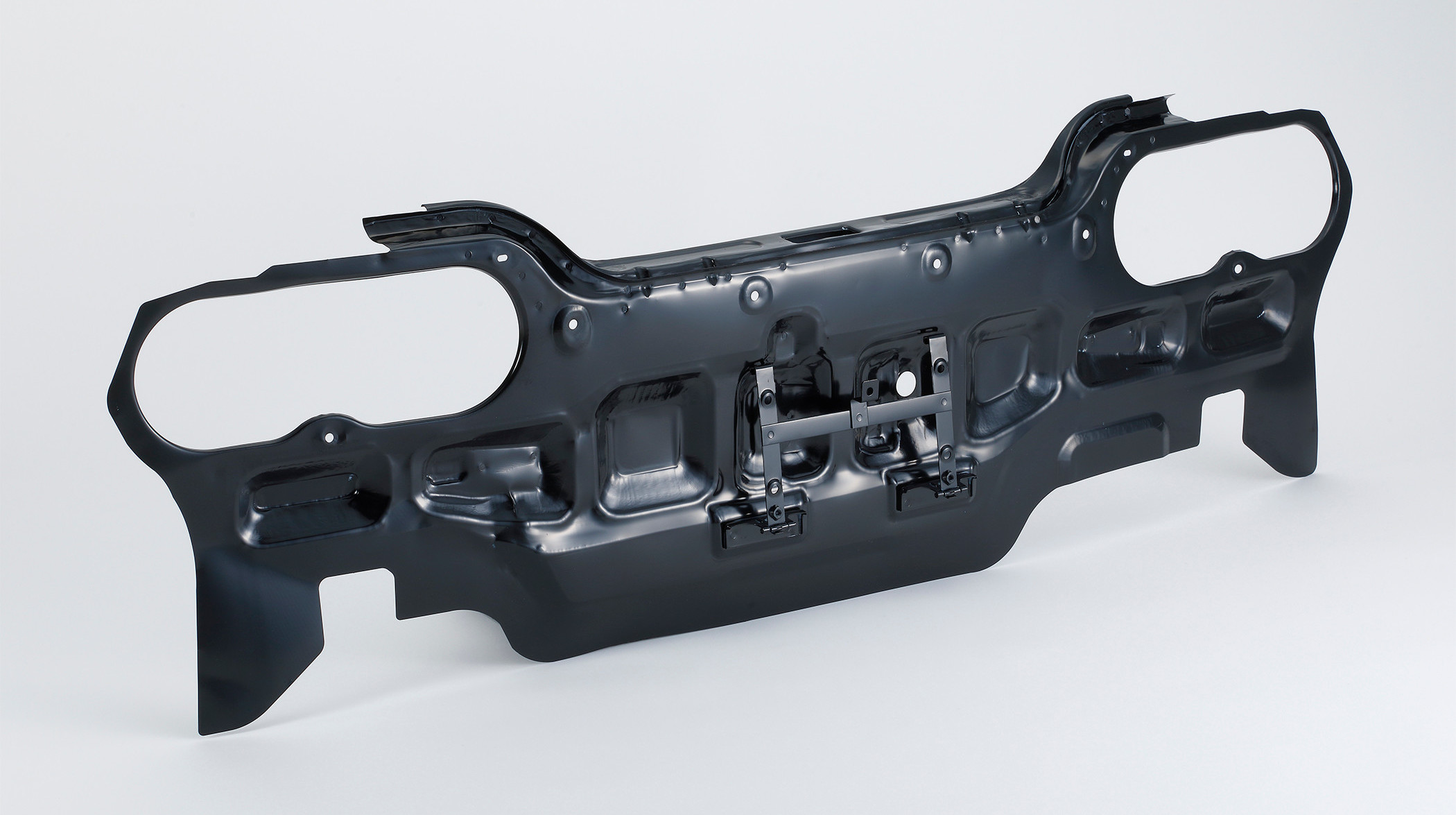

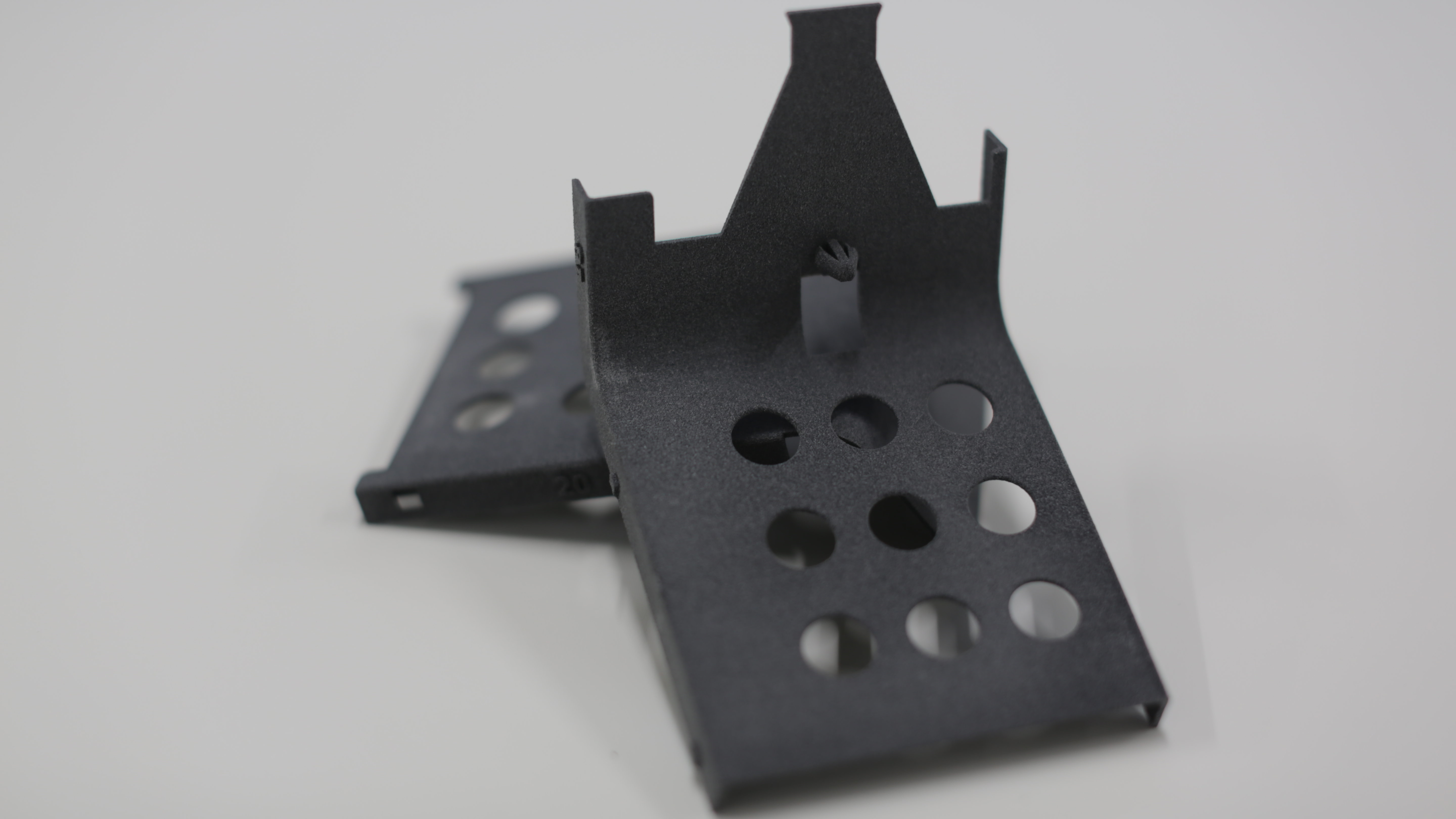

But these robots and the 3D printing boom have made old parts reproduction accessible. Nissan will make rear panels for the R32 generation Skyline with the robots and will be 3D printing harness protectors with industry partners.

Solize Corporation and HP Inc. partnered with Nissan to pick which parts can be successfully reproduced through additive manufacturing. Solize is an engineering and product development company and HP Inc. is well, of Hewlett-Packard tech fame. The two partner companies have stated the harness protector is the first part they've identified as a candidate for 3D printing. That makes it seem like there could be others on the way. We'll see.

Additive manufacturing has come a long way now from when we began to see it applied to the auto industry. Big carmakers such as Bugatti, Cadillac and Mini have used the tech to produce parts for both prototyping and production cars. The production process of 3D printing is now living up to its promise.

The Heritage Parts program boasts 300 parts now, from an initial catalog of 80. I love to see these kind of offerings from carmakers. The aftermarket usually steps in to keep cars around or to enhance them in myriad ways, but to see a carmaker invest in the long life of its cars always makes me happy.

Sure, it makes sense that these are parts for performance cars, for the famous Skyline GT-R in its R32-34 generations, but I daydream of reproduction parts for the rest of us and for our beat up dailies.

We make a big deal about right-to-repair, as we rightly should. There's also the right to restore or prolong. As production tech matures and is refined we may see more machines like Nissan's robots, and the viability of older cars as road-going machines increases.