Electric cars are heavy. This isn’t news to anybody, but it’s still something EV designers struggle with. The reason they’re so heavy is because batteries are heavy. For example, the batteries in a Tesla Model S account for nearly a quarter of the car’s entire weight. That’s a lot. Efforts to reduce battery weight by building batteries that are also part of the car’s structure are a promising concept, and a team of Swedish researchers seem to have made a big advance here, developing a structural battery system that uses a carbon-fiber anode.

Tesla has been developing structural battery packs as well, but the method they’re using still requires individual, cylindrical battery cells, held in place by a matrix that’s also providing structural support as part of the car’s frame.

Essentially, Tesla’s method is just embedding cylindrical battery cells in housings that are also part of the car’s frame. This is a good approach, but the Swedish team from Chalmers University of Technology (no relation to the Superintendent) led by professor Leif Asp (no relation to the snake) takes this concept a step further, making every component of the battery itself out of structural materials.

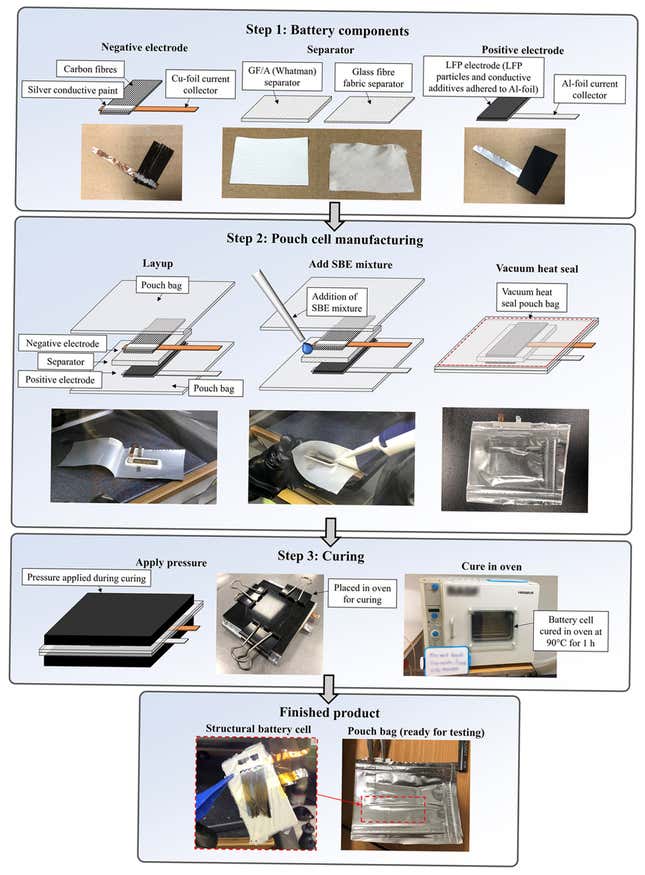

Here’s what they’re building:

...we propose a structural battery composite material made from multifunctional material constituents and demonstrate its multifunctional performance. The structural battery composite consists of a CF negative electrode and an aluminum film‐supported positive electrode separated by a GF separator in a SBE matrix material.

To dumb that down just a smidge, the negative terminal of the battery is made of carbon fiber, and the positive terminal is aluminum foil coated in lithium-iron phosphate, and there’s a fiberglass separator that’s in the battery’s structural electrolyte matrix.

Pretty much every part of this battery is capable of supporting structural loads, and not some lazy, freeloading cylindrical cell just snoozing away in some structural matrix that’s doing all the work.

The team developed structural battery cells that provided 2.8 volts, and calculated the energy density of the batteries at about 23.6 Wh per kilogram. While this is less than the 380 Wh per kilogram that the 4,680 cells that Tesla uses, you have to keep in mind that these batteries would require no extra structural frame weight, and so a car built with this sort of energy-storing frame would likely have an overall energy density much better than one using traditional battery cells.

The whole paper is here, if you’re interested. It seems very impressive.

The potential for making far lighter electric cars and even aircraft with structural batteries is very exciting and has some real promise, but it also comes with a very significant, I think, problem: the life of the vehicle is now completely tied to the battery.

While current electric cars generally do not make battery replacement easy or convenient or even affordable, it’s still possible, and that would be given up entirely if the whole structure of the car is the battery.

It’s a more efficient design, sure, and could really help with range and efficiency, but from a consumer standpoint, I’m not sure it’s the best way to go, since I still believe battery swapping is a better long-term approach.

My concerns about that aside, this is absolutely a significant development, and should lead to better EV designs of many kinds.