The 10 Worst Car Factories In History

This story was originally published on June 25, 2014

These are the car plants where competence, build quality and all your hopes and dreams went to die. Their cars should have come with a sticker that said "Made With Pride in You Don't Want To Know."

This story was originally published on June 25, 2014

10.) Kragujevac Zastava Factory

NATO took care of the Yugo problem once and for all in 1999. Still, while they used to build terrible cars, things have changed according to Aetost:

I get the feeling that the strike was ordered by some begrudged ex-Yugo owner, as a payback...

Still, they cleaned up the ruble and kept producing the Yugo, even during the war. Their tenacity paid off and eventually the plant (and the company) was bought by FIAT and is now renovated and considered among the company's best sites.

Suggested By: JayHova

9.) Detroit Chrysler

Imported from Jamaica.

Suggested By: jbh

8.) GM Norwood Assembly

Just blame the unions if your Camaro falls apart, says Stig-a-saw-us-wrecks:

The Camaro, Firebird, Nova, Impala, Bel Air, Biscayne were all assembled here at various times. Site of one of GM's longest labor dispute at 174 days. When it closed, the city of Norwood lost 28% of it's tax revenue.

Suggested By: Stig-a-saw-us-wrecks

7.) Alfa Romeo Pomigliano d’Arco

The reason why you can't find an Alfasud anywhere despite them building almost a million. tapzz:

Built as a brand new plant in a mafia-ridden area near Naples, southern Italy in the '70s to produce Alfa Romeo's Alfasud compact. The workforce had no experience of car building, or any desire to learn, given that there were 700 stoppages on the line when the 'sud was being built. Body shells of craptacular soviet steel were left outside to rust before they were even painted. The output was so bad in build quality Alfa still hasn't lived down the consequences, even though the 'sud was generally hailed as the best handling car of its day, and one of the best car designs of the '70s.

Certainly the best example of a car design as good as the factory was crap.

Suggested By:tapzz

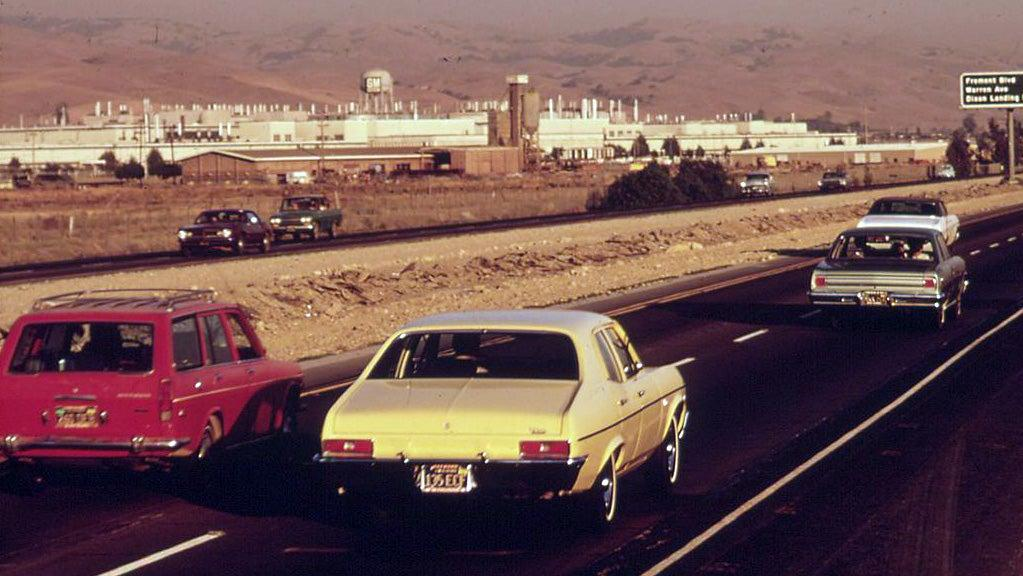

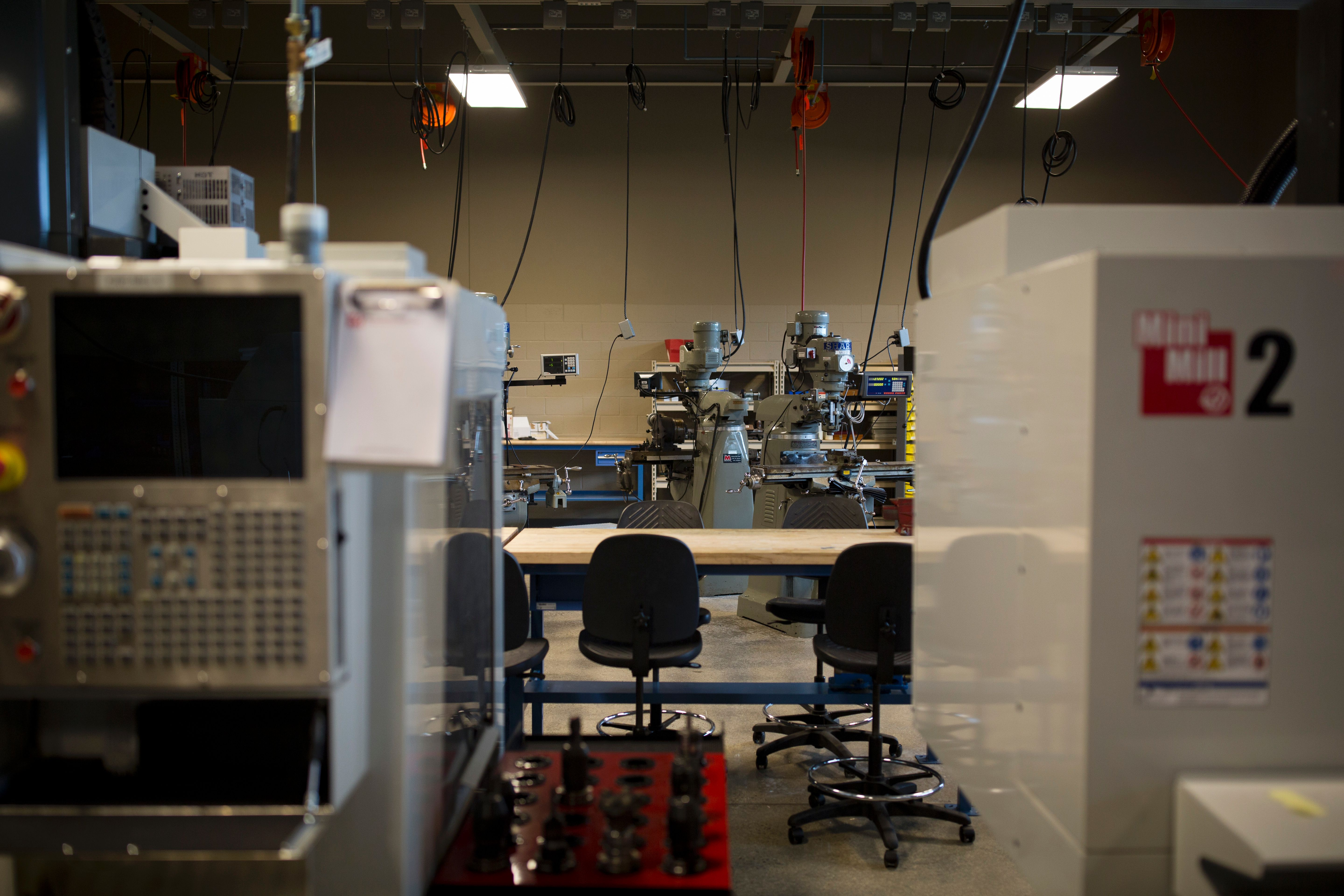

6.) GM Fremont

Well, you can write a book on this one. Loping Camshaft sums it up:

The GM Freemont-cum-NUMMI-cum-Tesla plant. It was an embarrassment to American manufacturing and called "the worst workforce in the automobile industry in the United States", according to the UAW. Think of the cars of the Malaise Era, then this all makes sense. Thankfully, the plant closed...

Only to be reopened by a joint venture between Toyota and GM. It was Toyota's first plant in the US and they wanted to see what it was like running a plant in the US versus Japan. They eventually got the QC up to par. GM wanted to learn some of the more efficient Japanese manufacturing policies and implement them at other factories. That didn't happen.

Mercifully, the Ponitac Vibe was killed and the plant was shut down in '09, only to be resurrected by our South African overlord, E-lon Musk.

Suggested By: Loping Camshaft

5.) VW Westmoreland

They were right. It wasn't a Golf. themanwithsauce:

From 1978 to 1987 it languished around as a facility that made the rabbit, rabbit GTI, and rabbit pickup along with some Jettas at the end of its time as a VW plant. However the rabbits they made in AMerica were nowhere near the quality of the German made Golf. The workers were assembled as a mix of those from the UAW plants in Detroit and a large pool of unemployed labor. VW picked the ones that had been out of work for the longest. BUT WAIT, THERE'S MORE! Because the VW plant was paying LESS than the Detroit plants but was also represented by the UAW, there was a strike for equal pay within the first few months of the plant opening. Walkouts were common and dispute over minorities plagued the plant for its entire life. In the words of the New York Times, the plant began life with a strike and then lurched from problem to problem before closing.

It gets better – stamping facilities were 4 hours away in Virginia. 4. Hours. Away. That is absolutely stupid. Parts were rushed via private jet sometimes to keep production going. And they would, because the plant needed to run at 85% capacity to break even. It was outdated when built and had poor quality labor in a plant that lacked automation in an era where robots and machinery were replacing the excessively large and unreliable labor force.

It is absolutely impressive that VW was brave enough to come back at all. Westmoreland was a textbook case of how to do everything wrong when you make a new auto plant.

Suggested By: natrat

4.) Zwickau

They fixed everything by kicking it as hard as they could until the part was roughly in line. Then, they tried to sell them to you.

SheikhБлять also heard rumors about a North Korean connection:

You have no idea how crazy the Zwickau factory actually was.

Toward the end, they flew out North Korean workers from Pyongyang once a week (one of Air Koryo's only flights to the West at the time) to work on the assembly line, hand cutting the Duraplast. It is a testament to their skill (and fear) that Trabant 1.1s exist and appear to be the most strangely polished models of Trabi.

Suggested By: Maxton86

3.) Rootes Group Linwood

Remember the Volvo P1800? Well, you want the S version because it was built in Sweden instead of Scotland, along with many of the Chrysler-Rootes Group cars. ranwhenparked has more:

The Chrysler-Rootes plant in Linwood, Scotland was pretty terrible. It was constructed specifically to build the Hillman Imp (full disclosure, I actually kind of like that car, my dad's British expatriate friend had one for decades).

Chrysler wanted to build the car at their existing factory in Ryton, but oh no no, the UK government had other ideas. With Scotland's shipbuilding industry essentially dead (partly, OK, heavily due to government policy), the idea was to replace it with car production. So, Chrysler was denied the necessary permits to expand the Ryton plant, but was given generous subsidies to build a new factory in Linwood and really needed to build the car somewhere, so they went with it.

All their suppliers were still located in England, Linwood was basically in the middle of a vast no-man's land for the auto industry, which led to high transportation costs and frequent parts shortages. The local workforce was inexperienced in car assembly, which led to poor quality and low productivity (the rush to get production going was also to blame, as it shortened training time). Turnover was high and labor problems were rampant – there were over two dozen strikes in one year alone. The factory operated deep in the red throughout its existence and was ultimately closed in the mid '70s after only 13 years in operation.

Suggested By: Fl1ngstam and ranwhenparked

2.) The DeLorean Plant In Dunmurry

John DeLorean might have had a clue about building cars, but his Irish employees certainly didn't. DennyCrane knows what the problem was:

While in theory, it was relatively cheap labor with tons of tax incentives, what it ended up being was hiring thousands of people who had absolutely no clue how to build a car, with inadequate training leading to tons of quality issues. They had to perform extensive quality control testing afterwards, and even then issues still got through.

I'm sure if the company had lasted longer, the issues might have been sorted, but... well, the rest is history.

Suggested By: DennyCraneDennyCraneDennyCrane

1.) British Leyland Longbridge

They built it the wrong way around and they left their garbage all over the place.

Luckily, My X-type is too a real Jaguar's X-Type wasn't built there:

523 union stoppages, ancient infrastructure, utter crap build quality.

The British had to sacrifice a few historic brands to get over this.

Suggested By: My X-type is too a real Jaguar

Welcome back to Answers of the Day – our daily Jalopnik feature where we take the best ten responses from the previous day's Question of the Day and shine it up to show off. It's by you and for you, the Jalopnik readers. Enjoy!