How To Become An Automotive Engineer At A Major Car Company

A question I get a lot from younger readers is: How can I become an automotive engineer for a major car company? The answer is that there are many avenues to that goal, which is why—in addition to telling my own tale about how I scored my dream engineering job at Fiat Chrysler—I compiled stories from Ford, Nissan, Honda, Fiat Chrysler, and GM engineers.

It's the same question I used to ask people all the time when I was a middle-schooler in the small city of Leavenworth, Kansas. I was someone who didn't live anywhere close to the car industry (unless you count dealers and the Ford plant in Kansas City), and knew little about the civilian sector in general, since I grew up in an army community. To me, the automobile industry was a dim light atop the tallest of peaks—something that I could only faintly see from a distance, a dream that mostly just felt like an impossibility.

[A quick note: This article consists of eight pages, one devoted to each engineer's story. Once you get to the bottom of my page, click "next" to read on page two the amazing way that the Jeep Wrangler JL product planner scored his dream gig. Comments are on page nine, which I realize is a bummer. Tell me your thoughts on how this new format works for a long feature like this one. I think it breaks things up well, but I'm unsure.]

Let The Passion Drive You

I was 13 years old, but for years and years, I carried that dream right there in my chest pocket, never letting go and using it to shape each and every major life decision I made.

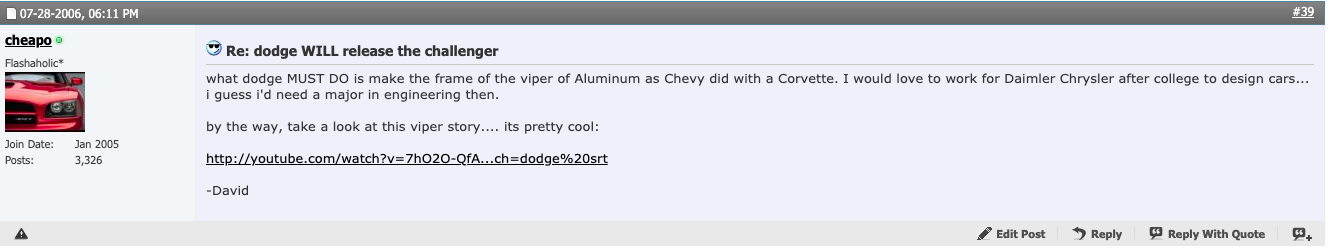

My goal, to be specific, was to work for Chrysler, as I wrote on a flashlight forum (don't judge) post back in July of 2006, when I was a mere 14 years old:

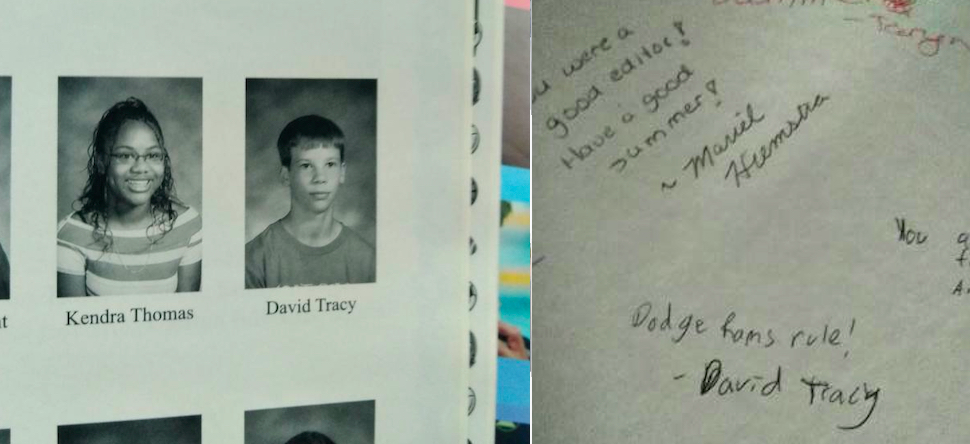

A former classmate, whose dad owned an awesome third-generation Ram 1500 (with the billet grille!), recently sent me a photo of our eighth-grade yearbook, in which I wrote: "Dodge Rams rule!"

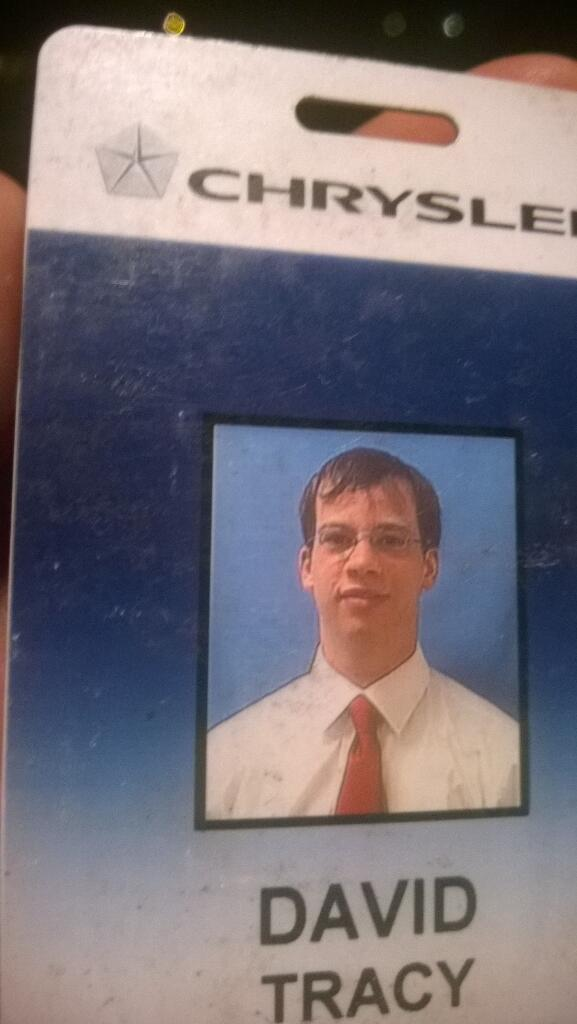

Look at this Chrysler nerd:

I vividly remember a Chrysler Ride and Drive event in Kansas City that I convinced my family to attend, and we always went to the Kansas City Auto Show. Here's my 16-year-old self crawling all over Jeeps in 2008; the JK Wrangler was still a relatively new vehicle, and I was obsessed:

I even took a photo of myself (using a digital camera because this was before the proliferation of smartphones) in the 2008 Jeep Liberty, which—while new at the time—was a pretty crappy Jeep. But a man in love sees no flaws:

Never mind, even I knew a crappy car when I saw one (see caption):

Also new in 2008 was the Challenger:

And the "DS" Ram:

Now that I think about it, 2008 was a pretty mega year for Cerberus-owned Chrysler. Lots of cool new vehicles.

Anyway, you get the idea. I was a kid living in a town in Kansas, absolutely obsessed with DaimlerChrysler to the point where I used to read Chrysler-focused car website Allpar religiously, I wore lots of Chrysler memorabilia (see below), and I even watched Chrysler's "Under the Pentastar" show about what was going on at the company in Auburn Hills.

I knew all about how the headquarters was set up, I knew all about the Chelsea Proving Grounds, I knew all about the Chrysler Institute of Engineering—Chrysler was my holy grail.

This obsession with Chrysler began with a Forest Green 1998 Jeep Grand Cherokee that my dad bought back in 2003 when my family moved back to the U.S. from Germany. I've already written ad nauseam about this machine, but the short of it is that six boys + Jeep + lack of things to do in Kansas = endless fun off-roading = inspiration.

My brothers and I became known in our high-school as the Jeep brothers or off-road brothers, because we often showed up with a machine totally covered in filth.

It was that Jeep, and my absolutely awestruck reaction to the then-new third-generation Ram 1500 (I'd never seen anything like it in Germany—that huge grille amazed me), that made me fall head over heels for the Auburn Hills-based company. My focus, from then on, was fierce.

Study Engineering, Get Involved In Car Things

"Which college should I attend?" is a tricky question. In my case, I got turned down from one school, waitlisted to three, and accepted to the University of Virginia, the University of Kansas, Colorado School of Mines, and maybe one or two others. All of these schools were solid, but I chose UVA because of its reputation for good academics, its affordable price tag (I was technically "in state" despite not having ever lived on the east coast, since my army dad was from Virginia originally), and above all, the fact that I got waitlisted by my top choices.

I'm not sure what sort of guidance to give on this whole college choice question. My general philosophy is to pursue the most difficult option whenever possible, but you'll also want to consider the engineering opportunities that the school offers. Does the college have any sort of relationship with automakers? Are there cool car clubs like Formula SAE? Do many people from that school go on to work for automakers? (Alumni networks are a big deal.)

I attended a school with a relatively small engineering program, which really put me at a disadvantage when it came to recruiting, as the big OEMs did not headhunt on our campus. I was later accepted as a transfer to Cornell (one of the waitlist schools, and the one I'd initially wanted to attend due to its more established engineering program) after my second year, but stuck around at UVA based on a gut feeling, and the fact that, academically, I had hit a nice stride.

In college, I studied mechanical engineering with a minor in aerospace. I studied hard, attended office hours if I didn't understand something, chose most of my classes based on the reputations of the professors, and always tried finding parallels between my coursework and automobiles to stay motivated. (This wasn't particularly difficult, as cars are complex and designing them requires a good grasp of fluid mechanics, dynamics, material science, aerodynamics, mechatronics, and many other engineering areas.)

I got involved in Baja SAE, mostly to learn how to wrench in my spare time. (I welded for the first time at the Baja SAE airplane hangar.) I also took an Electric Vehicles capstone project, which I'll write a full story about later. (The short of it is that my team tried to convert a VW Jetta into a mid-engine, electric convertible with a manual transmission.) Plus, I started and ran my own car club called the Virginia Automotive Club.

We met every week to eat pizza that I bought from Little Caesars with money I had won in a college writing contest, and we chatted about what we'd read on Jalopnik, Autoblog, and Motor Trend. We played hangman, charades, and a number of other games where the answer was always some obscure car. I organized trips to the Insurance Institute for Highway Safety and the D.C. Auto show (see images above and below), and I even taught members how to do basic maintenance on their vehicles in the football stadium parking lot. We had an "incident" once that involved spilling six quarts of oil on that lot, but that's a story for another time.

In the end, the "Virginia Automotive Club," as I named it, was just a club for people who loved cars and the car industry. I stood up at the front of the classroom each week and usually improvised, talking about recent car news, and getting people's opinions on certain auto topics. It was a safe space for people to just geek out about cars.

Apply For Internships, Use Your Contacts To Get The Dream Gig

The first summer out of college, I was a counselor for a math and science camp. The following summer, I snagged an internship at Cummins Diesel Company as a project engineer in the Advanced Engineering Mechanical Development team, where I worked to diagnose and repair a rig used to test pinion gears on diesel engine Waste Heat Recovery Systems. They extract mechanical energy from exhaust heat by boiling coolant across a turbine, in case you were curious.

I got that internship by applying through my engineering department's recruiting website. Having recognized Cummins from my obsession with Chrysler, I put everything I had into that application. I think, though, that the pivotal player in getting me that job was my 1992 Jeep Cherokee. (I'll explain why later.)

I had an incredible summer hanging out with hundreds of engineering interns in the small town of Columbus, Indiana. We did a lot of road-tripping and partying—including at the 2011 Indy 500—see above. But as great as Cummins was, I still had my sights set on Chrysler.

I pursued Chrysler through a number of avenues. First, I asked a Texas A&M intern whom I'd met at Cummins, and who had spoken with a Chrysler recruiter, for that recruiter's contact information. If Chrysler wasn't going to headhunt at UVA, then I'd have to get their info from someone at a school where Chrysler did headhunt. I also reached out to Jalopnik editor-in-chief Matt Hardigree, whom I'd befriended, since he lived near my tiny college apartment. He sent my resume to his PR contact.

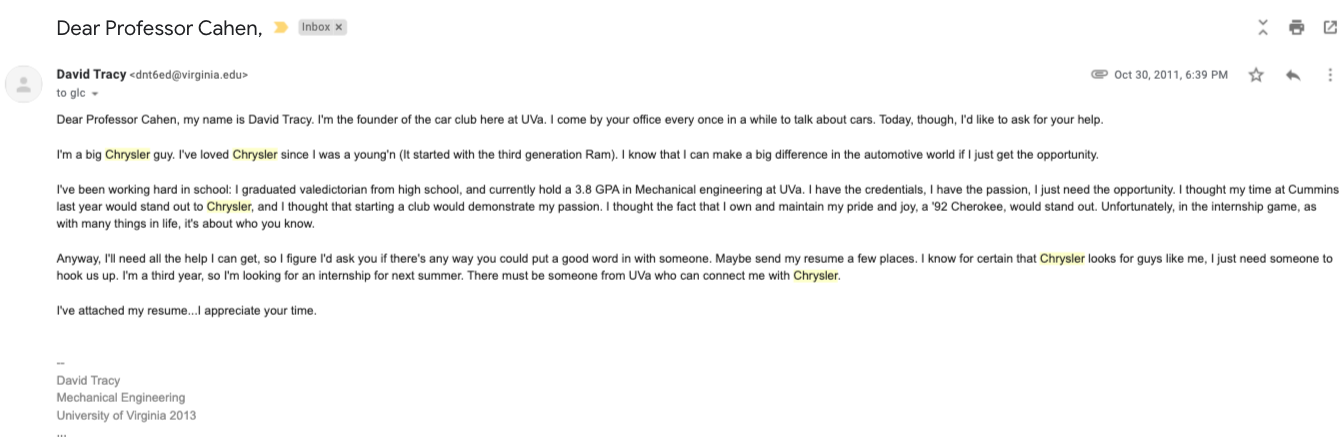

But then, as time went on and desperation sunk in, I drafted an email, and sent it to all of my professors, hoping that someone—anyone—might have a contact at Chrysler. Here's the email that changed my life. It's not a particularly modest message, in retrospect, especially considering my lack of experience. But it did work:

Three days later, my resume was in the hands of someone at Chrysler, and I was ecstatic:

After absolutely crushing the interview thanks to my ridiculously deep knowledge of the company and its products, and also discussion about my Jeep—more on that next—I experienced a euphoria like none I have ever felt before or since:

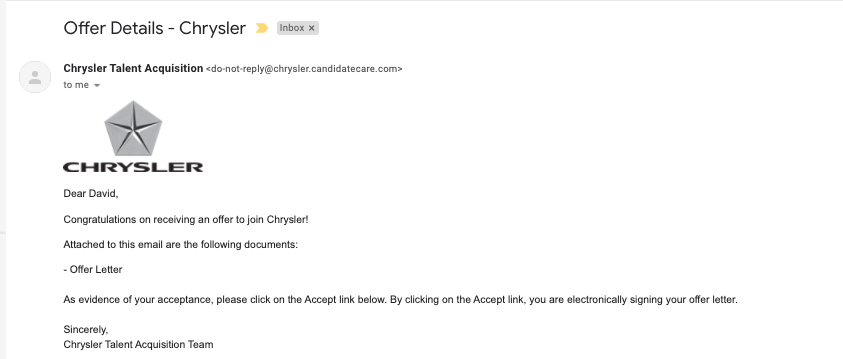

I couldn't contain my excitement:

That silly Facebook post above hasn't aged well, but I was 20, and I was excited to finally achieve a true dream that had been in my heart since I was just a young teenager off-roading in the woods with my brothers in Fort Leavenworth, Kansas.

I can still remember the moment I opened that email from Chrysler Group, LLC's Talent Acquisition Team. All the doubts I'd had about the choices I'd made, the school I'd gone to, the activities I'd joined and not joined—they were all gone. I had done it.

Buy An Old Car

Before I finish this story, I cannot downplay how important my $1,400, 225,000-mile Jeep Cherokee XJ was in helping me get that gig. Because of its age and mileage, the Jeep forced me to spend every waking moment that I wasn't studying, not going out with girls as I should have, but rather wrenching on that Jeep (some things never change).

The benefit of this was that I not only got extremely well-acquainted with how cars work, but my wrenching stories were a hit with both the Cummins and Chrysler recruiters. Both interviewers loved hearing about my old junky Jeep and recent repairs, so I have to give some credit to the shittiness of my 1992 Jeep Cherokee for helping me get those internships and my full-time gig at Chrysler.

Never stop being unreliable, you beautiful old box.

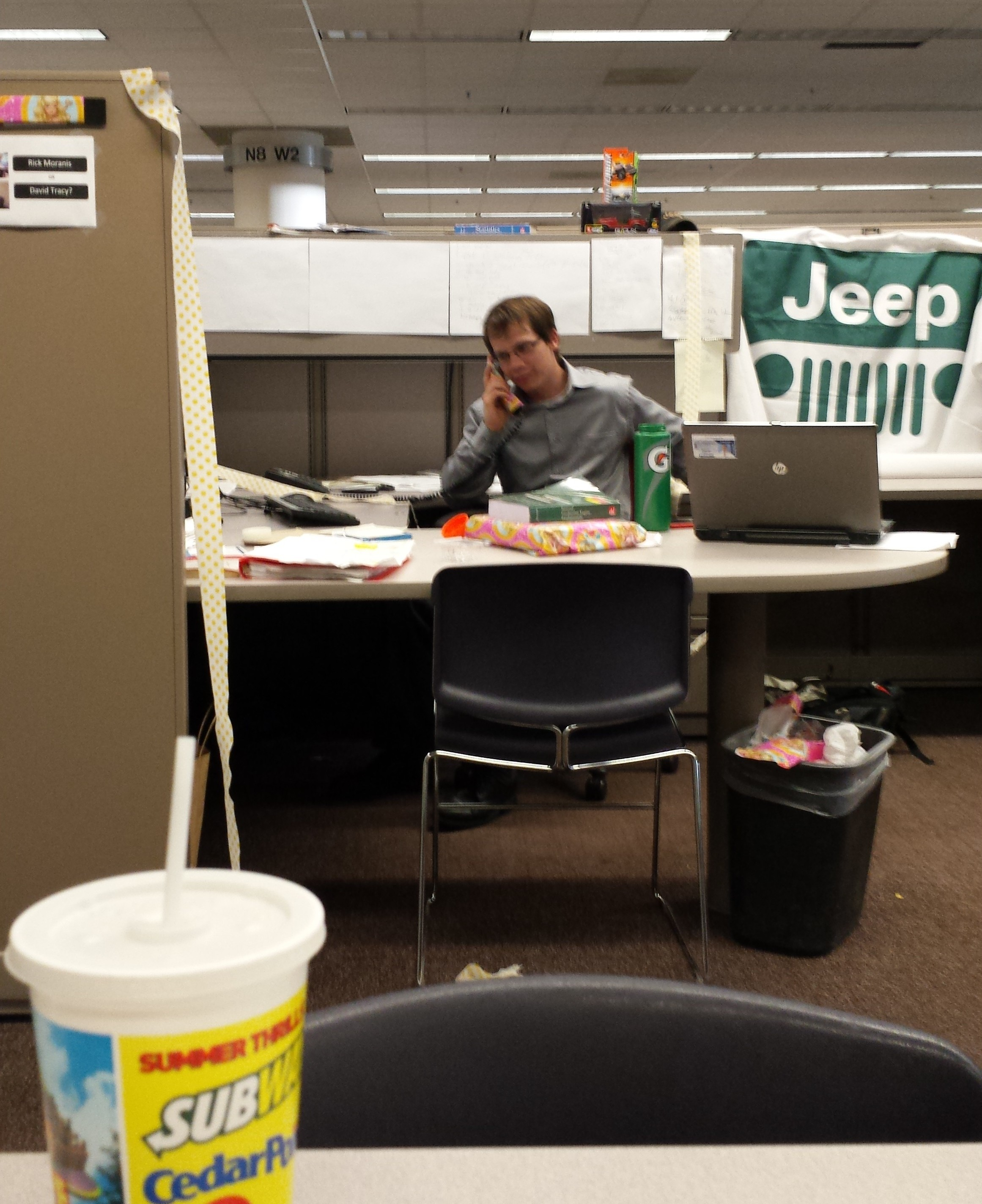

After the internship in the packaging team (Advanced Concepts Engineering, it was called then), I got a full-time offer, and serendipitously joined the company just as it began development on the new "JL" Jeep Wrangler. (I've written a bit about that experience here.)

I remember when my boss asked my team: "Okay, so here are your options for vehicle programs in need of a lead cooling system designer: KL/K8 (Cherokee/Grand Commander), RU (minivan), DT (Ram), WK/WS (Grand Cherokee/Grand Wagoneer), L-car (Charger/Challenger/300), Viper, Wrangler, and a few more." Nervously and slowly, I glanced around. I knew what I wanted, but I figured everyone else would be after it, too.

To my surprise, the four other people on my team didn't have a preference! (One thing I learned early on while working at FCA is that most people there are not actually diehard car enthusiasts.) Within just a few weeks of starting at FCA, I was cooling system lead (Systems Integration Responsible) for the new Jeep Wrangler. (I also asked for Viper, but the program was canceled.)

Working at Chrysler had always been my dream, but working on Wrangler specifically? That was like a dream within a dream. It was automotive Inception.

Ford, Chrysler, Nissan Engineers Tell Their Stories (See Next Page Of This Story)

Okay, so now you know how I became an auto engineer. Basically, it was a blend of focus, hard work, and luck, though I have to also acknowledge the fact that—aside from our frequent moves—I was lucky enough to grow up with decent stability, particularly in the areas of family dynamics and finances.

But if you're looking to get into the auto industry, hearing from just me isn't going to do you much good, which is why I've gathered some stories from old coworkers, friends, and readers. Those are on the following pages, and I'm sure other engineers will post their stories in the comments. Hopefully you can draw some takeaways from these, and come up with a plan to get yourself into the exciting world of automotive engineering.

Click on the arrow below to read fascinating stories from Ford, Chrysler, Honda, and Nissan engineers. The first is titled "How A Lifelong Jeep Fan Became The Jeep Wrangler JL Product Planner."

It's a hell of a tale.

How A Lifelong Jeep Fan Became The Jeep Wrangler JL Product Planner

I met Tony Carvallo at Chrysler while I was under my Jeep changing the transmission fluid in the Technical Center parking lot. "Hey dude," he said in his clean work clothes. "Need help?"

"Naw, I'm good," I told him, "but thanks."

"No, seriously dude, I'll come down there right now and help." I told him I was almost done with the job, but thanks anyway.

The following day, I walked to his desk, as I'd recognized him from my office suite. I thanked him for offering to help, and then realized that he was kind of a big deal: the Jeep Wrangler JL product planner, Tony Carvallo. A legend, really.

And part of that legend is a product of how he got to Chrysler. I wanted Tony to tell that story like he'd told me before, so I called him up for an interview.

Tony grew up in Windsor, Ontario loving Jeeps. "I've loved Jeeps ever since I was roughly 10 years old. I got a magazine from my dad when I was in the hospital... It was a Four Wheeler Magazine, and it was amazing to me... I thought that was so cool, and I wanted to build Jeeps," he told me.

He spent his childhood wrenching and reading. "I did everything possible to take things apart to learn how to build a Jeep," he said. "I always felt that that would make me a stronger candidate by the time I had an opportunity to work at Jeep."

He built go-karts, and basically lived at the junkyard. "I would spend every Saturday for hours on end at a junkyard... I was actually taking apart old Jeeps and trying to understand the bearings and axles and shafts."

Tony—whose nickname for me is "Tink Tink," since he met me while I was tinkering on my Jeep in the Chrysler HQ parking lot—was torn on whether to get a traditional engineering degree, because he wanted to focus on what he loved: hands-on work.

"That's part of an education that makes me a little bit more unique maybe," he told me. Tony didn't get a traditional mechanical engineering degree, but instead chose to get a Mechanical Engineering Technology diploma, which gave him hands-on skills like CNC machining, plus it taught him drafting and got him a Computer Aided Design (CAD) certificate.

All the while, he was building a Jeep, and assembling hybrid axles and transfer cases. And this all happened during a time when the internet was in its infancy, so Tony had to learn many skills on his own.

Okay, not completely on his own. Tony attributes some of his learning to Four Wheeler magazine, the Advanced Adapters catalogue ("That was my guide when I was a kid" he told me.), and later, write-ups by someone named Bill Vista on the website Pirate 4x4.

Though Ford was recruiting at his school program, Tony had his mind set on his goal. "I was so set and determined that I'm going to work at Jeep. I was sending my resume over and over and over again... I don't know how many times, but a lot," he explained.

But then, thanks to Chrysler using a Computer-Aided Design program that Tony was well-versed in, the Canadian got his chance.

"Never got a response until one day, and that's because I have a Catia certificate, and it just so happened that back in [the late 1990s] the whole company moved to a... software program called Catia, and that was just the right ticket."

The job interview was for a position as a CAD designer for Jeep electrical connectors. Hardly sexy, but as Tony put it "I didn't give a damn what the hell I was doing... to me, I just wanted in."

At age 24, Tony showed up the hallowed Jeep Truck Engineering facility in Detroit with a wacky plan. He didn't want to show the hiring manager a standard resume, because he didn't see value in the company knowing he delivered pizza and served beer on campus. He wanted to communicate to them his love for Jeeps.

Speaking of his resume, Tony told me over the phone: "I put my name, I put my school, and then I said 'And this is all I did with my Jeeps' and I listed everything that I built, rebuilt, and engineered on my personal Jeep components and Jeep stuff."

"They wanna know that I know Jeep stuff. So I just listed everything," he said. He wrote about how he created a hybrid Dana 44 axle using Chevy, Jeep and Ford components. He used a Dana 44 center, truck parts at the end, and created a "high steer" system.

"I wrote that all in detail and how I did it. I created my own transfer case using parts of all the other transfer cases."

"I wrote it all down, put my suit on, went to the interview, and sat down with the guy. I slid over my resume, and he looked at it. He kinda was baffled."

"Kid you're in the wrong interview," the man sad. "This job's not for you." Tony's heart sank. But then, "I got another guy I need to introduce you to," the man continued.

"And he walked me over to another level and over to a large glass cube, which is obviously directors and above," Tony recalled. The man looked at the resume, then "drilled [Tony] with some technical questions about Jeeps."

"I answered them quickly," Tony said.

The man asked about Tony's thoughts on axle noise, to which Tony asked "Which axle?" The man said the Jeep Grand Cherokee Axle.

Tony, knowing that the Grand Cherokee's Dana 44A rear axle has an aluminum center section, which allows for deflection, which can affect the gear mesh pattern and cause noise, said he was baffled with the aluminum design. He also said the axle could have used an additional bearing.

As Tony rambled, the engineer stopped him. "Kid, kid, kid, stop. You're hired. When can you start?"

Tony got his job as a Durability Testing Engineer for the Jeep Wrangler, and started on the Monday after the interview. "I ran home like Forrest Gump."

"Even when I tell that story I can't believe that actually did happen," Tony told me, clearly emotional about how he achieved his childhood dream.

After that job, Tony had some other standout roles at Chrysler and, as Tony recalls, they were given to him. He didn't even have to apply. People respected and knew of his knowledge, so they offered him awesome Jeep-related roles, including the JL Wrangler product planning gig.

Tony credits success, in large part, to his determination, and his ability to capitalize when an opportunity came by being knowledgeable and passionate.

Co-op And Rotational Program Gives Michigander An Amazing View Of A Major Car Company

My friend Rochelle has a fascinating story in that she's seen so much at such a young age.

A daughter of two physical therapists, Rochelle grew up in the Lansing area, and went to a medium-sized high school of around 250 students per class. She took lots of AP courses, and focused much of her schooling on STEM areas, in part because of a lifelong adroitness in math and science.

Though nobody in her family was an engineer, Rochelle decided that—since her squeamishness around blood made her less than ideal for a medical profession, and since an older friend had recommended Kettering University—she'd be headed to Flint to study engineering.

Formerly known as General Motors Institute, Kettering has a storied history in the auto industry, to which the school's engineering graduates have made enormous contributions over the years.

One thing that Rochelle really enjoyed about the school was its co-op program. "It was a way to see what it was really like before having to commit to a career in it," Rochelle told me. This was helpful, since she had no idea what it was like to be an engineer.

The co-op program involved alternating 11-week school terms with 12-week periods in which Rochelle gained work experience at Chrysler. Rochelle thinks it's a great system. "You're putting yourself so much further ahead of anyone else your age," she told me, saying her first job ever was working as an engineer at Chrysler a week after she turned 18. That's nuts if you think about it.

Another point that Rochelle made during our interview at a sandwich place just a few minutes from the Chrysler Technical Center was that being well-spoken and remaining active socially (a tall task for some engineers, if we're honest), are keys to success. "The alumni base is so strong, especially in this industry," she told me—a fact that I knew very well from having interacted with scores of former Kettering students during my time at Chrysler.

You may notice in a few of the other engineers' stories (including mine) that interviewers were impressed by knowledge of Chrysler and its products. In Rochelle's case, she wowed them with her academic skills and interests, not so much her knowledge of the company's vehicles. "I didn't know what cars Chrysler made, so I said I would prefer a yellow one," she said—hilariously—when asked by the interviewer which Chrysler product she likes most.

Rochelle focused on aerodynamics during her time as a co-op. She worked in the AeroThermal team at Chrysler, and ended up writing an undergraduate thesis on boundary layer airflow.

"I was able to help influence the design of the cooling system of a past vehicle," she said of her time as a ridiculously young engineer. In college, she tore apart engines in an internal combustion engines class, she visited the EPA's test center in Ann Arbor and learned about coast down testing, she took an elective that involved dismantling a transmission, she learned about alternative energy in her coursework, and the list goes on.

At 21, she entered the Chrysler Institute of Engineering rotational program, which involved doing short stints in various areas of the company while simultaneously earning a Chrysler-funded master's degree.

She did seven rotations in addition to the six as a co-op. Rochelle worked in Vehicle Integration for SRT and did electrified powertrain work on the JL Wrangler. She worked at a plant where she "got to help alleviate launch issues," she spent a rotation in the quality team, she spent time out of engineering on the Jeep brand team, and the list goes on.

Thanks to her co-op programs and CIE, Rochelle has seen more of Chrysler by age 25 than some will in their entire careers.

Ford Engineer Takes Imperfect Jobs On His Way To The Dream Gig

This one comes from a Ford engineer who wanted to remain anonymous, as car engineers are usually careful about speaking with media, mostly because Major OEMs tend to want folks to be "media trained" prior to showing up in publications:

1) I was a starry eyed young teenager and I wanted a Ford Mustang GT. I didn't even understand the implications of trim levels or what powertrain levels meant at this point in terms of power and performance. I nagged my parents literally forever. I didn't know why I liked it, I just knew that I had to have it and I wasn't going to let pedantic threats stop me.

2) I turned of age to drive, and worked multiple jobs. My first car was a 1992 Ford Explorer that my parents bought new. It had seen better days but it was still serviceable if you didn't count the lack of AC and the fact that it got HOT those summers. I was cutting grass for multiple neighbors from when I was 12 and saving most of my money. I worked at a tennis club where I woke up at 4 to 5 AM on most of the weekends and resurfaced tennis courts early in the morning. The manager of the tennis club knew the owner of another local restaurant. I ended up also working many nights at the other local restaurant.

3) My father agreed to split the cost of a car when I was 17. He desperately tried to talk me into a Honda Accord, I'm not really sure why but that was his opening negotiation. I didn't budge and finally he resigned that, after having test driven a bunch of cars I didn't want, I was allowed to split the cost of a beautiful SN95 Mustang. She had 27k miles and was from 2003. She was a V8 and AUTO which I later learned was a major mistake (more on that later).

4) This vehicle became an important touchstone on many aspects of the story. (Took the car to do this, went on a trip with the car to do that.)

5) The car didn't come without string. My father had agreed to pay for all of the expenses from the Explorer (it was "his car"), however when I got "my own car" I had to take up the expenses. So I had to do all of the maintenance and overhaul. So me being 17 and frustrated, and having a young engineer's brain, got me thinking "Damnit, if this wasn't like this it could be so much better for maintenance." Eventually I got into more involved changes and upgrades to the point where I was like "goddamnit the MF that designed this is an idiot and literally a blind guy can do better." So at that point I decided to be an automotive engineer. (Concurrently I was also coached into picking something other than the performing arts by my parents—I wanted to do music—but thats OK). I decided I wanted to work on cars. Not just work on them; I wanted to make them better, more serviceable, and found enthusiasm in improving the customer experience for the person that wants to own their vehicle and turn wrenches on it themselves. Also I wanted to work on Mustang, I knew what I wanted, but the path involved many zigs' and zags

6) I worked my ASS off at the second half of my high school. Totally changed everything. Dropped out of sports, added AP math, physics, and I started running. (A lot.) I formed new relationships with teachers in STEM where I otherwise would have had more of a casual relationship. I started coming home from school and instead of practicing music, I was doing homework and extra study problems. I attended homework groups for my classes, and I did bonus problems for fun. Then came time to apply for schools. I sent in a half dozen applications; I was initially undecided by my undergraduate alma mater but eventually they accepted me. It's good, too, because I don't know if I would have applied myself as well otherwise.

7) I worked my ass off in college, I joined an engineering fraternity but occasionally abstained from social gatherings. (Honestly I'd love to repeat the whole process as a communications major.) I probably could have done better, but it would have been harder. Engineering school is so hard and stressful, I don't know how it would be possibly to apply yourself more. I started immediately trying to get internships and co-ops during my first year. Frequently I was greeted with "Hey, we're glad you applied, you seem to have great skills, but we were looking for someone in their 2nd... 3rd... 4th... years." I kept up my effort. Eventually VERY early in my second year I got an interview for an internship at a company manufacturing truck seats. (I CANNOT STRESS THIS ENOUGH: DO NOT TURN DOWN YOUR NON-IDEAL JOB if you don't have something better lined up.) These jobs are ones that will let you cut your teeth at what you do well. They hired me on for 3 to 5 months. It wasn't the job that I wanted to do. It wasn't the product I wanted to work on. It wasn't the company I wanted to work at. But It got me needed experience that I was able to use to get my foot in the door at my next jobs.

With this experience I was able to get an interview and an internship for a job at a defense contractor. At the time I decided that I didn't really like building things that blew people up, at least as much as I did cars. My former internship called me back and invited me back to work for a while. I re-negotiated my hourly rate and worked for them while taking classes for a year. So I worked there while taking classes full time. This continued on for a while. In total I worked for this company, which was not my ideal job for a year. It was good experience, I had freedom to work on meaningful tasks.

Finally moving into my last couple of years of college, I landed an internship at a chemical company in north central Michigan. I had a really good internship, accomplished tasks which were very challenging. Ultimately they didn't offer me a job. It was disappointing because in terms of delivery for many of the interns, I had deliverables that were achieved to many higher-ups that my peers weren't held to. They just didn't hire a lot of mechanical engineers that year because of the economic situation. In retrospect I understand that as a Mech-E.

I found out later than I would have liked to that they weren't going to offer me a job in my super senior year. So I stopped EVERYTHING that didn't have something to do with me getting a job. I stopped going to most classes, I stopped doing homework, studying, etc. The MOST important thing that you're going to do with your degree is get a job so I made that a priority. Eventually after one or two interviews, I had an interview with Honda where I was impressed enough that I had decided to go work for another company, other than the one that I originally had wanted to work for.

So I worked on improving automatic transmissions for several years. I vehemently oppose automatic transmissions of any kind, but in one of my former roles I was required to improve the manufacturability of them. To be clear, this caused some significant cognitive dissonance for me. I oppose automatic transmissions. My last four vehicles that I owned have not had automatic transmissions, and at least at this point, since 2014 I have not purchased or intended to purchase any vehicles with automatic transmissions. This whole activity is something that I opposed the entire time I was working on it.

While I was working at Honda, I maintained my view of the future. I obtained an engineering masters from the university of Cincinnati. While working, I waited another nine months and then at that time decided to pursue an MBA. While part way through that MBA I determined that I wasn't going to achieve the salary goals that I wanted, nor the professional goals that I wanted at my current employer. So I started looking around. Coincidentally I was able to find a role working at the company that made my favorite product, and also that I would be working on that product. It was literally a job too good to be true.

To conclude: my parents let me purchase the vehicle that they felt was irresponsible and it literally changed my life for the better. I think if they had forced me to get a Honda Civic... I honestly don't know who I would be, and that sounds dramatic and weird, but I really don't know what I would have done given THAT UNIVERSE....My parents fought with me and eventually conceded on a vehicle that I Wanted to purchase when I was 17. Who knows what I would be doing right now.? I don't think I would have picked engineering.

Michigan Native Never Intended To Be An Engineer But Wanted A Challenge, Scored Jobs At FCA And GM

From my friend who has worked at FCA and GM:

My great-grandfather was a car mechanic, my grandfather worked as a mechanic while going to school for Mechanical Engineering, and my father is a mechanical engineer who always turned a wrench or two growing up. Cars and engineering talk was always in the background at family gatherings.

Growing up mostly in metro Detroit, with the exception of four years spent in El Paso, Texas, I never intended to become a mechanical engineer. I went to Wayne State University in Detroit, Michigan. It had/has a decent engineering program, but that didn't factor into my decision at all. I got basically a full ride academic scholarship, and I had the opportunity to continue swimming at the collegiate level. In fact, I didn't decide to become a mechanical engineer until shortly after the conclusion of my second year in college.

Until then, my chlorine-saturated life was filled with a haze of various liberal arts classes: Women's Studies, Anthropology, Geology, Intro to Criminal Justice; the list goes on. In all honesty, I think I was looking for more of a challenge when I decided to try out engineering, and I wanted to learn more about cars. Plus, I figured that even if I couldn't find a job in engineering, the skills and knowledge would apply to other jobs. As always, I was looking to keep doors open for myself since I wasn't confident in my decision.

There weren't a lot of student-athletes in engineering, but one of my really good friends on the swim team secured an engineering internship with Chrysler. Naturally, that was intriguing to me, but I was too late to get into the Chrysler internship program that year. Like most things in my college career, I was a little late to the party but willing to make up for it. My first engineering internship ended up being with a privately-owned friction materials testing lab in Detroit. I learned a lot in that job; however, I was hungry for a shot to work with the full vehicle. That Fall, I applied for an internship at Chrysler.

My internship turned into a full-time offer with Chrysler, soon to be FCA. I ended up working in a couple of different positions within FCA for almost four years before leaving to go to General Motors, where I've been for just over two years.

I’m Not Even Sure What To Say About This

From my friend who worked at Nissan is a bit silly, as he described his career path in a rather "special" way:

Now, this is a story all about how

My life got flipped-turned upside down;

And I'd like to take a minute

Just sit right there

I'll tell you how I got in the automotive world;

In the Boston area, born and raised

Tinkering with shit, most of my days;

Chillin' out maxin relaxin' all nerdy

And making potato cannons in the backyard;

When a physics teacher who was an engineer

Said make a catapult and try to hit a quarter;

Well me and my friends who were up to no good

We read the rules and did what we could;

A marble shootin' air cannon is what we made

We were denting the quarters;

My teacher said fine but you outta know

Engineering is where you gonna grow;

I studied and applied to engineering school

Got in to Villanova like some kinda fool;

I packed my suitcase and went on my way

Kissed my mom and caught a train

Off to Philadelphia to make my name;

Philly cheese steaks and learning to drink

Didn't give me much time to think;

After a while I thought real hard

To the Midwest for jobs with cars!;

Ohio State is name on the degree

Mechanical Engineering was right for me;

Spent too much time on my capstone

Automated a manual transmission for EcoCar

Trying to make a Malibu go far;

Didn't work to apply for a career

Graduated OSU with no job near;

Called up a recruiter and my internship post

Dolled out my resume real fast;

Had two interviews in no time at all

Honda and Stoneridge both made offers

Rural Ohio was where I would fall;

I went to Stoneridge and got real bored

I am a city boy who needs more cars

So my boy Derek called up one day

And said "Hey man, work at Nissan";

So I thought what can I say

I take a look and apply for fun;

I got the job and wanted a GT-R

So off to Detroit, its not too far;

I looked at my kingdom

I was finally there

To sit my throne in a brand new car

No Connections But Life-Long Passion Got Rural Ohio Kid Jobs At Two Major OEMs

My friend wrote about his journey from Ohio to the Motor City:

I may have written this in a bit of dramatic fashion but the feelings are all real for how lucky I feel to be working in the automotive industry. Hope you enjoy!

Imagine growing up in the middle of nowhere Ohio and knowing no one with connections to automotive companies whatsoever. That was me growing up, but I was guided by the passion for cars I developed from the many car shows, race tracks and automotive movies during my childhood. I was raised in a middle class household with both parents working normal 9 to 5 jobs. Heck I didn't even meet an engineer until I was in high school. I chose to pursue mechanical engineering with the only goal of one day working for an automotive company and that drove me through college. I remember my family driving past the Ford headquarters during a family vacation in Michigan when I was in middle school and thinking how great it must be to work there.

I got my first taste of Detroit when I was hired as an intern in the Summer of 2013. I was amazed by the inner workings of the automotive industry and it felt special to be surrounded by prototype vehicles and working with engineers who were responsible for the vehicle engineering. That was my foot in the door and from there I have worked for two automotive companies over the last six years in chassis engineering.

I have had many unique experiences such as working in a foreign country for two months and being responsible for a vehicle's chassis characteristics. It still amazes me that the kid from in the middle of nowhere Ohio grew up to engineer vehicles that are on the road today. I found myself working in the automotive industry by working hard, getting myself in front of the right people and maximizing the opportunities I was provided.

Plainly put, if you are passionate about cars and you are willing to work hard, companies will see that and want you to be part of their organization!

Getting Familiar With The Honda Recruiters And Oh Yeah The Trebuchet

Here's Matt Hetzel from Ohio:

I went to school at Youngstown state university for mechanical engineering. Since I was small, my goal has always been to be an inventor, so when I chose to go into engineering because I thought it would give me a good skill set to accomplish that goal. I started getting into cars my senior year of high school and after I started learning about all the amazing engineering behind the scenes I decided I wanted to work for a car company. Unfortunately, for my first two years at YSU, there were no major car companies at the co-op expo. I was limited to applying for summer internships online. Those searches came up fruitless so I found a non-automotive internship.

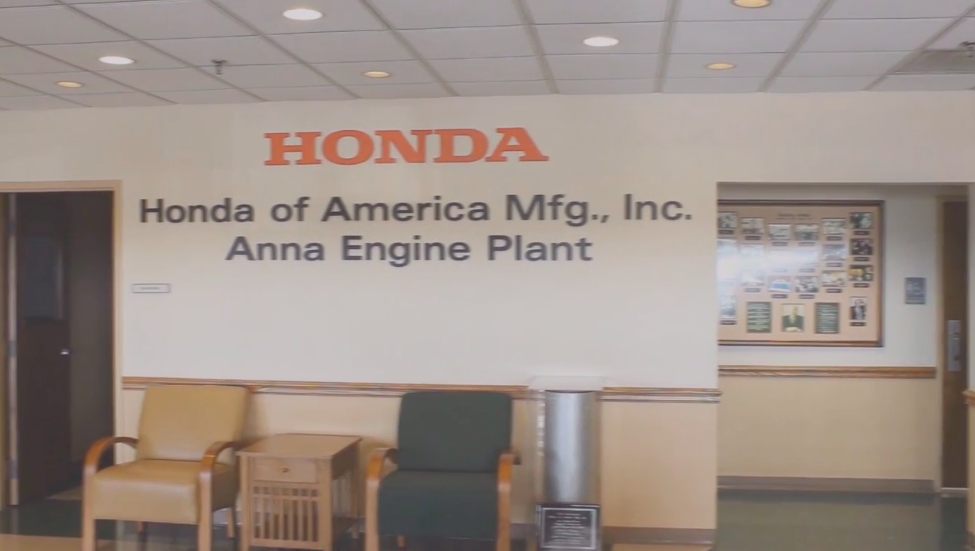

My junior year, Honda came to the career expo for the first time. I made sure to go to every extra talk that they were at so that I would be a familiar face by the time I actually went to the expo. It seemed that worked because when I talked to the HR rep at the booth, he already recognized me. I got an interview on campus and then later a phone interview with my future manager and I got the job! Finally, after interning for over a year with R&D and graduating from YSU, I got hired on full time as a mechanical designer at the Anna engine plant.

When I talked to my employers about what made them choose me, several of them mentioned aspects of my personal section in my resume; I am an eagle scout, I like to work on cars, and I built a trebuchet. These are the things that seemed to make me stand out. I also talked to a Honda recruiter who didn't recruit me, but who was in charge of hiring both interns and full time engineers. He said that he goes through hundreds of almost identical resumes in a day so he recommended doing something to make yours stand out. I definitely agree with his recommendation, and I think that the most important part of the resume is probably the interesting details about you that say you're a real person and not just another resume.