How I Got My $600 Diesel Manual Chrysler Minivan Running And (Sorta) Driving

A miracle has happened. The 250,000 mile diesel, manual Chrysler Voyager that I bought sight-unseen in Germany for $600 actually runs and drives. Here's how I made that happen and what problems I discovered after getting the machine on the road.

After reading last week's "Here's Everything Wrong With The $600 Diesel Manual Chrysler Minivan That I Bought Sight Unseen In Germany," you may have shaken your head a few times.

It's a fair reaction, really. Buying—sight unseen—a cheap van outfitted with a VM Motori diesel engine known for its mechanical maladies, and expecting to live in the vehicle for a month while driving thousands of miles around Europe is either foolish or ambitious, depending upon your perspective. The fact that the blue, 1994 van that I purchased is plagued with so many issues would probably make most folks lean toward the former. Still, today I come bearing great news: My friends and I have cured my van's biggest ailment: The engine now runs!

And the van even drives, sort of.

This was my first time working on a diesel, but I'd been doing some reading and surmised that the likely culprit behind why my 2.5-liter turbodiesel's struggled was the diesel injection pump.

Old diesel engines like mine are incredibly simple. There's no spark plug to control ignition timing. Exactly when the engine fires is controlled by a mechanical fuel injection pump whose operation is tied to the timing gears (which are mechanically linked to the rotation of the crankshaft and camshaft, which control piston and valve position, respectively). In other words, the pump makes sure fuel gets injected at exactly the right time in the four-stroke cycle (right after intake and compression, the latter of which builds internal cylinder temperatures high enough to yield spontaneous combustion of the diesel fuel once it's injected).

The problem I was having with my Chrysler Voyager, and likely the reason why my friend Andreas was able to buy it for me for only $600, is that the motor turned over, but didn't fire at all. Listening to the engine crank, it did seem to be building compression, telling me the problem had to lay with the diesel injection pump. Specifically, I suspected there was air in the system.

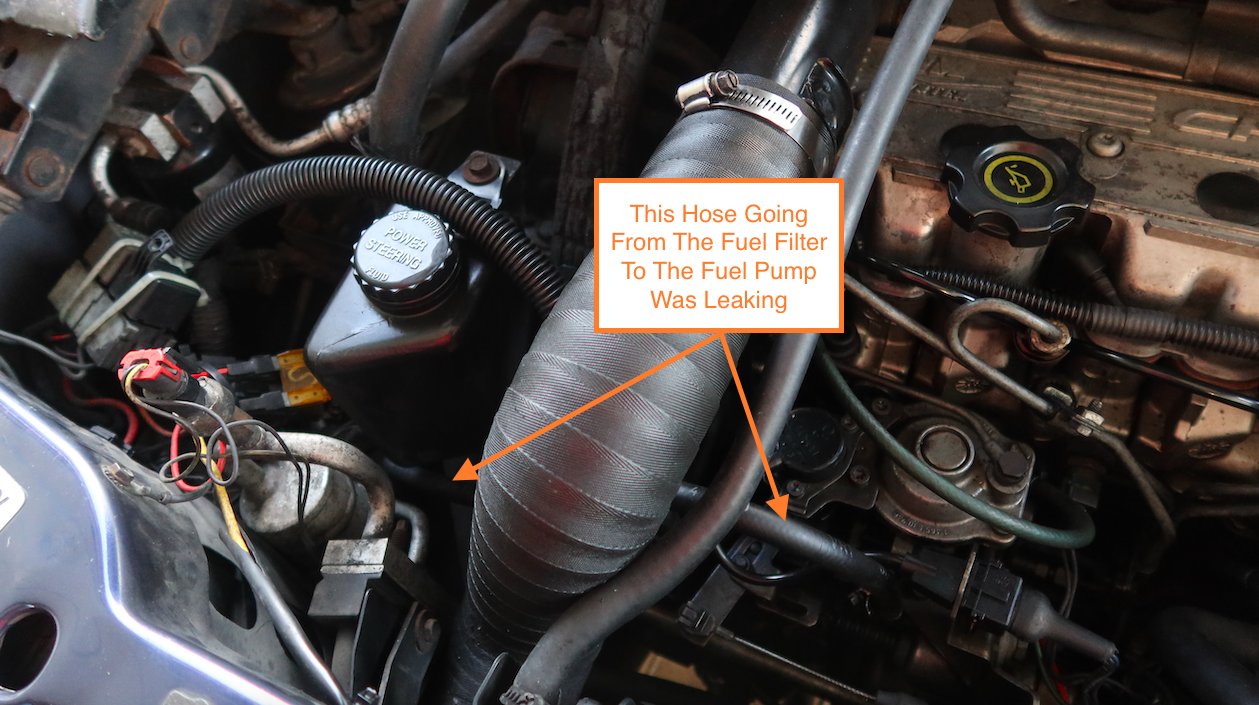

The first thing I did was look at the hoses going to and from the pump. One looked wet, so I yanked it off, and took it to the store to be matched up. Unfortunately, car parts stores in Germany aren't as plentiful as they are in the U.S., and they sure as heck aren't as well-stocked with Chrysler minivan parts (this isn't surprising, really). So I had to order the hose with plans to come back another day.

But I was impatient. I took a close look at the hose I'd taken off, and saw that it didn't look too bad. There was a little cut in one end, but besides that, I didn't see any dry rot or holes, so I just installed the rubber tube between the fuel injection pump and the fuel filter, shoving it a bit farther onto the fuel filter fitting than before. Then I installed a new filter.

This wasn't particularly difficult. I just had to take the front passenger-side wheel off, along with some of the wheel-liner fasteners, as the spin-on-style diesel filter is situated just behind the front bumper.

With that new filter in, the next step was to pull fuel from the gas tank, up through the filter and into the diesel injection pump. This is where pure serendipity made things a lot easier for me than I could possibly have expected.

Meet Loyal. He's a self-described "farm kid" from the U.S. (he's lived in rural parts of the country, including in Kansas, Wyoming, Montana, and Washington, and he's worked on all sorts of farm equipment), who just happens to work for a company in Erlangen, the location of the garage I'm sharing with my friends here in Germany. Loyal reached out to me on my Instagram after my introductory article on this van. "A friend from the USA just sent me a message with your link, I'm in erlangen and I'm sure you have access to tools and such being as you are from here," he wrote. "My German is nicht gut. But I'm happy to spend an evening or two getting dirty with diesel leaks if you need more hands :) just did a trip like this in the USA last summer."

What a kind offer! And, since, in my opinion, the greatest joy in life is meeting new people, I was thrilled to make Loyal's acquaintance. The weekend before this past one, Loyal showed up, I introduced him to my friends here at the shop, and he jumped straight to work.

I'd just installed the fuel filter, and now it was time to get fuel from the tank up through that particulate/water-remover and into the fuel pump. As you can see in the image above, Loyal began with the "old school" method of fuel siphoning; he used his lungs to create a negative pressure. "Oh, these lungs have seen plenty of automotive fuel," the incredibly kind, random farm-guy who just happens to now live in Germany assured my friends and me.

After filling his lungs with diesel vapors, we eventually found a nice hand-pump, which we attached to the fuel filter outlet hose, and in no-time, we had fuel flowing through the filter and to the injection pump.

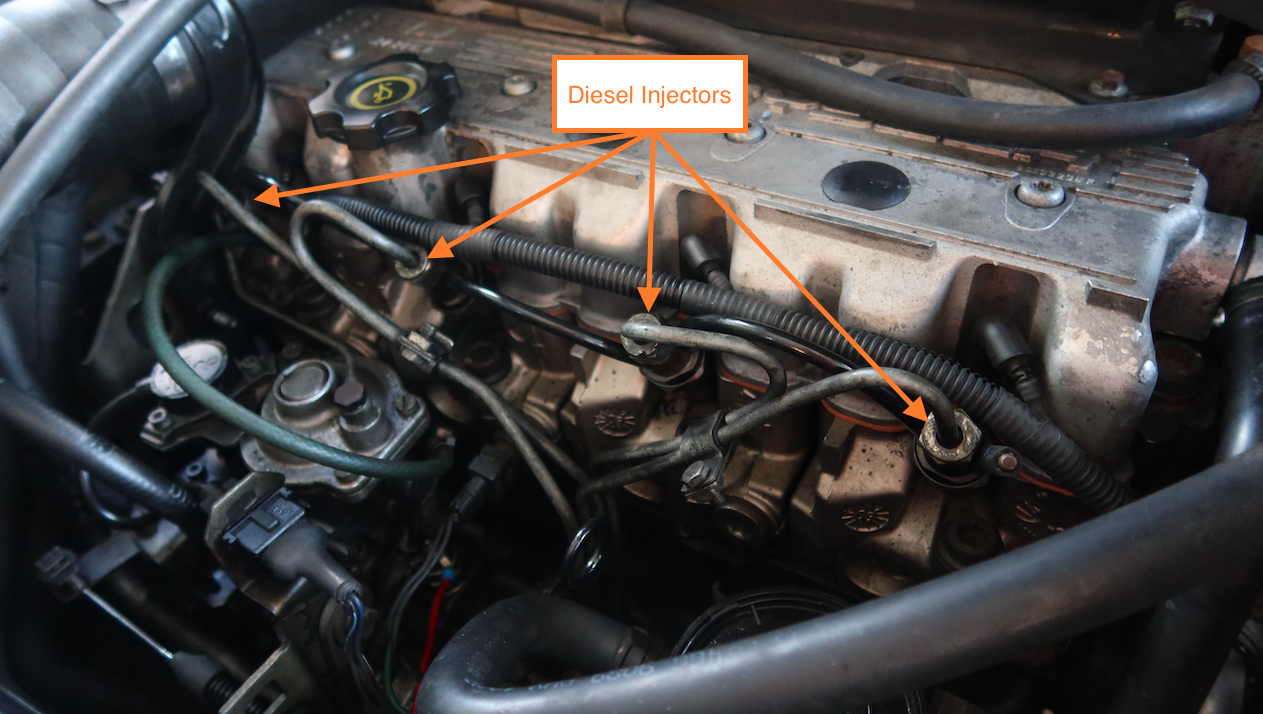

With fuel now reaching the injection pump, I tried cranking the engine over, but it did not fire. Suspecting air between the pump and injectors, Loyal cracked the injectors loose from the cylinder head to allow the pump to displace that air with fuel as I cranked the motor over. In short order, fuel leaked out from the space around the injectors' threads. Now that we knew we had fuel entering the engine, it was only a matter of time before this long-sitting engine fired up for the first time in who knows how long.

When that VM Motori 2.5-liter turbodiesel did awake from its hibernation, the occasion was simply momentous:

There were still a few issues after that initial start, but Loyal expertly addressed them by fiddling with things and then yelling at me in the driver's seat: "Okay, now try cranking it!" In time, he diagnosed a bad fuel shutoff relay, and later discovered that the tiny diesel return hoses between the injectors were badly cracked and leaking. An extremely cool guy named Jacob (who, incidentally, is working with his girlfriend to fully restore a Land Rover Defender 110) in a nearby garage had some extra hose left over, and gave it to me free of charge (this isn't the first time he's volunteered parts to me—again, he's extremely cool. I'll show you his Land Rover sometime later).

Here's a look at those hoses:

Now, with the fuel system bled and a relay and all leaky hoses replaced, the engine springs to life quickly and confidently. And it doesn't seem to leak much, either. So it seems I'll be able to avoid having to tear into the incredibly intricate mechanical fuel pump.

Of course, I had to go on a test drive, because as a long-time wrencher, I've learned that you can't really diagnose all of a car's problems until you've gotten it on the road. (But mostly, I just wanted to drive this amazing, Graz, Austria-built van from Italy).

The initial test-drive revealed a loud clicking noise anytime I had the wheel turned while applying throttle in gear. This is a telltale sign of a bad CV joint. That, and the fact that the clutch and synchros between first and second and second and third seem to work fine, is pretty much the only thing I surmised, as the initial drive—which I enjoyed with four friends—was quite short and slow.

Expect a full review of how this van drives as soon as I get this axle shaft replaced, and feel more comfortable driving at higher speeds around the private lot here near the workshop.

Since getting the van running and driving, I've really just been waiting on the new axles to show up in the mail (I'll be replacing both sides, for good measure). I did throw in a set of sway bar bushings as you can see in the clip above, though I somehow managed to break a bolt on the most rust-free car I've ever worked on. No matter, though, as I've been working on rusty Michigan junkers for the last seven years, so I took care of the problem with a welder in short-order.

I also did an oil change. Afterward, I ran the car for a minute or so and checked the level. It was right where it was supposed to be. Then, the next day, I got the van up to operating temperature, and let it cool down, noticing that the oil level had risen (and that the oil looked quite dark).

Whether getting the new oil up to temp had knocked some sludge off the top of the engine, which had been sitting for a while, I'm not sure. I just hope the higher dipstick reading isn't a product of some kind of fluid leaking into my crankcase. I've got a head gasket leak tester on the way. If it senses CO2 in the cooling system, I'll have a problem.

But I'm not going to worry. Yet.