This Wrenching Genius Installed Lawnmower Engines Into His Military Jeeps

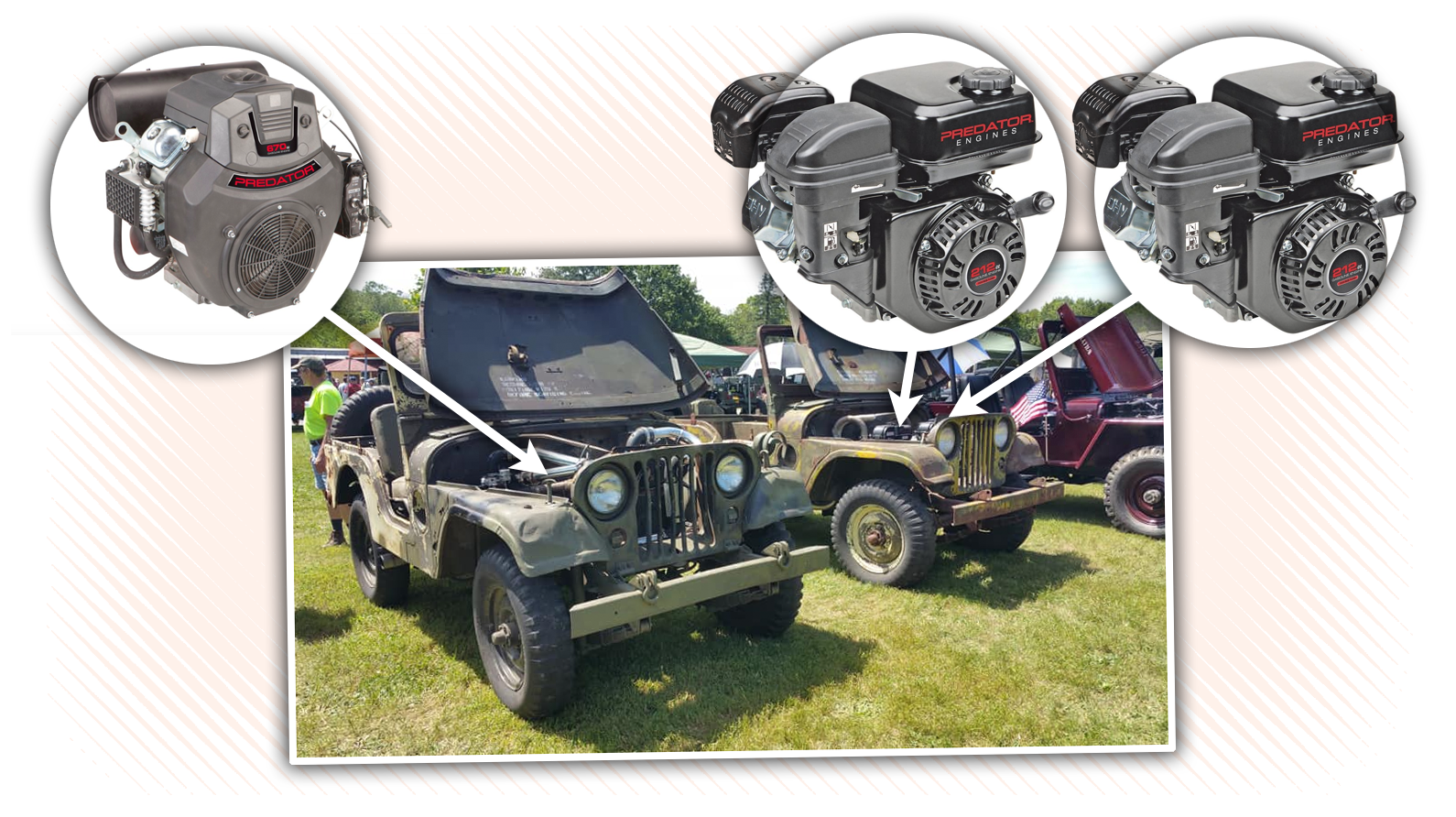

The Willys M38A1s that powered U.S. troops through Korea and Vietnam came from the factory with torquey "Hurricane" 134 cubic-inch four-cylinder engines. But one owner in Pennsylvania swapped his military Jeeps' original engines out for off-the-shelf units meant for mowers and pressure washers, with one vehicle driven by two such engines and the other getting a turbocharger. Check out these amazing contraptions.

I'm a huge fan of the Willys Hurricane motor, as it's derived from the venerable Go-Devil engine found in World War II Jeeps and in civilian Jeeps like my 1948 Willys CJ-2A. But despite my affinity for that hero of a powerplant, I can't help but approve of the ingenious engine swap that a Pennsylvania man named Walter did on his M38A1s (the M38A1 was the basis for the civilian CJ-5, in case you were wondering why this Jeep looks so familiar).

Posted to Facebook by Brett Wagner, the pictures show a yellow and olive-drab Jeep, each of which is now powered by Harbor Freight horizontal-shaft multipurpose engines listed for applications such as mowers, water pumps, and pressure washers. (It's worth noting that many typical store-bought lawnmowers use vertical shaft motors, though a few do use horizontal shaft engines like these).

But despite both Jeeps getting their forward thrust from small off-the-shelf engines, the vehicles are actually quite different under-hood.

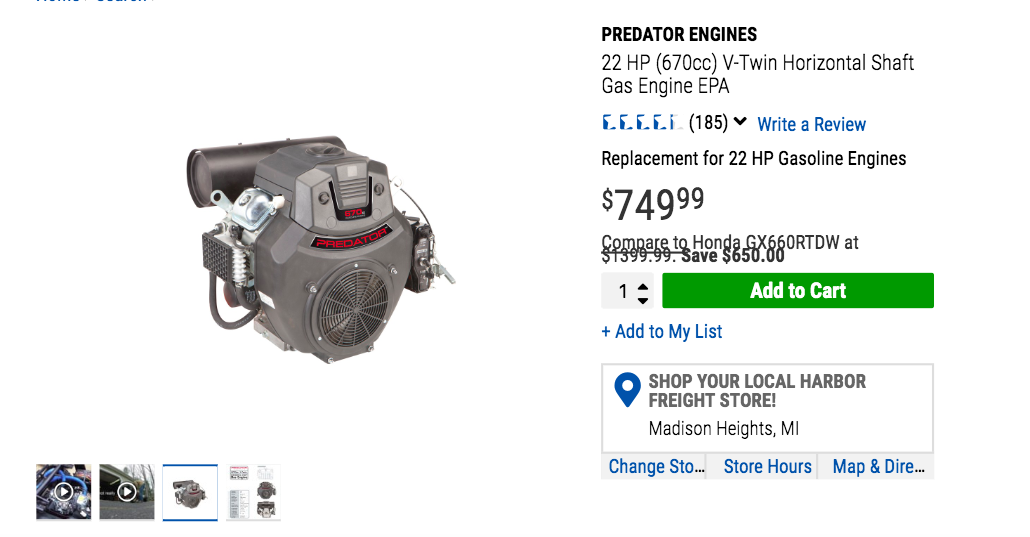

The olive-drab one utilizes a horizontal-shaft 670cc V-twin Harbor Freight "Predator" engine, which—as you can see below—can be purchased for $749.99.

The engine has been mounted onto some sort of platform, which is mounted to the frame. The 670cc unit sends power from its output shaft via two belts to an intermediate jackshaft, which then transfers power via two other belts to pulleys on the input shaft of the original T-90 three-speed manual transmission.

There is no conventional clutch, but the engine's output shaft contains a centrifugal one that only engages the transmission above a certain engine speed.

What's especially awesome about this setup is that the 22 horsepower 670c engine has a grease-lubricated turbocharger hooked up to it. Here's a closer look at that turbo, which is mounted to the fender and firewall:

The exhaust routing looks fairly straightforward, with one pipe teeing into the other before the hot gases spool up the turbo turbine. Clean air enters the turbo compressor after flowing through a filter in the grille and then through a long intake pipe. After being compressed, the air exits the turbo, routes down into what looks like a finned cooling tube (see below), and then up into the intake at the top of the motor.

You can see the engine run in the video below, though you'll notice that the intercooler pipe hadn't yet been installed:

The video below includes an interview with the owner, as well as footage of him driving the homebrew machine:

At the Jeep show he attended, Facebooker Brett Wagner also took some photos of the yellow M38A1, which he says was assembled by the same owner as the turbo V-twin model.

Instead of a 670cc twin, the yellow Jeep makes do with two horizontal shaft 212cc single-cylinder motors like the one that a young man installed into the Dodge Ram and that we wrote about back in May. These 6.5 horsepower engines sell at Harbor Freight for $119.99, as shown below.

Here's a look at the two-motor setup in the yellow M38A1:

If I'm entirely honest, I'm not really sure how the two engines work together to send power to the transmission' input shaft. If I had to guess, I'd say each motor's clutched output shaft likely sends power via pulleys and belts to a common jackshaft, which—with pulleys on its other end—then sends power to the transmission's input shaft pulleys.

I bet finding a running F-Head motor would have cost less time and money than building these "Predator" engine-swapped military Jeeps, so I have to give the owner credit for the creativity and hard work that went into building these unique, fascinating off-roaders.