The Absurd Reason Why This Jeep's Door Won't Close

Cars fail in a variety of ways, and that's normal. But this failure is very much not.

My base-model 1993 Jeep Grand Cherokee five-speed's door is sagging, and while that may not seem like a big deal, the reason why this is happening is a bit absurd. Here's a look at one of the most pathetic automotive failures I've ever seen.

A saggy door is usually caused by a worn out hinge pin. A few bucks and an hour or two are usually all you need to get the closure's latch lined up beautifully with the B-pillar's striker. Unfortunately, my beautiful rust-free red manual Jeep Grand Cherokee — which my colleague harrowingly drove to my Michigan abode from Reno — isn't going to recover that easily.

Its driver's door sags a lot, to the point where closing that hatch in a nonchalant way leads to a no-latch condition, which — as I found out yesterday — can lead to a "door flying open while driving" condition. Three out of four physicians don't recommend this condition.

The antidote to my Jeep's door's ailment is involved. Simply a new pin won't suffice, for the door is literally splitting apart at the seam:

I've never seen anything like this. Opening the door literally forces the door's outer and inner panels to split at their hemming. Here are some still images of the door separation, which stretches over a foot in length:

The result of this failure is a door that won't close unless you lift it. Just look at the damage the latch area has taken from hitting the striker:

To figure out what's going on, let's talk about how doors are made. As you might have guessed, they start out as sheetmetal, with two major pieces — the inner and outer panels — stamped using big metal dies and hydraulic presses. The inner panel is made up of multiple pieces that are spot welded together, while the outer really is just one piece.

With steel reinforcement beams, sound-deadening material and more between them, the inner and outer panels are joined with adhesive and with a hemming.

To learn more about hemmings, I read the Pocket Guide On Hem Flange Bonding. It's a small book written by Atlas Copco, a Swedish machinery/tool manufacturer, and it's all about hem flanges.

At this point, your mouse is probably hovering dangerously close to your browser's "back" button. Depending upon how alarmed you are, you may even be on the verge of violently and repeatedly slamming the control-alt-delete buttons or even yanking out your laptop's battery. But just relax; we're all going be fine spending a few moments of our day reading about hem flanges. Yes, hem flanges.

Here's a basic intro to the hem flange and the adhesive that holds the outer and inner door panels together, via the aforementioned publication:

The hem flange describes a mechanical joint design which is used for joining inner and outer closure panels, as in metal doors, hoods, bonnets, or liftgates. To increase crash resistance the gap between the hemmed panels is filled with high-strength adhesive which also prevents corrosion.

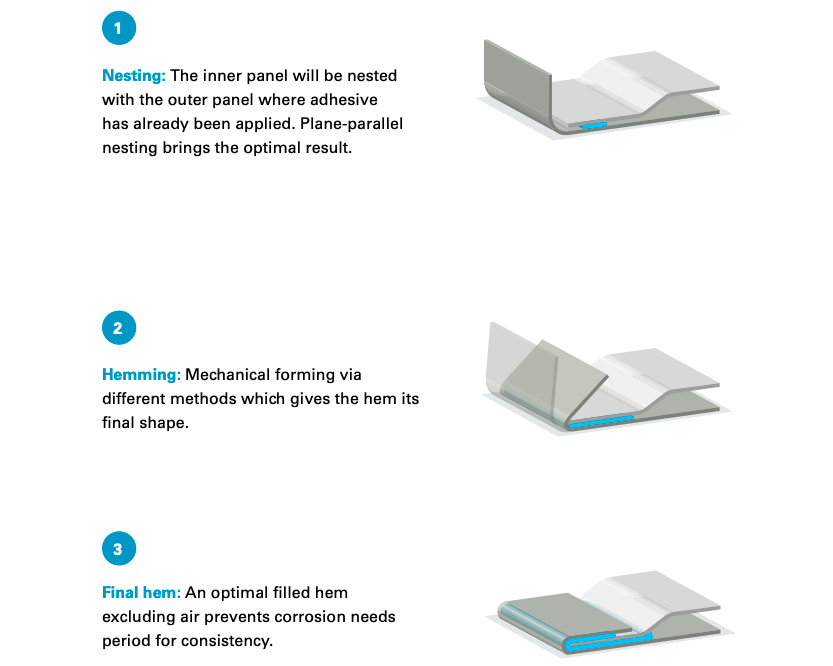

This is where things get exciting. Check out the process for creating a hem flange. You basically set the inner door panel up against the outer panel, with adhesive between them. Then you fold the outer over the inner, with adhesive between that folded-over outer panel and the top of the inner:

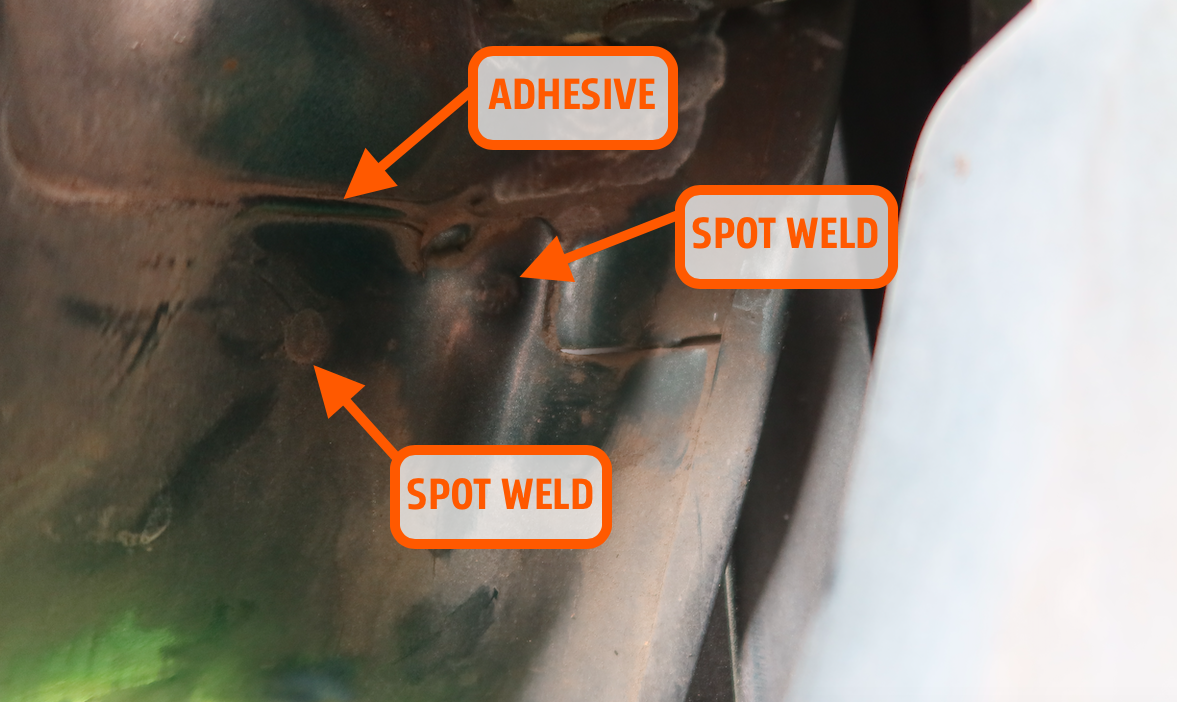

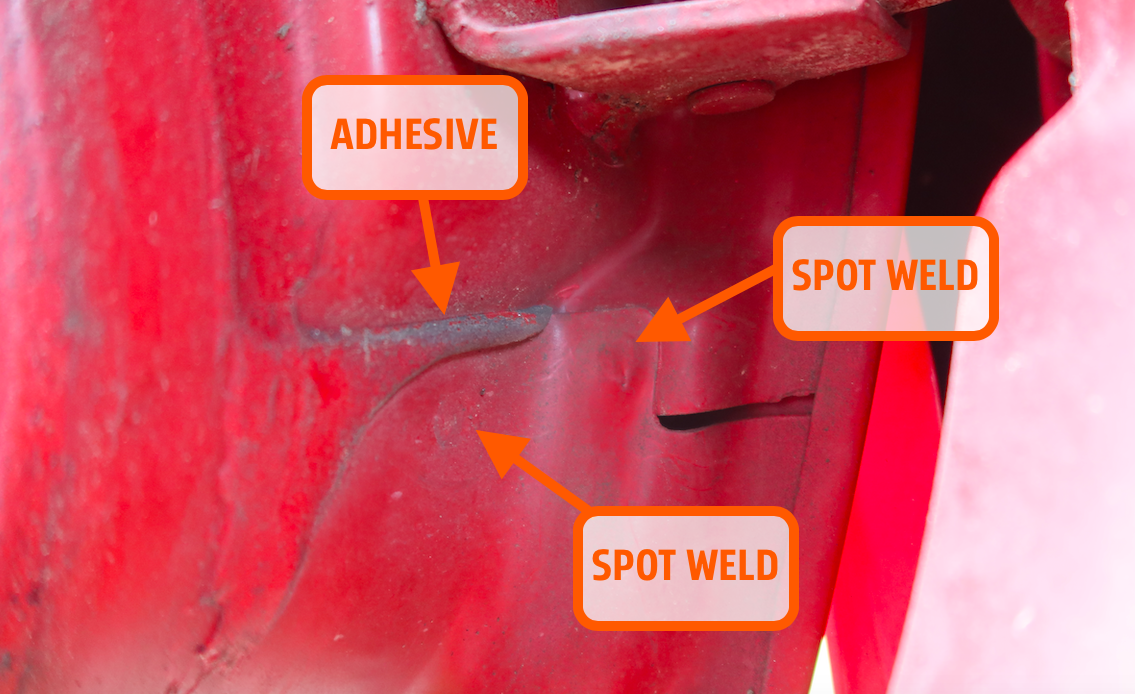

You can see some residual adhesive on my door:

Why not just weld the two doors together, you might wonder? Well, if I had to guess, this is cheaper and easier, and also, it looks better. Here's what that masterpiece, Pocket Guide On Hem Flange Bonding, has to say:

Hemming parts hides the cutting edges of the metal sheets. This helps both to prevent injuries and to improve the external appearance. While the adhesive between the inner and outer sheet fulfills a structural function, it also helps to prevent corrosion.

Mechanical joining techniques as well as spot-welding are not suitable for the hem flange production, since they would leave unwanted visible spots on the joints. This is why adhesive bonding plays an extremely important role in the BIW production of all closure parts.

There are multiple ways to create a hem; one can use a press or a roller to fold the outer part. I won't get into that, but what I will do is guess what I think caused this ridiculous failure in the first place.

My failed door is on a September, 1992 build (1993 model year — the first Jeep Grand Cherokee ever). The Jeep Grand Cherokee came out in 1992, and it was built in the then-brand-new Jefferson North Assembly Plant. It wouldn't be surprising to learn that early production cars still had some kinks to iron out, and that that's what we're seeing here.

My theory is that my 1993 Jeep's spot welding quality just wasn't up to snuff. If you look at my 1994 Jeep Grand Cherokee (built in May, 1994), you'll see that its door is still intact. Notice the nice spot welds holding the two pieces that make up the inner panel together:

I also have a March, 1994 Jeep Grand Cherokee, whose inner panel welds look great:

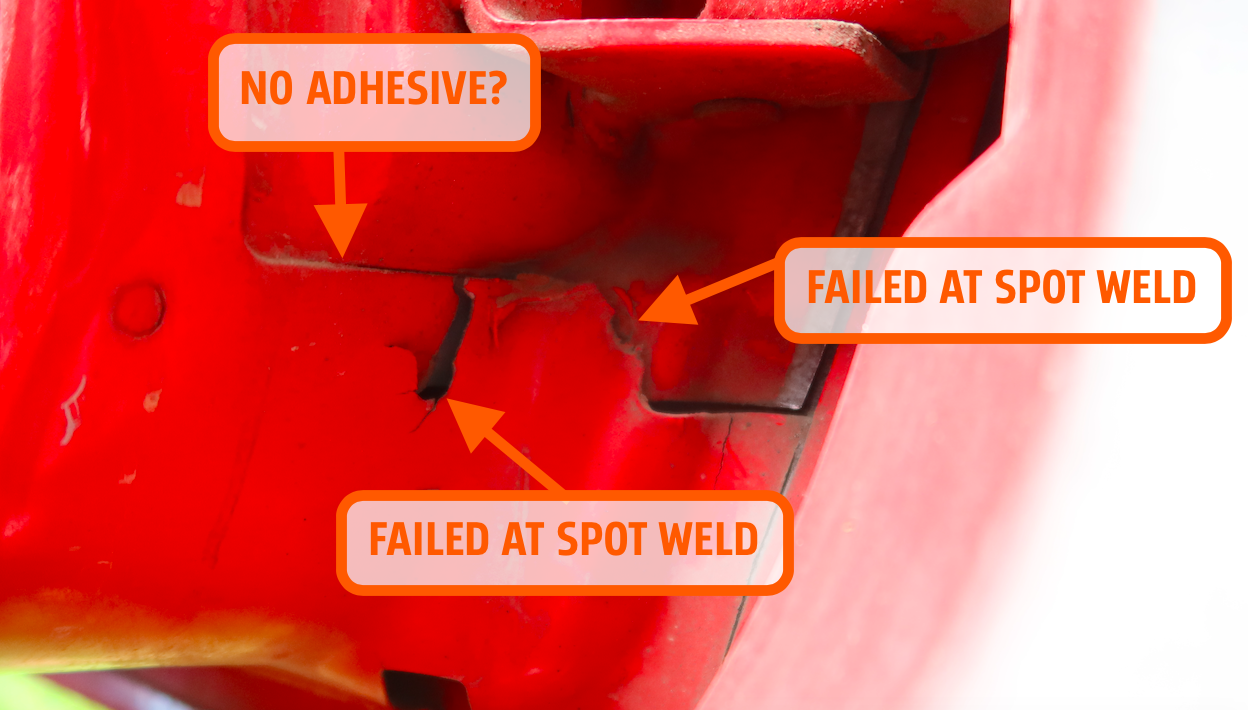

Now here's my failed 1993 (again, built in September, 1992). Note how the metal failed around the two spot welds, and how there doesn't appear to be as much adhesive joining the two parts making up the inner panel:

My guess is that the spot weld failed as the result of a rather violent door-opening incident. What we're looking at, I think, is called the "nugget pullout" failure mode of a spot weld. This basically means the spot weld — which you can think of as a really stiff circle surrounded by ductile metal — failed around its circumference.

Here's a quote about pullout from Failure mode of spot welds: interfacial versus pullout written by someone named Y.J. Chao in the 2003 publication Science and Technology of Welding and Joining Volume 8:

The hardness of the nugget of a spot weld in sheet steels used in the automotive industry is typically two or three times that of the base metal. Consequently, the nugget functions mechanically as a rigid button embedded in a ductile metal sheet. The pullout failure of a spot weld in a cross tension sample is thus predominantly plastic shear or plastic collapse around the circumference of the weld nugget in the heat affected zone.

With the two welds having failed, the inner door panel lacks rigidity, and has a tendency to want to pull out of the outer door panel's hem flange under load (like when the door bounces off of its stop when fully opened).

Perhaps Jeep changed its spot welding process later in the production run to ensure that such a failure no longer occurs, because my green 1994 Jeep shown above has 265,000 miles on the clock, while the failed 1993 has only 125,000. Clearly, the 1994 has had more door-opening events, so I'd be inclined to say that, if the red 1993 Jeep's door failed in fatigue, then clearly Jeep changed something up in the manufacturing process to prevent such a failure on future models.

I reached out to seasoned manufacturing/body engineer Ritesh Sharma, who admittedly hasn't dealt with closures in a while, but who was still willing to talk some things through with me. Here's what he said about a potential cause of my door's failure:

This could possibly be from an immature production process in early production due to newness: Design of the door construction changed fractionally before mass production release which could have impacted the spot weld strength if the metal sheets have got a larger gap or have a high stress concentration. That or the actual welding process may not have been fully matured. This could also be variation in production as well, perhaps the individual skins have got variation in thickness. With it being the early 90s, that process may not have been automated at the time as well so there could have been human error.

Anyway, this was all just a long-winded way of me showing off what I consider one of the most pathetic failures I've ever seen. I'm not sure I've quite discovered the root cause behind why it happened, because even though it looks like a spot weld failure, you'll notice that the door itself — even in areas a short distance from the two failed welds — has undergone brittle cracking.

It's possible that the weld quality was fine, but that someone opened the door much, much too hard (harder than my other Jeeps' driver's doors have ever been opened), cracking the sheetmetal and pulling out the spot welds.

For now, it remains a mystery. How I'm going to fix this without ruining the paint on the outside of the door, I'm not sure.