My Free Jeep Grand Wagoneer Drives But Nearly Started A Demolition Derby In My Backyard

Oh boy is today's wrenching tale a classic DT blunder. My Jeep Grand Wagoneer, which I obtained for free from a generous reader named Tammy, has been giving me hell, with its brakes failing, and its motor refusing to consistently start. Over the past few days, I've mended those problems (sort of), and gotten the Jeep to drive under its own power. Then things nearly went off the rails.

The Grand Wagoneer didn't run when I got it back in June, which isn't surprising given that it cost me literally no dollars. As far as I know, the Woodie hasn't run for the better part of a decade. When I got it home, I changed its oil and fuel pump (the rubber diaphragm inside of them tends to fail), slapped in a new battery, and threw in a new ignition cylinder since I didn't have the old key.

Unfortunately, the damn thing still wouldn't start with the key. For some reason, the ignition switch doesn't activate the starter solenoid, so to get the Jeep running, I have to use a jumper wire between the battery and one side of the starter solenoid to get power to the ignition system, and then I have to momentarily touch the positive battery cable to the far side of the solenoid to crank the starter.

This worked for a while. In fact, after starting the Jeep for the first time in years, I discovered a mouse nest in my exhaust system:

This was way back in October, and it's a miracle that someone didn't call the cops after I created a literal cloud in my yard by burning off all the automatic transmission fluid I'd poured into the cylinders (this was to ensure the piston rings wouldn't gouge the cylinder walls, since the Jeep hadn't run in a while).

Despite having gotten the Jeep running last fall, as soon as I went to drive the thing, my brake pedal fell to the floor and an entire master cylinder worth of hydraulic fluid poured onto the grass. My brake lines were rusted out.

Fast forward to March and I'd purchased some new front brake lines and prepared to install them:

,

Buying pre-formed lines was the easy way to replace my rotted-out lines and it only cost me $70. Still, the job wasn't that easy, as snaking those hard lines through tight spots between the frame and steering box without kinking them was tricky. Plus, trying to spin the lines into the combination valve without cross-threading something was also tough, and required me to unbolt the valve from the frame.

But in time, I got the new steel tubes installed. Behold:

In October, as soon as I got the engine running, the brakes went out. Now, as soon as I've fixed the brakes, the engine stopped starting. I spent a while trying to diagnose the issue. I pulled out a spark plug wire, popped on a spare spark plug, grounded the plug against the engine while cranking the motor (again, using the positive battery cable against the starter solenoid) and I did see spark.

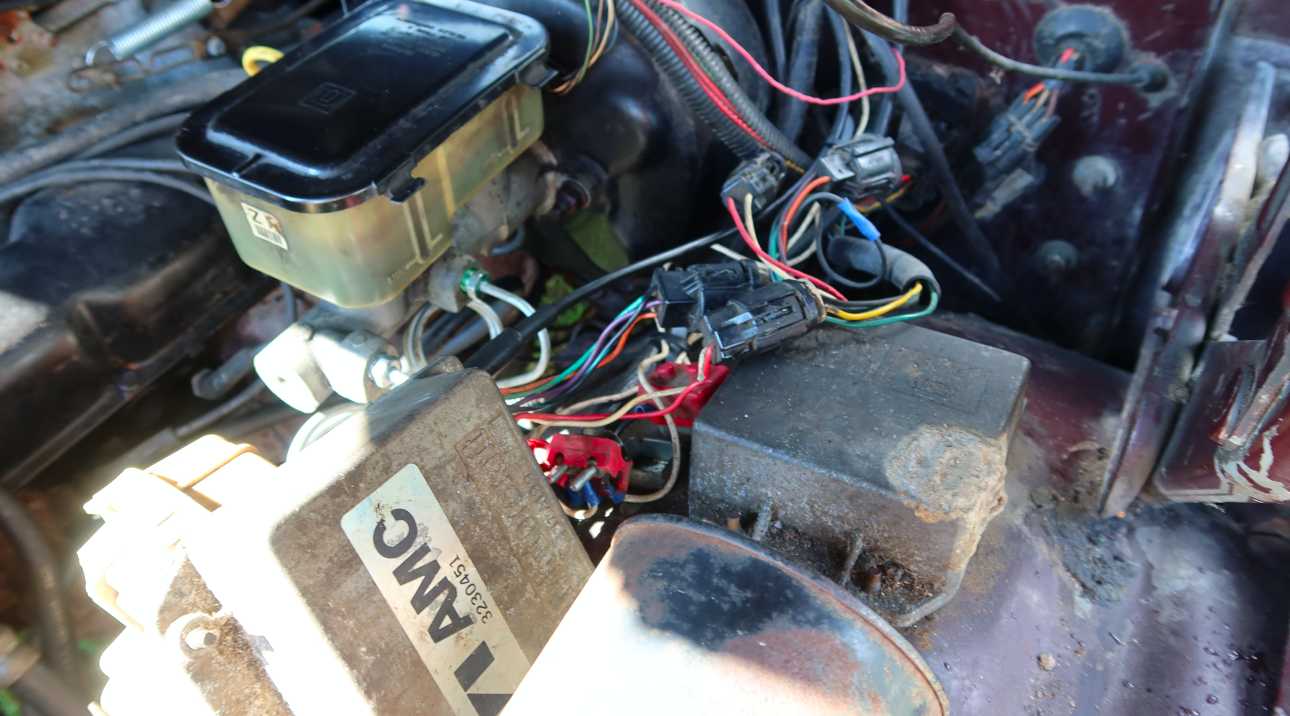

If I had spark, fuel (I was using starting fluid) and air, why wasn't the engine running? After taking a break for a few days, I got back to the Jeep, and ultimately figured out that the problem was the ignition module. I have a few spares sitting around the house, so I plugged one in:

With that hooked up, the Jeep ran for a few moments on starting fluid. Strangely, I saw no fuel going through the clear fuel filter despite having replaced the pump. Even after I poured a five-gallon Jerry can worth of gas into the Grand Wagoneer's tank, something was stopping the fuel pump from sucking the go-juice into the motor.

So I yanked the rubber hose leading from the pump to the steel fuel line and noticed it was old and cracked. I attached a new one to the fuel hard line and blew on the other end of the hose, forcing any rust or crud in the lines back into the tank. I then hooked the hose to my fuel pump, cranked the motor, and noticed fuel in the filter:

Now the engine runs off of its own fuel supply and no longer requires me to spray copious volumes of starting fluid down the carb throat. Just listen to this beauty idle:

With the Jeep now running on its own and after having bled the front brakes, I yanked the column-mounted automatic shifter into drive and gave the Jeep some gas. The AMC V8 roared as the revs climbed, and the Jeep—with two flat tires—dug its way out of the mud hole its 4,500 pound weight had created in my soft backyard.

I began driving toward the rest of my fleet—specifically my "dream" 1991 Jeep Cherokee five-speed and my much-less-dreamy totaled 2003 Kia Rio. So I let off the gas. But the engine's revs wouldn't drop. I stomped my right foot on the brake pedal, but with only the front brakes working and the engine revving hard the Jeep kept progressing, as if on an evil crusade to mangle the rest of my fleet in what would, at least from the outside, look like an absurd demolition derby of shitboxes in quaint and quiet Troy, Michigan.

Luckily, I had the wherewithal to quickly force the shifter into Neutral and turn the ignition off well before anything became an issue. Then I fired the Jeep back up—again, I'm doing this from under-hood, since the ignition switch in the steering column won't activate the starter solenoid—and the Jeep screamed. Revs climbed well beyond what I felt comfortable with, so I disconnected the battery cable.

The Jeep kept running!

This surprised me. The Jeep was running with no battery connected! (This won't work at idle, but at high RPM, it apparently does work on older cars). I ran into the cabin and turned the key to the "off" position, tranquilizing the mighty AMC 360.

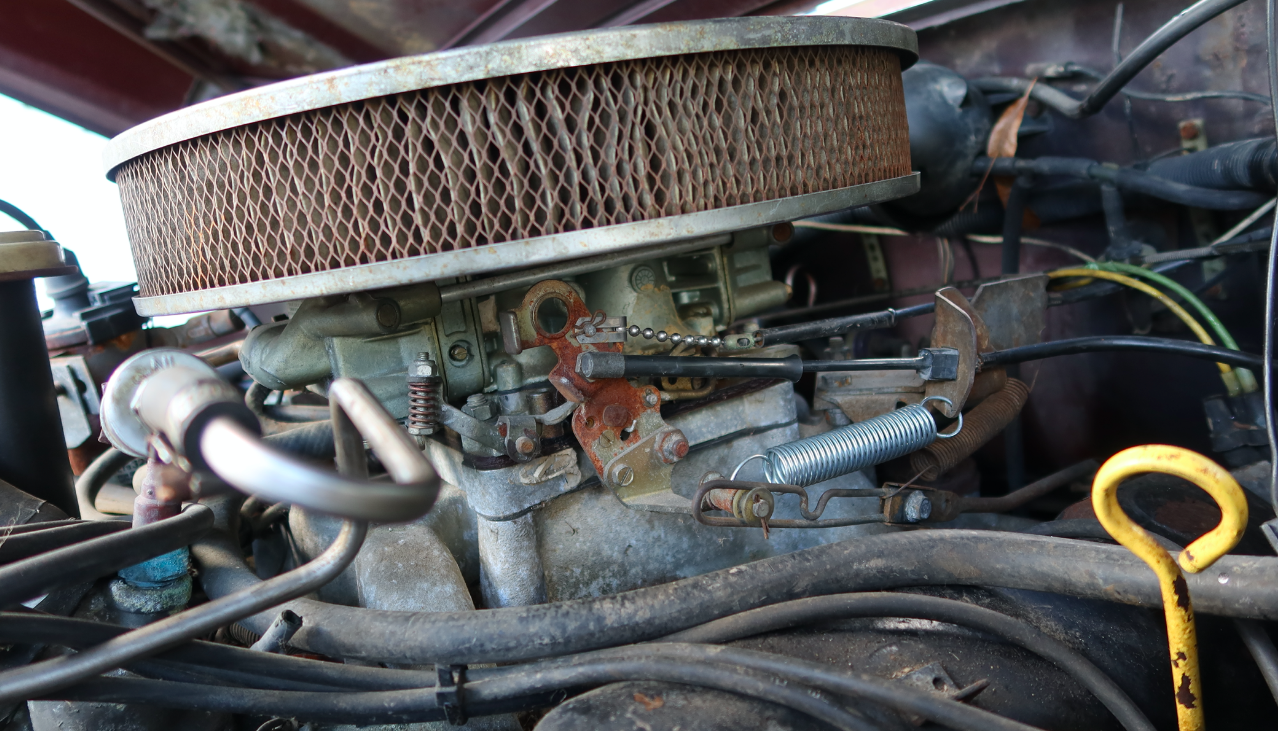

I later learned that the throttle return spring (which I had replaced, since the old one had failed—its spring constant was essentially zero; I could stretch it with no effort whatsoever) had fallen off, causing the throttle to remain open even after I let off the gas pedal.

It's amazing how something as simple and small as a throttle return spring is the difference between a car that idles beautifully and slows down when you let off the gas and a potential 4,500 pound runaway car. Lesson here is: Pay attention to your damn throttle return springs.

The Jeep will soon be up for sale. It runs (though I think the fan is banging into the shroud, and the flex plate bolts are loose—because there are strange noises happening when that motor is running), stops (again, just the front brakes), and its interior has been mostly cleaned out. It's a great base for a restoration, I think.

I just want it out of my yard before it tries to attack another Jeep.