Learn The Fascinating Mechanics Of How A Gas Pump Nozzle Knows When To Stop

The modern world runs on this clever use of fluid dynamics.

It's amazing how, all around us, simple physics are used in complex ways we really take for granted, especially when it comes to cars. A popular science YouTuber and author came up with a really engaging way of teaching a little bit about the fluid dynamics of a gas pump. It turns out, the whole contraption is a bit genius.

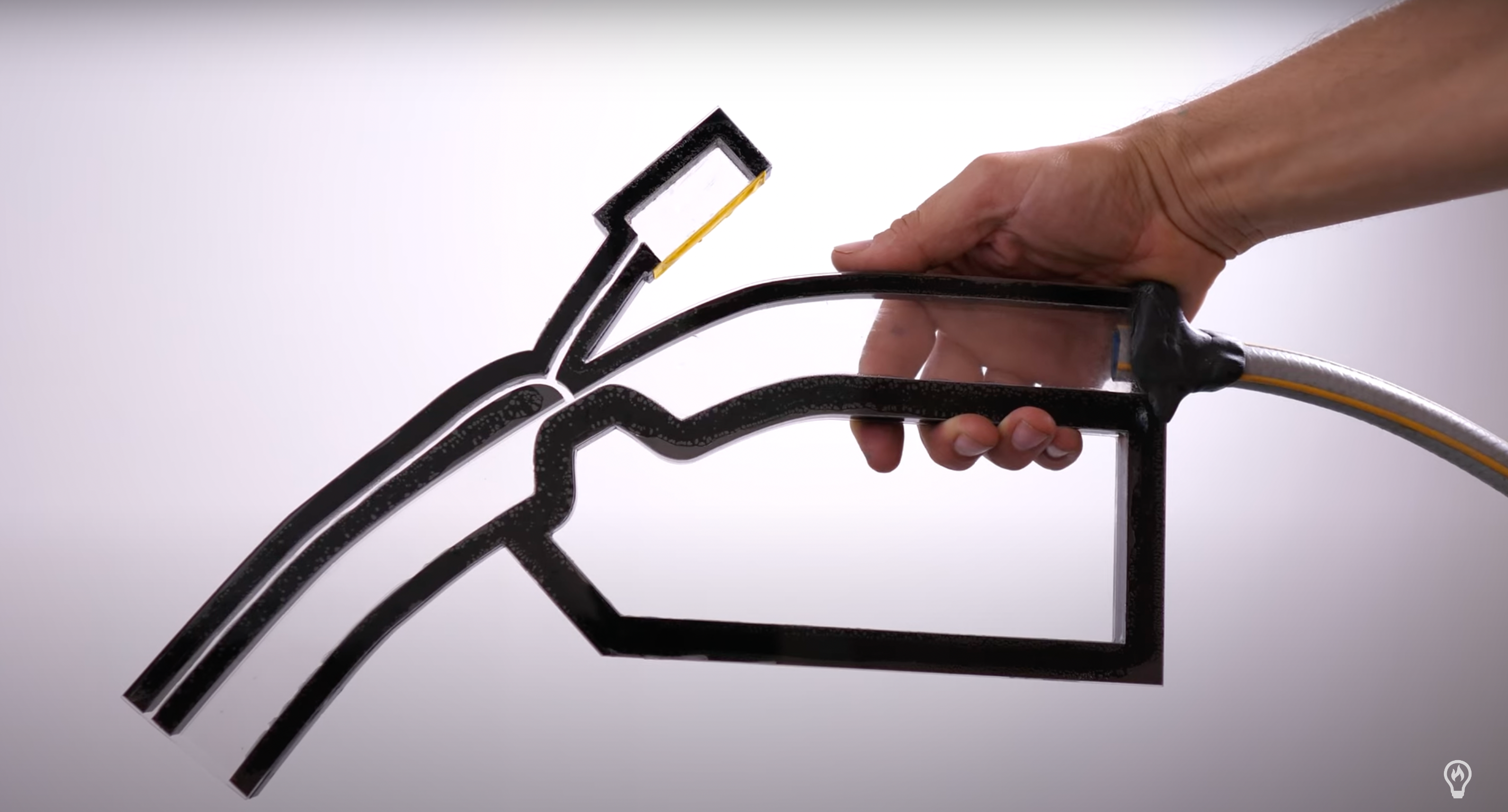

It's a subject we've covered before, but this video in particular did a great job of visually explaining things. Steve Mould may look like the most tired man in Britain, but he has a fantastic way of describing the complex interplay of physics. He uses neat cutaway models and a split fuel pump to illustrate how it all works. I am an affirmed owner of a liberal arts degree, and even my cream cheese-soft brain could follow along.

The entire behavior of the fuel pump is based on simple fluid dynamics and the exchange of pressure which causes the gas to flow as well as stop when the gas reaches the top of the tank. I could try and parse it for you here, but it's probably safer if you just watch the video and Mould's engaging visual examples of the concepts involved.

What I am qualified to tell you is that the gas pump is credited to the incredibly named Sylvanus Freelove Bowser who sold his first one to a grocery store in Indiana in 1885. Initially meant to pump kerosene, Bowser soon realized the pump would fit gasoline for the latest invention; the automobile. Here's what the Zimmerman Automobile Driving museum as to say about the first pumps, which did not use physics to stop the flow of fuel, but rather the knack of the clerks:

Though his pump was not originally designed to serve automobiles, by the 1890s, Bowser noticed his invention of the kerosene pump could accommodate the horseless carriages. He added a hose to his pump, and eventually a nozzle. Clerks would count the number of cranks (pumps) they made with the handle to determine how many gallons had been delivered into a customer's tank (one crank would equal one gallon).

Generally, the clerk would also put an ear to the automobile's tank to listen for the sound of gas filling. Some clerks looked down the hole to see the height of the gas level, determining when the customer's tank was full. These methods proved to be both inefficient and dangerous.

By 1910, a clockface (to measure the amount of gasoline being pumped) was added to newly manufactured pumps. The retailers who resisted the investment of a new pump outfitted their crude, older pumps with accessorized clockfaces. The demand for an even more precise way to measure what was being purchased led to the design of a visible gas pump.

By the 1920s, the pressure valve style seen in the video became commonplace, along with electric gas pumps, though many pumps retained "sight glasses" which allowed drivers to see the quality of the gas and how much was being pumped. These gradually faded aways as consumer confidence in gas stations increased.