I Helped Reassemble A Stripped-Down 2020 Chevy Corvette C8. What I Saw Was Beautiful

If you want to see the 2020 Chevy Corvette C8 up close — like really, really close— then today is your day. A few weekends ago, I had a chance to help reassemble a C8 that had been torn into hundreds of pieces; the images and video I snagged of the car's hardware nearly made me faint. Yes, it's that beautiful.

When it comes to car tech geekery, cutaways and CAD images are what dreams are made of. But nothing compares to actually having a full car at your disposal, ready to be tinkered with and admired from every angle. When that car is something as exciting as a Corvette C8, you may need to grab a paper bag to control your breathing; I know I sure did.

The car belongs to Darko Stojanovski, the owner of Pacific Motors, an exotic car salvage operation based in Detroit. Working in a retired steelworks a few weekends ago, Darko and his friends began reassembling a 2020 Chevy Corvette C8 that some enterprising gentlemen had apparently hoped to use as the basis for some kind of custom supercar.

Darko told me that by the time those ambitious men realized that building a bespoke machine on the C8's platform would be more trouble than it was worth, they'd already torn the 'Vette into a few hundred pieces. So the defeated men called up Darko, who decided to buy the enormous Lego project and complete it with some buddies, all of whom were undoubtedly intrigued by the prospect of seeing a vehicle this new in such a state of chaos. Luckily, I was invited to join in the fun.

I'll admit that I barely did a thing, as I was mostly focused on staring at hardware and keeping six feet away from everyone. But even though I threaded in no more than a bolt or two, I did get to closely study the numerous systems and subsystems of the first midengine Corvette to enter production. This isn't an opportunity everyone gets — at least, not this soon after launch. So of course, I just had to show you, since I know many of you readers share my affinity for nerdy tech.

I'll keep this writeup brief because I just spent what feels like a million years editing the video above, and my editors will kill me if I delay this story any longer. (This is true. —Ed.) But should you be unable to activate your cathode ray tube monitor to watch the motion picture, take a look at the static shots I managed to grab.

On entering the enormous Detroit facility, I spotted the Corvette perched on a hydraulic lift, its body panels, doors and entire powertrain strewn about. Seen prominently at the nose were the two outboard heat exchangers, there to chill coolant and ensure that the engine and transmission — both of which feature coolant-to-oil stack-style heat exchangers—remain at optimal temperatures. There's also an air-conditioning condenser (shown below) that sends refrigerant to the compressor on the engine's accessory drive.

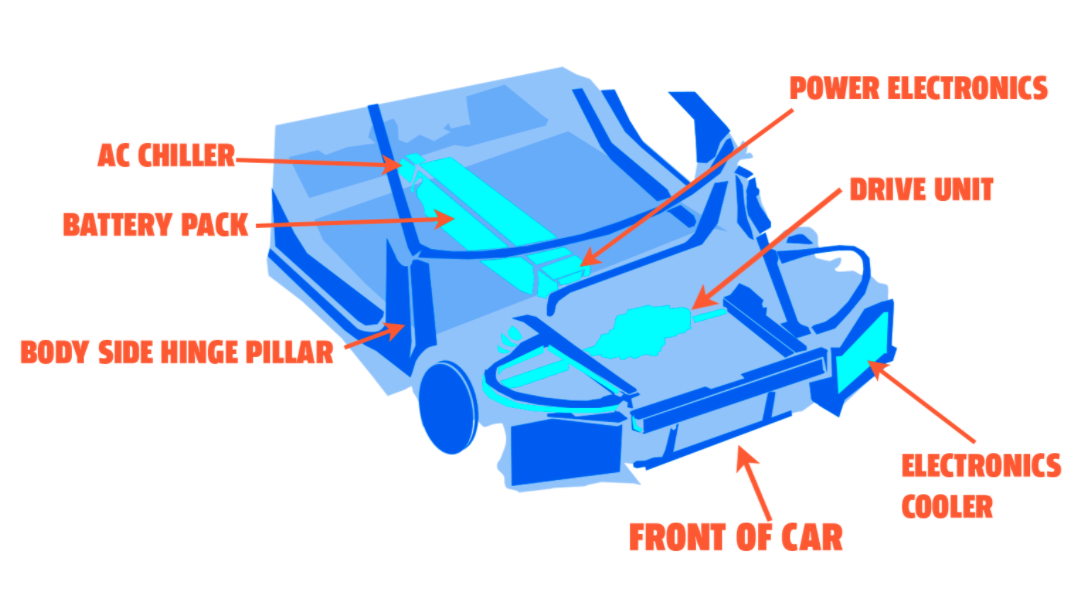

Below the vehicle I saw a tunnel that houses the plumbing for the refrigerant and liquid coolant. Obviously, the tunnel is oversize for just these occupants, suggesting that the space is likely being reserved for something else in a different Corvette application.

That "something else" is almost certainly a lithium ion battery pack, which will feed current to an electric motor at the front axle, per our story on the future hybrid 'Vette. Here's a diagram my coworker Jason Torchinsky made for that story, which Bozi Tatarevic wrote based on official GM documents:

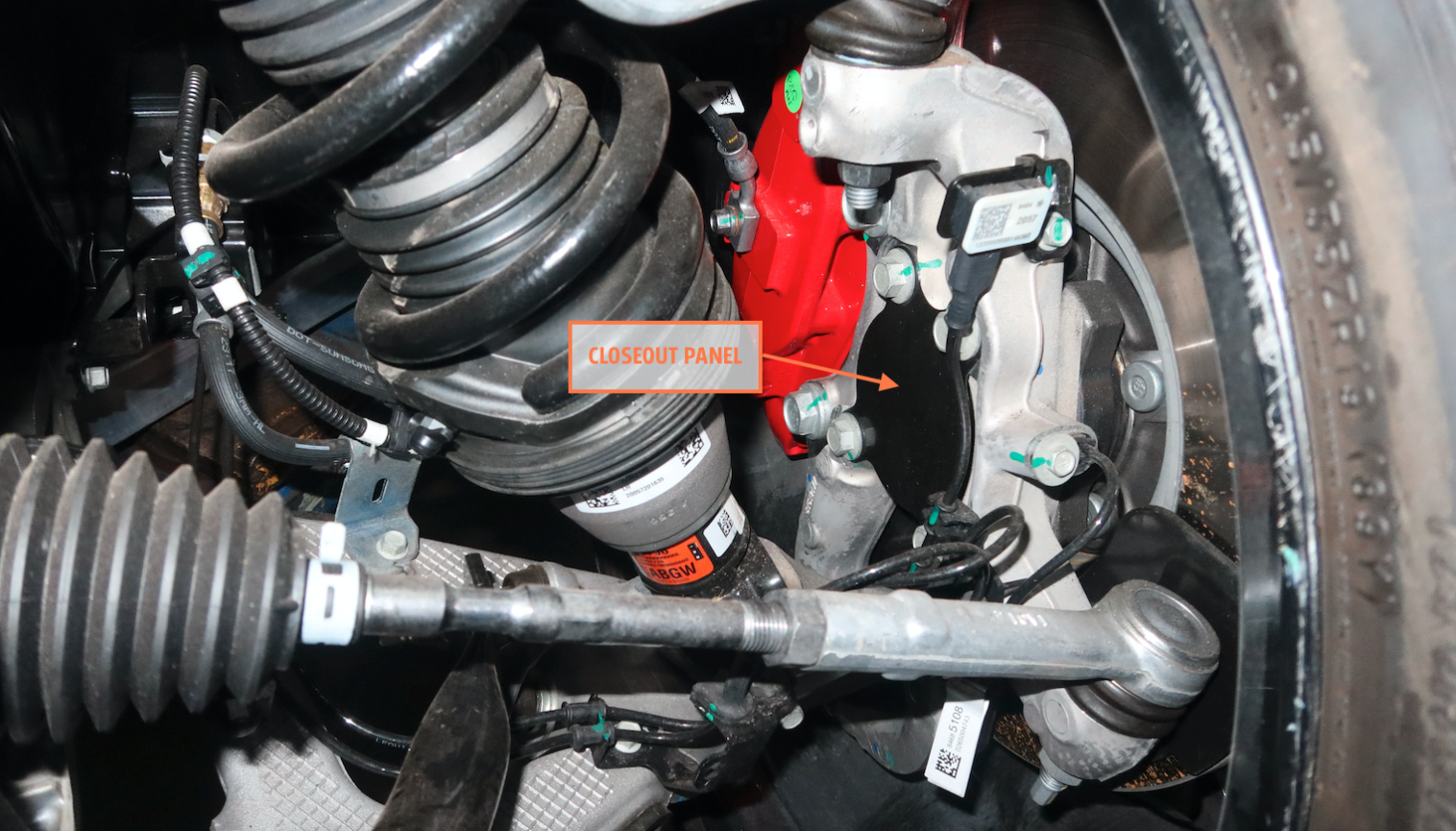

As Bozi noted, the Corvette's front knuckles are each outfitted with a cover where an axle shaft might pass through to the splined hub of a future all-wheel drive hybrid Corvette:

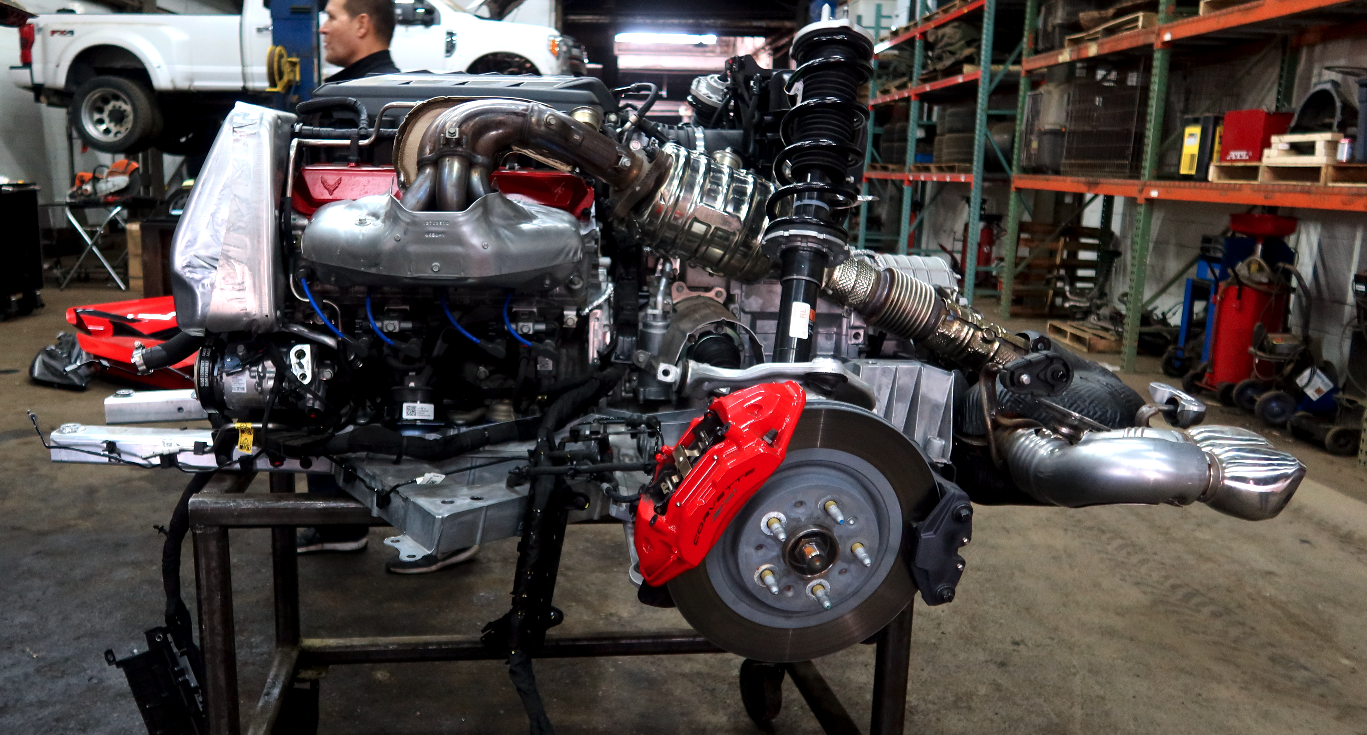

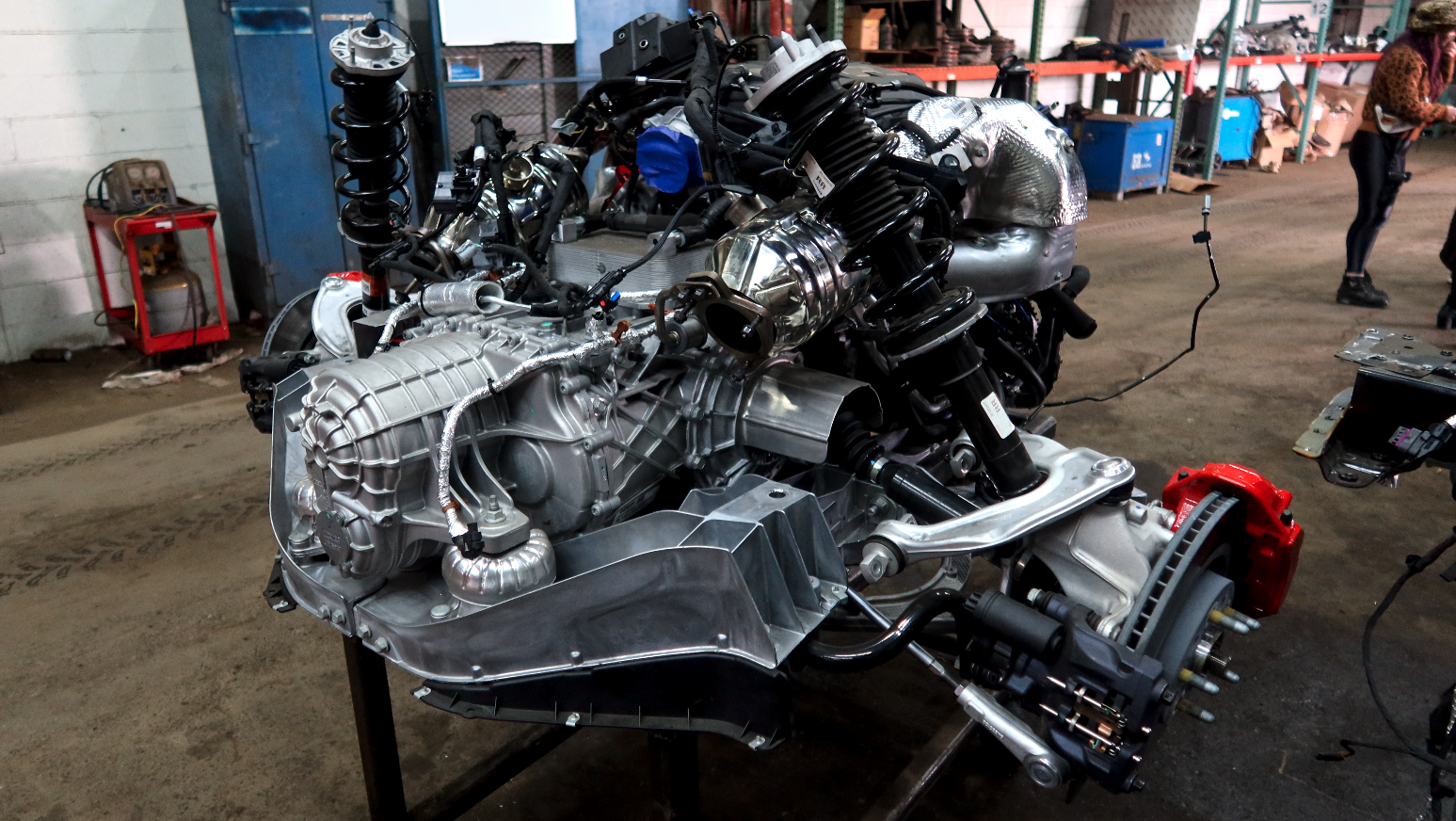

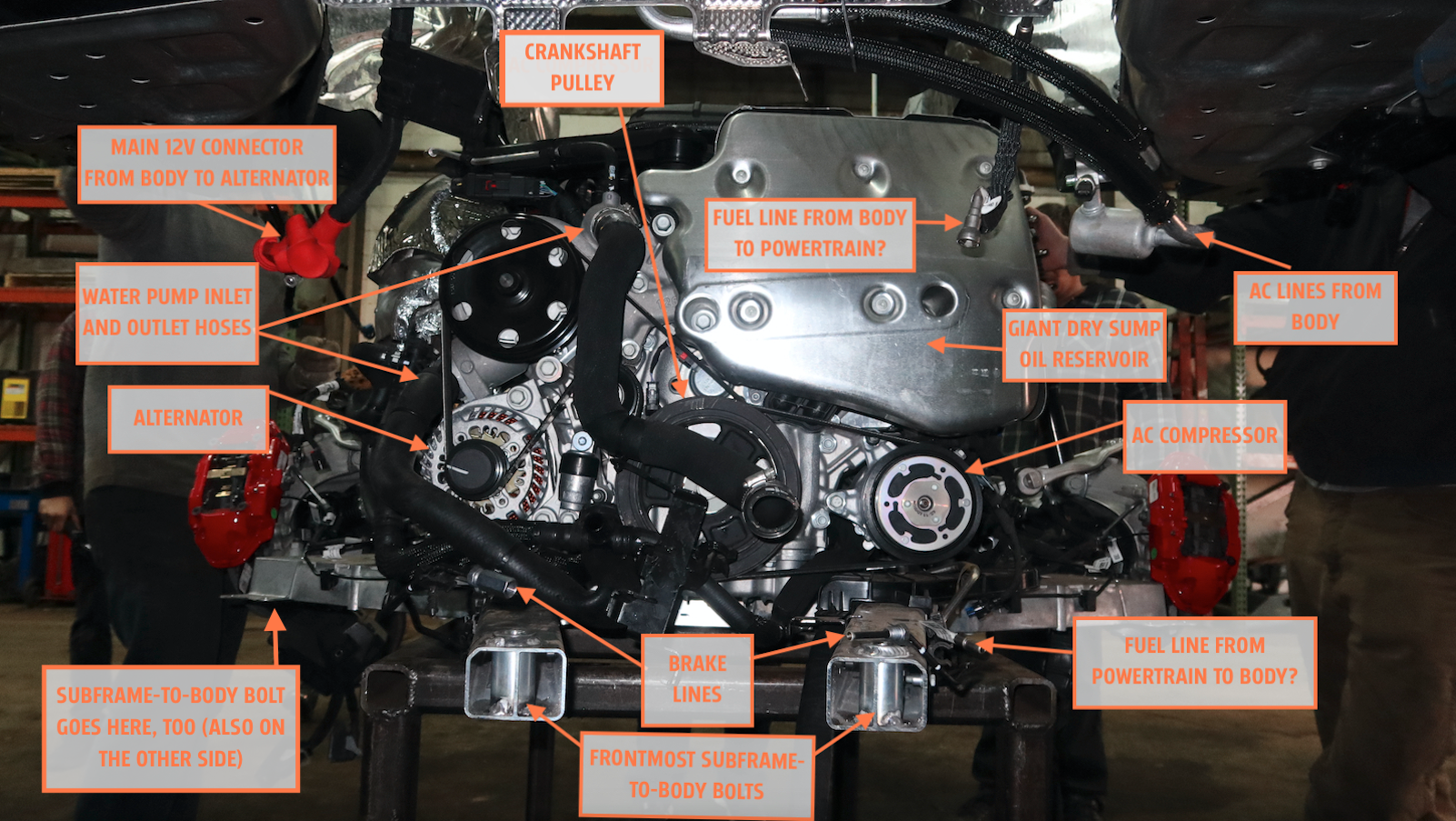

Sitting on a cart behind the Corvette was the full powertrain and drivetrain mounted to a cast-aluminum subframe. The sight of the 495 horsepower 6.2-liter small block V8 and eight-speed dual-clutch transmission, all bolted to a subframe, was simply breathtaking:

Here are some photos of the spark plug locations on the driver's side bank. You'll notice that the ignition coils are bolted to the engine block. It looks fairly elegant:

That big silver tank on the left side of the images above is the dry sump lubrication reservoir, in case you were curious.

Under the direction of a gentleman quite familiar with Corvette C8 assembly, the team of wrenchers rolled the rear cradle under the car's chassis:

The decking (an industry term used to represent the marriage of the powertrain with the body) procedure was fairly straightforward. Using the lift, Darko lowered the body down onto the rear subframe. Two wrenchers guided the rear coilovers into the car's towers and then zipped the nuts down with an electric impact wrench:

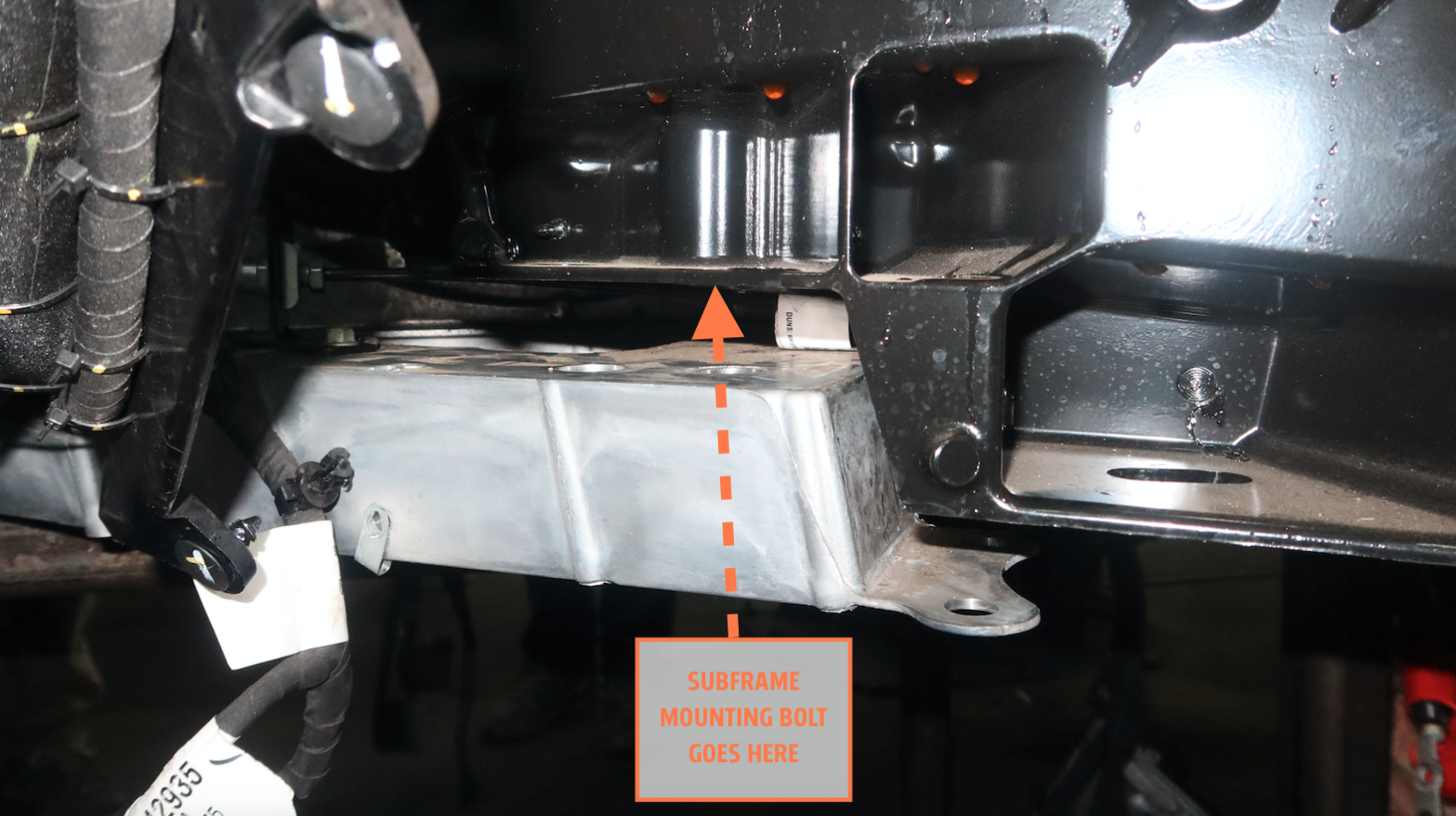

With the struts in place, it was time to install the other subframe bolts. I've labeled a few of them in this image taken from under the car (I took this photo under the car facing rearward):

Here's a closer look at the "subframe-to-body bolt" labeled on the bottom left of the image above:

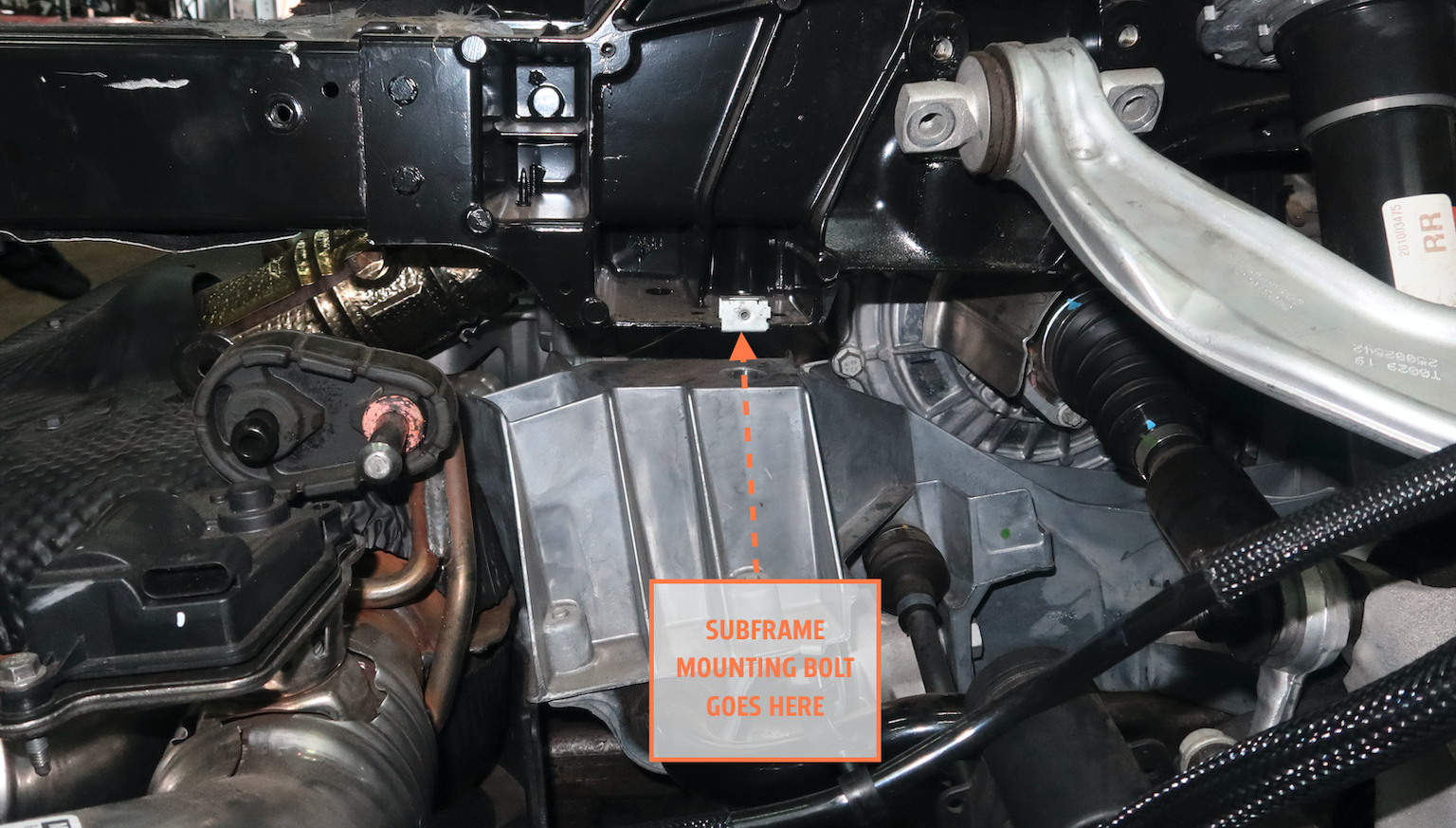

Here's another one of the six or eight subframe-to-body bolt locations:

Fastening the rear upper control arms to the body took a bit of work, as aligning the bar pin holes with the threaded holes in the body required compressing the springs.

The solution was to use the hoist to lower the rear subframe—now affixed to the body via those six or eight big bolts—down onto a block of wood sitting on a metal cart.

The wood pushed up on the rear suspension, allowing the upper control arm mounting holes to line up with the threaded provisions in the C8's tub:

Here is the C8 with the suspension bolted up. I've labeled the active exhaust valve for no other reason than that it's pretty cool to see it out in the open like that:

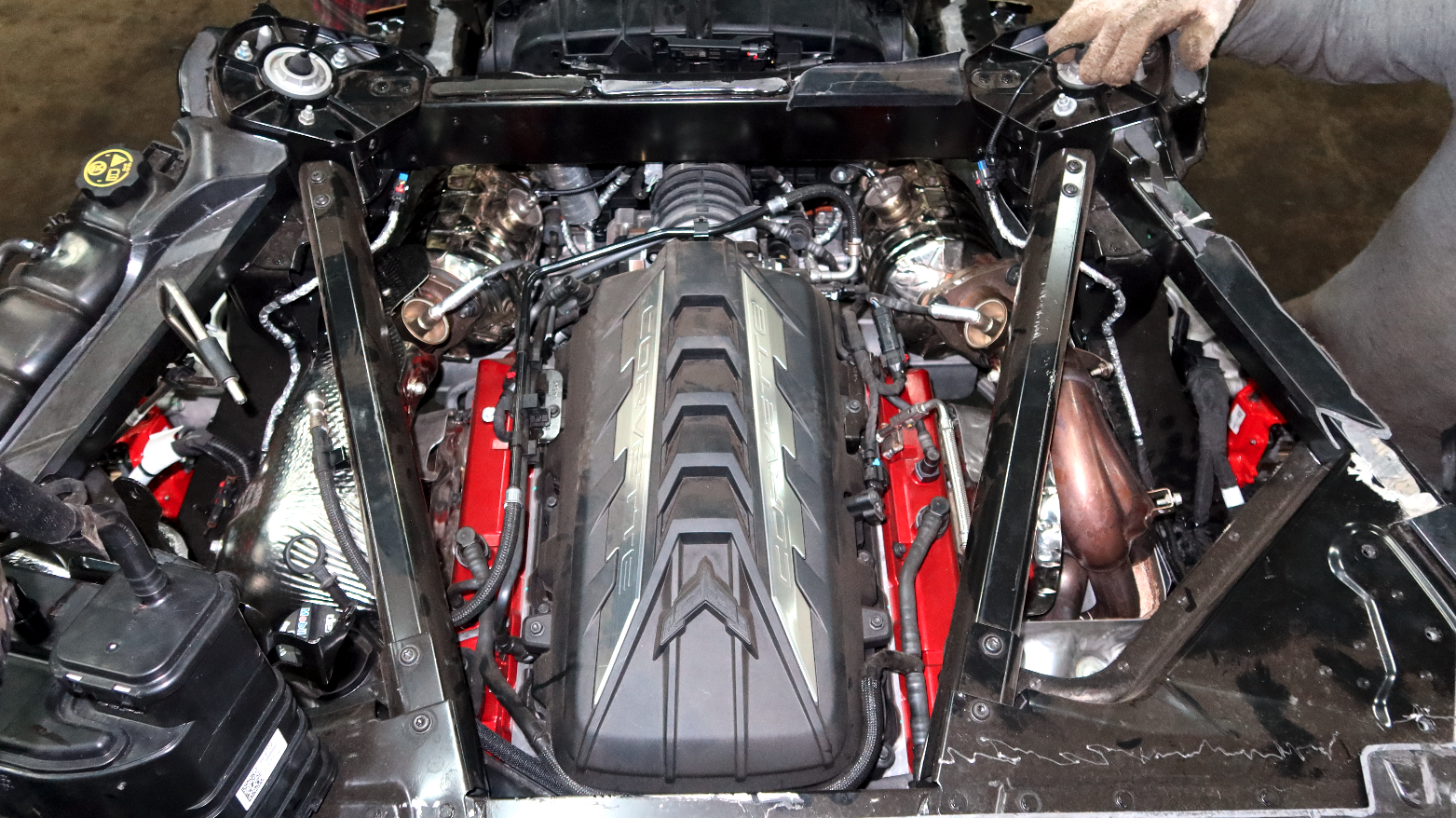

And here's the engine bay from up top:

With the engine and transmission now in the car, Darko and company had to hook up the coolant lines, fuel lines, brake lines and a bunch of electrical connections.

It appears that a main engine controller (the harness that leads to it is shown dangling above) mounts to the bottom of the Corvette, and though it looked to me to have some kind of aero shield incorporated into its design, I'm not sure if it makes up the car's ground plane. It'd be interesting if it did, and if the air flowing over it was used for cooling. (This is just a random thought). Here is that computer:

Emma from Mobsteel, a Detroit-based custom car parts company, took a much higher-quality video than I did. Plus, she stuck around to see the team fill the car with coolant and oil, and hook up enough of the electrical system to actually drive the stripped 'Vette on the street. I bet that was a lot of fun, even if the car wasn't making full power thanks to the required "break-in mode" for the first few hundred miles of Corvette C8 ownership.

"It fired right up like it was perfect. Zero issues," Darko told me, saying he was surprised that the car ran so well given how much of it was still disassembled, and given how many error messages — hood unlatched, trunk lid unlatched, doors open — the car was displaying.

"The car just had a zillion errors on it...but [the computer] still let it run and do what it was supposed to do," he told me over the phone.

Darko remains in the process of reassembling the car (the front end is together, as shown above). He's currently awaiting replacements for the body parts that the previous owner had to destroy to remove. When the red sports car is all together, Darko says, he'll assess how much he likes Chevy's midengine Lego kit and figure out what to do with it from there.