How Does Variable Valve Timing Work?

If we want a new generation of car enthusiasts to care about cars, it can’t hurt to explain how things actually work.

It's springtime! Time to start working on your project car, learn a new wrenching skill, discover what everything is under the hood (and how it works), or just spruce up your daily driver. All month, we'll be looking back at our best informative, maintenance and DIY articles from Jalopnik's near 20-year history to get your ride ready for the road.

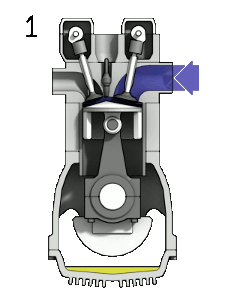

Back in the day, a car's intake and exhaust valves opened a specific amount at a specific point in the four stroke cycle, and for a specific amount of time. It was that simple. Nowadays, however, many engines can not only change when their valves open, but also how much they open and for how long – that is, new cars can change valve timing, valve lift, and valve duration. Let's have a look at how variable valve timing (VVT) works.

For a lot of you this is review, but if we want a new generation of car enthusiasts to care about cars, it can't hurt to explain how things actually work.

Variable Valve Timing

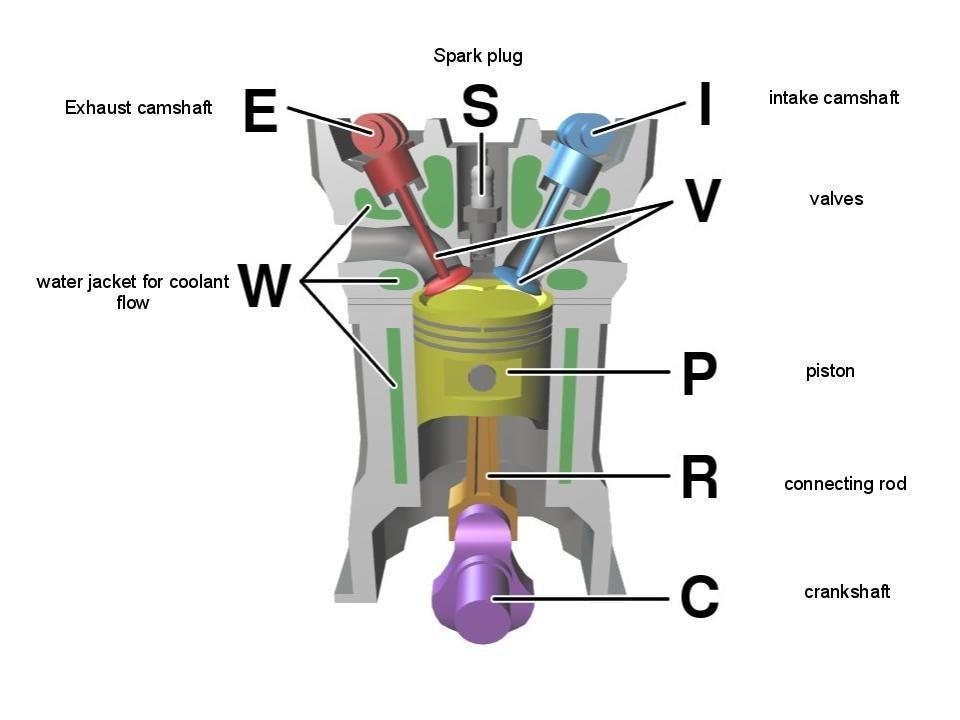

A typical engine's intake and exhaust valves are opened via the lobes on a camshaft. With dual overhead cam engines, there are separate camshafts for exhaust valves and intake valves. These camshafts are made of hardened iron or steel and are connected to the crankshaft via timing belts, chains, or gears. Since modern gasoline engines incorporate the four-stroke cycle, this means that the camshafts rotate once for every two crankshaft rotations.

To reinforce this point, consider the intake stroke of an engine. The intake valve is open, meaning the camshaft lobe is pushing against the cam follower and opening the valve. Let's trace the motion of this cam lobe and compare it to the motion of the crankshaft.

While the intake valve is open, the piston moves down toward bottom dead center. Once the engine has reached bottom dead center, the crankshaft has rotated 180 degrees. Then the piston moves up to compress the fuel mixture. Once the piston has reached top dead center, the crankshaft has made a full rotation.

Next, the spark plug ignites the fuel mixture, sending the piston back down to bottom dead center. At this point, the crankshaft has turned one-and-a-half full rotations. The exhaust valve opens and the piston moves back up to top dead center. The crankshaft has now rotated two full revolutions.

With that piston at approximately top dead center, the camshaft lobe that we are monitoring comes back around and opens the intake valve and the piston moves back down. Thus, after two revolutions of the crankshaft, the camshaft has rotated once.

Different Strokes for Different... Engines

In the 1960s, automakers began developing variable valve timing systems that allowed intake and exhaust valves to open earlier or later in a 4-stroke cycle. The aim was to improve volumetric efficiency, decrease NOx emissions, and decrease pumping losses.

Today, there are two major types of variable valve timing: cam phasing and cam changing. With cam changing, the engine control unit (ECU) selects a different cam profile based on engine load and speed, whereas with cam phasing, an actuator rotates the camshaft, changing the phase angle. There are dozens of ways to go about varying valve timing, lift, and duration, so we're just going to look at Toyota's VVT-i, and Honda's VTEC.

Before we look at VVT-i, let's briefly talk about sensors. VVT systems use all sorts of sensors, but the most important are the camshaft and crankshaft position sensors (which are often hall effect sensors). The ECU uses these sensors to monitor the relationship between the piston's location and the valves' positions. The crankshaft is connected to the rod and piston, and the camshaft's lobes trigger valve lift events. Thus, with the information from the crankshaft and camshaft position sensors, the ECU can learn how fast the engine is rotating and the relative positions of the piston and the intake and exhaust valves.

Cam Phasing

Cam phasing advances or retards valve lift events by rotating the camshaft, typically over a range of about 60 degrees relative to the crankshaft angle. Let's say our intake valve normally opens 5 crankshaft degrees before top dead center and closes 185 crankshaft degrees after top dead center (5 degrees after bottom dead center). "Retarding" valve timing by 10 degrees means the valve opens and closes 10 degrees later, that is, it opens 5 degrees after top dead center and closes 195 degrees after top dead center. By retarding the camshaft's timing, the engine achieves better high RPM torque, whereas advancing the intake camshaft's timing produces better power at low RPM.

There are numerous different methodologies used to vary valve timing. Each manufacturer has its own name for its own VVT system. Toyota uses VVT-i®, Honda uses VTEC®, Mitsubishi uses MIVEC®, and the list goes on. Let's see how Toyota's VVT-i system works.

The VVT system shown in the video above is a variation of Toyota's VVT-i, though Honda has a similar system called VTC. In this system, the ECU receives signals from the camshaft position sensor, crankshaft sensor, oil temperature sensor, mass air flow sensor (MAF), and the engine coolant temperature sensor and uses the information to adjust its output signal to an oil control valve. This valve acts as a hydraulic actuator, rotating a rotor (which is connected to the camshaft) inside a housing, which is connected to the crankshaft via a timing chain. Once the ECU has changed the cam phase angle, the ECU continues to receive inputs from all of the sensors and continually adjusts the oil feed to the rotor.

Like electronic throttle control, this is a closed-loop system, which means that the difference between the current camshaft phase angle and the optimal camshaft angle is the "error signal" that is sent to the ECU. The computer uses the error signal to adjust its output to the actuator to get the camshaft phase angle where it needs to be.

Cam Changing

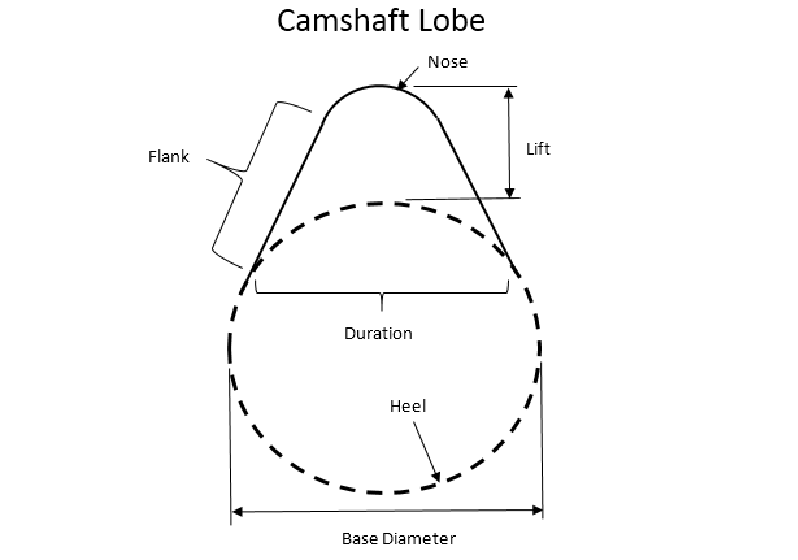

Other VVT systems change the shape of their camshaft lobes, not just the camshaft phase angle relative to the crankshaft. Changing the cam profile not only affects valve lift (how far the valve opens), but also valve duration (how long the valve stays open). The image above demonstrates the features of a camshaft lobe that affect valve lift and duration.

At higher engine speeds, many VVT systems change to a more aggressive (i.e. high lift and high duration) cam lobe profiles. Some variable valve lift systems shift the camshaft axially so that a higher profile lobe engages the cam follower, producing more valve lift. Others, like Honda's VTEC (yo), lock a high profile rocker arm to the low speed rocker arms via a hydraulically actuated pin. A more aggressive cam lobe activates this high profile rocker arm and provides the intake valve with more lift, allowing more air into the cylinder.

For our more visually-inclined readers, Engineering Explained provides a great breakdown of how Honda's VTEC system works.