Here's Why That $25,000 Tesla Isn't Coming

Tesla's costs prevent the company from selling a budget model

Earlier this week, Tesla released its earnings report for the fourth quarter of 2021. The report showed record revenue, but it came with the news of delays to the Cybertruck, Roadster, and an unnamed budget-minded model. Elon Musk's reason for the delay was that the company had "enough on [its] plate right now," but Tesla's investor presentation tells a different story: With an average cost per car of $36,000, the company simply can't afford to build a car that cheap.

That figure is buried deep within Tesla's Q4 2021 earnings presentation. That's not to say it's hidden — it's just less interesting to most people than the big shiny profit news up front or the big shiny pictures at the back. The average cost to build a Tesla being $36,000 seems fine when the cheapest model you can buy is $44,990. The company still makes nine grand on that deal, right?

Well, not necessarily. Just because we know the cost to build a Tesla doesn't mean we know the costs of everything else at the company. Sure, there's no traditional PR or marketing department, but there are still administrative costs associated with running a company. Somebody's gotta pay the power bill in Fremont. Luckily, Tesla gave us some clues to help figure the rest out.

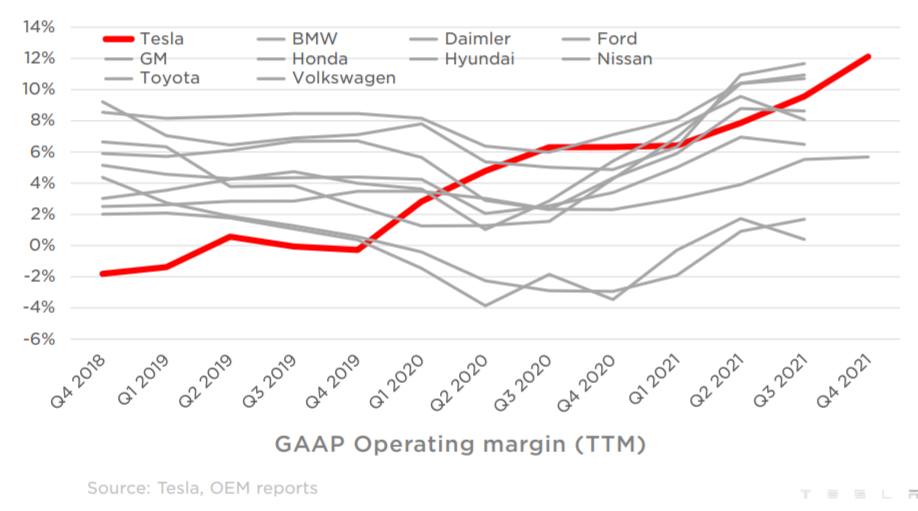

In the world of business, we have a metric called operating margin. It's a measure of how efficiently a company operates, and it's calculated by taking a company's earnings (what's left of the company's revenue for a given period, after costs are subtracted out) and dividing them by the overall revenue for that period. Tesla claims to have the highest operating margin of its competitors, just barely peaking over 12 percent.

So, 12 cents of every dollar Tesla brings in from selling cars is pure, sweet profit. The average Tesla costs $36,000 to build, and the company sold 936,172 cars in 2021. Tesla's automotive revenue (not counting flamethrowers, booty shorts, etc.) was $47,232,000,000 for the same year. We've got our numbers, let's start running them.

$47.232 billion dollars divided between those 936,172 cars comes out to an average of $50,452.27 per car. Subtract out our $36,000 build cost, and we're left with $14,452.27. We know that 12 percent of that 50-plus-thousand-dollar number, or $6,054.27, is pure profit, so pulling that from the fourteen grand figure leaves us with $8,398 in average non-manufacturing costs per vehicle.

Tesla has stated that the reduced cost per kWh from its new 4680 battery cells is crucial to making a $25,000 car financially feasible. The quoted 14 percent reduction in cost, however, isn't nearly enough to balance out the rest of the price of making a new Tesla. Forbes estimates the cost of an average Tesla battery at $9,000, which would come down to $7,740 with the 4680 cells. Adding back in the rest of Tesla's costs, however, comes out to a total of $43,138 in manufacturing and administrative costs per vehicle.

Tesla may have had record profits in 2021, but the company can't afford to eat $18,138 on a high-volume budget model. Until the company's costs come down, that $25,000 economy car will remain a twinkle in the eyes of Tesla fans everywhere — and maybe of Musk himself.