Here's Everything Wrong With My School Bus Camper Project

A few months ago my significant other gave me a school bus for my birthday. It's a dream come true, and I can't stop thinking about what I want to do with it. Now that we have a platform to build a camper on and it's legal for me to drive, it's time to get our hands dirty. But before I dive too deeply into the camper build, I need to square away a few issues.

This International 3800 chassis school bus ran routes for a district in northern Wisconsin. When the school was done with it, an employee of the school took it home and stashed it on his property. Three years later, the bus is now in my hands. Under the hood is a 7.6-liter International DT466E straight-six diesel paired with an Allison AT545 transmission. Together, they move a 65-passenger body by AmTran. Considering that I didn't pay for this bus, I have no complaints. But there are a few areas I'm looking at fixing.

Electrics

I love myself a good electrical demon to vanquish and the bus wants to give me a challenge. About halfway home from pulling the bus out of the previous owner's yard I noticed the lights flickering at idle. I peered down at my gauges and saw the onboard battery gauge pulsing at around 16 volts. The needle bounced with the same frequency of the flickering lights.

As I continued to drive home I noticed that when the accelerator pedal was welded to the floor, the needle backed down to a more reasonable 14 volts. Huh, that's odd.

Alright, so what could be going on here? I've not yet to finish my research, but I think it could be a bad ground or a dying voltage regulator. The issue could be caused by a dying alternator as well. However, as the voltage regulator lives in the alternator, the repair for either the regulator or alternator is still replacing the alternator. A friend with a similar bus experienced this issue and found his alternator to be putting out a whopping 17 volts.

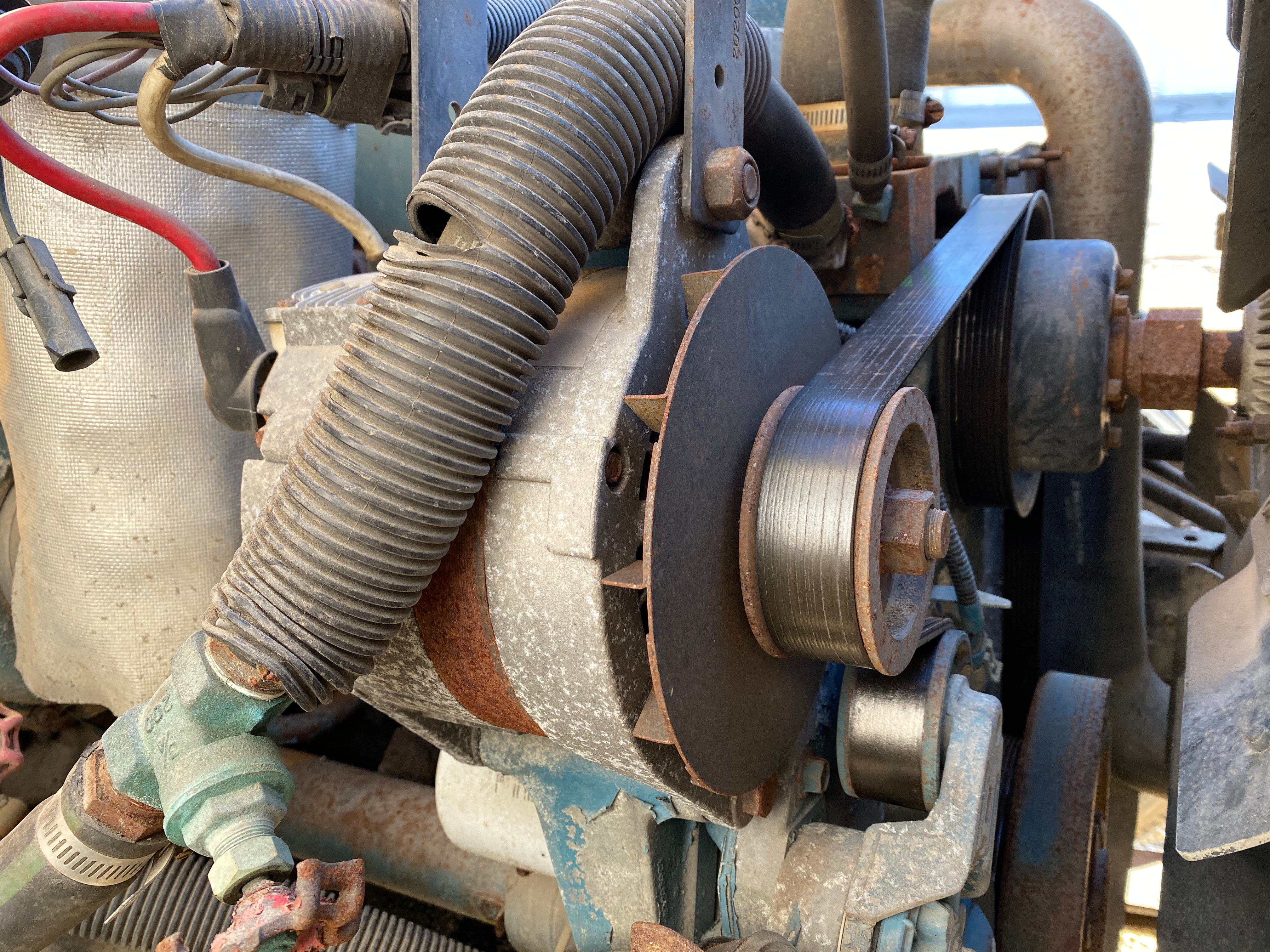

This is why I went with a conventional style bus. Not only do I have a rear door I can load motorcycles through, but repairs and maintenance are easier than a cabover. All I have to do is swing open the hood to reveal that beautiful DT466E and all of its accessories.

Check out the massive alternator on this thing. I would be surprised if replacing an alternator takes longer than 30 minutes on this bus.

I'll be sure to thoroughly check voltage through the system before throwing parts at it. Aside from the voltage oddities, the electrical system of the bus is strong. There isn't even a parasitic drain on the batteries.

Rust

If you buy a school bus from deep within the Midwest you will have to deal with rust. For anyone getting into building a skoolie, I highly recommend going down south. If you can't, at least make sure the bus you're getting has good floors and a good frame.

Thankfully, that's what I see here with our bus. The frame looks great in most areas. In fact, it looks just barely broken in up front.

The worst part of the frame is this section in the rear, directly behind the rear wheels. However, the thickness is uniform and the frame beams are solid so I think I should be able to grind away that rust and get some POR-15, a rust preventive coating, in there. The inside of the beams still have paint on them. If I had to wager a guess, salt kicked up by the rear tires did this.

Once all the rust is gone I'll treat the whole thing in POR-15. The other good news is that I've yet to find any rotted spots on the floor. It appears the floor was coated with some material in its past and it seems to be doing its job.

The body has a couple areas of concern. On the right side I found the bus's rear wheel well to have some rot on the outer panel. The left side appears to be clean, thankfully.

There are a few rust holes in back, namely on both sides of the door. I will cut out the rust, weld in a patch and treat the area with POR-15. Thankfully it's all flat and somewhat thin steel, so I don't think it'll be too difficult to fix.

I've never used a welder before, so that alone will be an interesting adventure. I'm planning to follow the ways of David Tracy and getting the cheapest welder money could buy. When I'm satisfied with the rust repairs, the bus will get painted sky blue and white. I'm still not quite sure how I'll do that yet. But I will power wash the bus to get rid of the moss growth everywhere.

When we originally began our search for buses, it was scarily common to find buses with far more rust despite fewer miles and newer model years. I almost fell through the rotting stairwell of a Blue Bird. So ours isn't perfect but it could be worse. Salt is an absolute menace and again, I definitely recommend going south if you can.

Alignment

The bus has a faint pull to the left at higher speeds. I originally thought maybe the tires were just low on air but they weren't. While checking tire pressures I discovered that the front tires have more wear on the inner edge than I'd think would be normal. This one seems simple enough: I'll take the bus to an alignment shop to have it straightened up.

So far it seems repairing this bus will be a bit like repairing a car...only that car was run through Photoshop and scaled up 500 percent.

I don't think any of these issues will be too hard to overcome. In the meantime we've already begun removing seats and adding in some furniture. I'll also need to reseal one of the windows on the entry door.

To assist in our build I'm picking up a 5,000 watt generator. During the winter build process it can provide power to tools and heat for our bodies. Then when we're ready to begin camping it'll provide power to the bus itself when camping in the boonies.

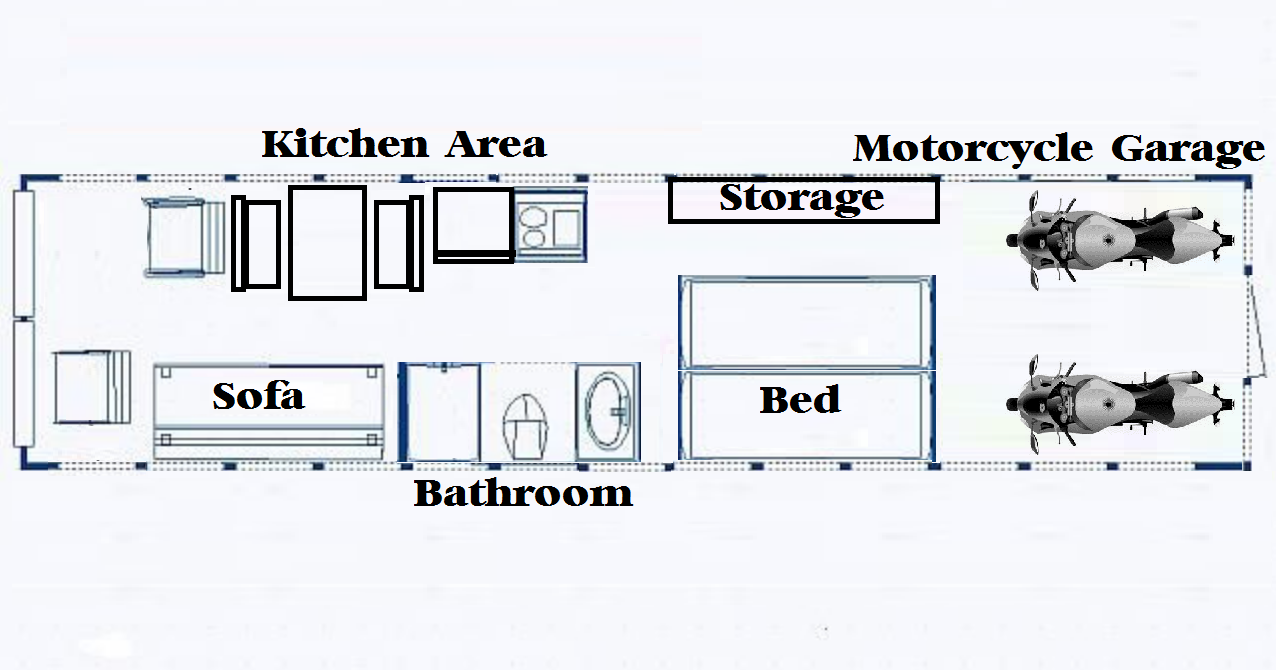

I made a very rough floor plan of what I want to do. My end goal is sleeping for up to four, a motorcycle garage in back and an overall open layout. Again, this is really a rough idea of what I want to do. It's not really even to scale.

At first we'll build out a dry camper, then later on we'll start adding running water and more. My working name for the build is Project Spool Bus. Stay tuned because we're just getting started on this rig!