Here Are Your Biggest Car Repair Mistakes

Most of us have messed trying to fix a car before.

I've always played it safe when dealing with my vehicles. Usually, because I use my vehicles daily, but I was young and dumb once. Years back, when I had my TL Type S, it somehow developed an engine mount issue. There was a clunk when I would accelerate. I attempted to see what the problem myself after seeing how much labor would be for the repair, but I quickly found myself in over my head after seeing three engine mounts. I gave up after removing the front motor mount plate. The car ended up having to be towed and I just took a hit on the repair because I couldn't do it.

We asked readers what their biggest car repair errors were. These were their answers.

This story was originally posted on May 24, 2021.

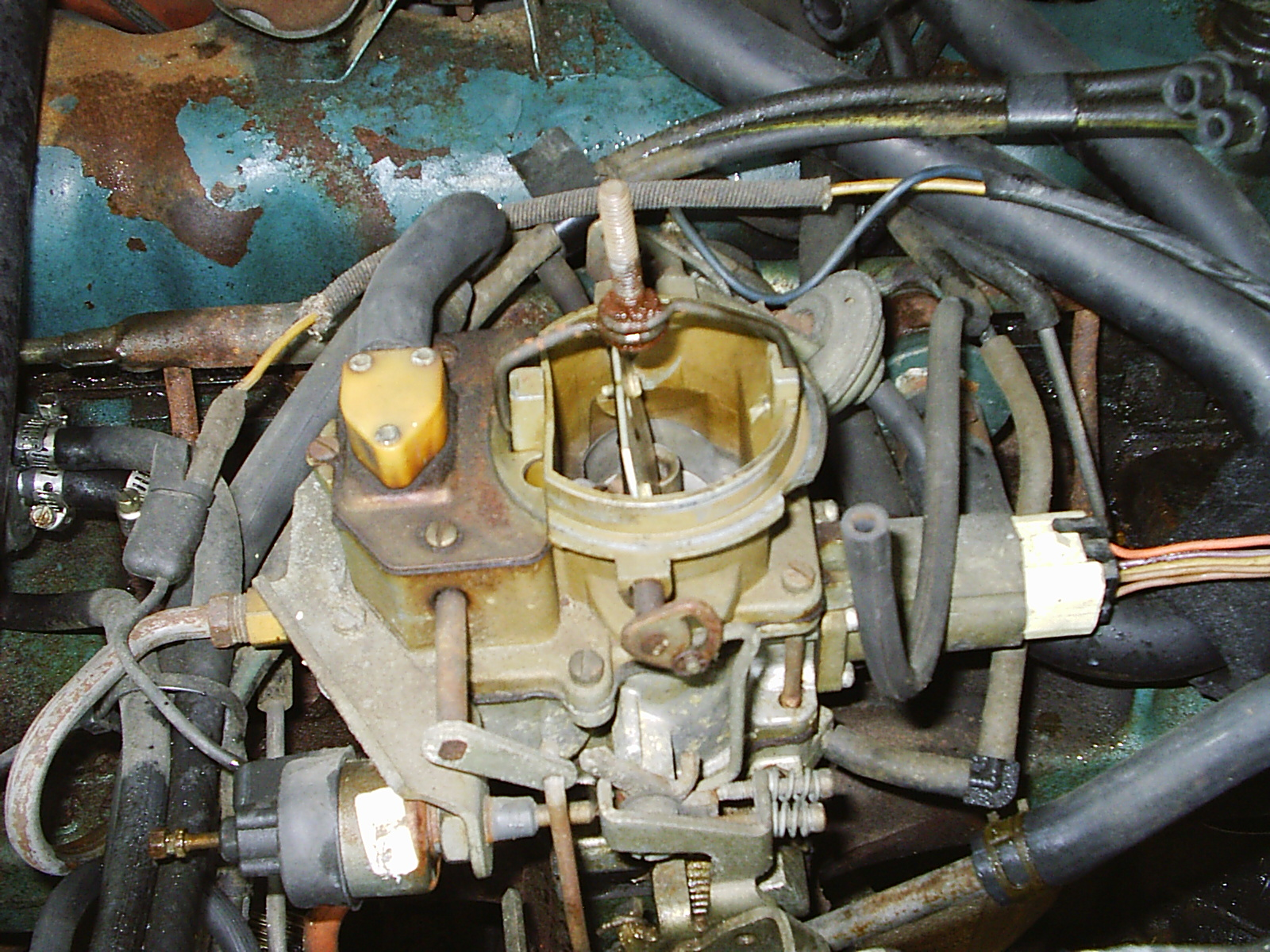

Rebuilding A Carb In A Room

I once rebuilt my carb in my dorm room in college. I thought having both windows open would be adequate ventilation. It was not. I got sooooo unintentionally high.

Suggested by: Mike Rinck (Facebook)

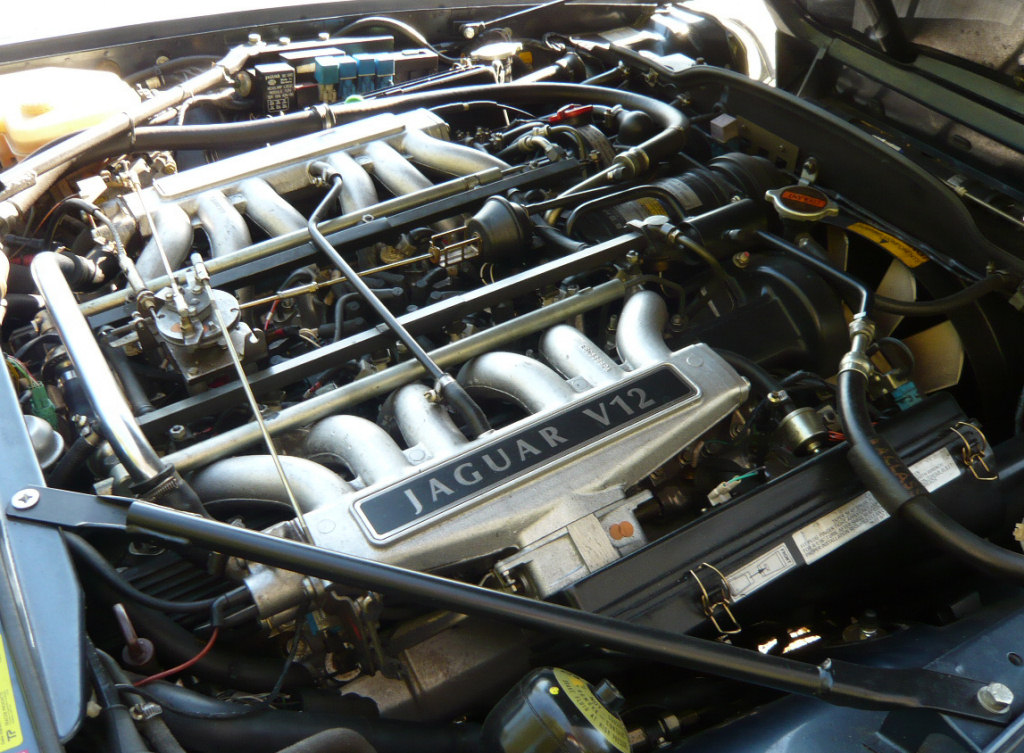

Dropping Valve Springs Into a V12

I am with David on this one. Dropped 3 Valve Stem Keepers into the bowels of the V12 while I was doing the Valve Stem Seals. I was using a torch to soften them up and I would take out the paper towel blocking the oil drains so as not to start a fire. They are still there, I checked after I changed the oil. I had extras before I started though. I knew better, they are a PIA to get in and get out. I also lost one of the valve spring keepers to an errant flink as the tool slipped. And then I pinched one of the valve cover gaskets which caused an Oil Leak and another 6 hours taking it apart and cleaning off RTV Ultra Black off the manifolds.

Suggested by: Bob

Bad Starter On A ‘94 Legacy

Some time ago I had a 1994 Subaru Legacy that had a bad starter. I grabbed a replacement from the junkyard and installed it and everything was fine.

The following Saturday morning the car wouldn't turn over, the starter making a dull clunk noise every time I turned the key. I assumed the replacement starter had also gone bad so I had a friend drive me to the auto parts store to buy one that presumably was going to last more than a week.

After removing everything I needed to in order to get to the starter I realized I hadn't disconnected the battery. In doing that I found out I'd never tightened the negative battery terminal after installing the starter the previous weekend. I tightened it down and turned the key and the car fired right up.

Half a Saturday wasted. The junkyard starter worked fine the rest of the time I had the car.

Suggested by: As Du Volant

Saab 900 Mistake

In 1995, driving a 1984 Saab 900 on I-90 east of Cleveland in a heavy lake effect storm. Car up and dies. After an adventure that incudes walking a mile in a blizzard on an interstate, spend the night trying to diagnose it in the parking lot of a dive motel. Finally give up, rent a U-haul and a trailer the next morning, and tow it to my dad's house in Buffalo.

Somewhere around Dunkirk NY, I have a recollection of a mechanic telling me that era Saab had a cutoff switch that, when the coolant got too low, would stop the engine to prevent overheating and fire. So finish my trip by pulling into the driveway, open the rear hatch, pull out the gallon of antifreeze I carried in back for just such an eventuality, pour it into the radiator. The car starts right up, and I drive it off the tow trailer.

Spent several hundred dollars towing a car that had the solution to the problem inside it the whole time. Told my dad "We will never speak of this to anyone, ever."

Not a "car repair" error. But certainly an idiotic mistake.

Suggested by: tom.blersch

Buick 455 Rebuild

I farmed out the rebuild of my Buick 455 to a local engine guy, who farmed it out to a guy who specialized in Buicks the next county over, who farmed out the machining the heads to his brother-in-law's shop, who took them to a shop in SC because his machine was down, but his driver lost the receipt....

So I had most of the car in the shop in my town, the block, pistons, crank etc in a town 35 miles away, with new valves and springs, still in their boxes, in another shop 20 miles away from that, and my original number-matching heads in a completely different state being held hostage by someone who never answered the phone and whose VM was full.

it took six weeks, several dozen angry phone calls and a letter from an attorney-friend (who is actually a divorce lawyer) to get everything back in the same zip code, and another month to get the complete engine back into the car.

Suggested by: Earthbound Misfit I

1998 Honda Civic Spark Plug Change

My 1998 Civic had never had a plug change and at 140K I thought it was something I could manage. Bought plugs and wires and three out of four plugs changed without incident. Plug 4 was quite stubborn. Long story short, I snapped it off at the insulator. Drove it on three cylinders to my guy and my guy fixed it for 400 bucks. Now, I have instructed my spouse that whenever she sees me approaching the car with a tool in my hand she is to take said tool from me and hit me with it until my desire to repair has subsided.

Suggested by: oldjohn

2001 BMW X5 Suspension

How about managing to avoid one this weekend?

After refreshing the rear suspension of my X5, I decided to replace the ratty looking wheel speed (ABS) sensor. I've been haphazardly working on a dash trifecta in the car since I got it – fairly certain it's the ABS module, but figured I would replace some of the original (20-year old) wheel sensors (frayed wire covers, ugly connectors, etc.) Logic being that the one that tested bad has been replaced, but still tests bad, so maybe (just maybe), it's erroring out because all of the others are bad! (give me a break, going on BMW logic here!)

I went to remove the allen bolt holding the wheel sensor in place, and the head snapped right off. No biggie, I'll just replace the bolt after I pull the sensor out. Went to start prying the plastic piece up, and the plastic starts disintegrating. Ok – that's no good. Let's start gently wiggling it back and forth and – whoops, that just snapped in half. At this point, I was getting ready to pull the drill out, but after staring at the piece, I realized that all of the actual wires for the sensor were pristine (even the ones under the broken plastic sensor housing). I stared at it for another good 5 minutes, wire cutters in my hand, getting ready to cut it flat so I could start drilling. After another 5 minutes, I realized that this sensor was probably fine, and I slowly put down the wire cutters, picked up some plastic putty and electrical tape and patched everything up.

I'm fairly certain that if I made that cut, and as corroded as things were looking, I would have progressed to the point of removing the entire rusty hub.

Suggested by: wuzilla

Mercedes W123 Brake Job

Doing brake calipers on a W123 Mercedes.

The passenger side went fine. On the drivers side, I had a hell of a time. I was removing the steering tie rod bracket to get better access, but I could not get one of the bolts out. I ended up getting an enormous breaker bar, put all my weight on it, and I snapped the head clean off. I then looked down at my wrench and realized I was tightening the bolt rather than loosening it. Oopsie.

Okay, so I tried to get the broken bolt out with an extractor. Nope. So I spent an incredible amount of time drilling it out. Okay, no problem. I'll just drill and tap for a larger bolt. Then I broke the tap off in the hole.

At this point, I'm so done. I called a mobile welder and he came over and just welded the bracket to the spindle. It's been like that for like 3 years.

And then I spent all this time bleeding the brakes and couldn't get it right. The pedal was all mushy. I broke down and took it to a shop. The master cylinder was bad, too. This was all over the course of like 3 weeks.

Suggested by: Unacceptably Dry Scones

Ford Aerostar Ball Joint

I had a '97 Ford Aerostar with a worn upper ball joint. The front upper A-Arm was bolted to the top of the frame rail with a few bolts. Easy peasy, right? Nope! Those bolts were insanely tight! And there was no room there for an impact wrench, and the angle was less than optimal for wielding a wrench anyways. I broke a socket and bent a breaker bar. I bought a special wrench with a bend in it. Didn't work- I just bent that wrench. After that I got cute and had a shop custom bend a wrench to a more optimum angle and re-harden it. The bolts still wouldn't budge.

Finally I consulted the manual (DUH!) Turns out there were nuts underneath that you could access through holes in the frame rail! The nuts loosened right away! I had put up with that clunking front end for the entire 3(?) years I owned that van.

Suggested by: icemilkcoffee

Jeep CJ7 Dash

I once tore apart the entire dash on my CJ7 trying to find a broken wire. It turns out the glass fuse had a broken end. So the fuse looked good, but didn't actually conduct electricity.

It took me 8 hours for a 30 second fix.

The upside is I really learned what was up in those hard to reach places.

Suggested by: jason

Chrysler Town & Country Spark Plug Change

Spark plug change on my wife's 2015 Chrysler Town & Country. Access to the rear plugs requires removal of the upper intake. No problem. Got some shop towels, plugged the intake runners to keep from dropping anything inside the motor, and go to the plugs.

Comes time to start it up and make sure it's working. Engine coughs a couple times and stalls. Weird. Try it again. Same. I start looking at the motor – it's not a plug wire issue as it's coil on plug. Then I look down in my trash bag. The trash bag doesn't have 6 Scotts Shop Towels in it. Uh oh.

Pull the intake back off and found the shop towels were partially consumed by the motor. I cleaned out what I could but shop towel was everywhere. I ended up having it towed in for repair. They had to remove the heads to get everything out. Towel shreds had made it all the way to the catalytic converters.

My plug repair ended up costing 26 hours of shop labor for a top end teardown. Fortunately nothing was damaged – all the replacement parts were consumables such as gaskets.

Suggested by: mtbchris

Toyota Tacoma Differential Fluid

Oh....I have this one won easily. My 2015 Tacoma was coming up on it's 90k service and the shop wanted $100 to change the rear differential fluid. I assumed it would be an easy task that could be done much cheaper..... I'd never owned or used a torque wrench, but all the YouTube videos said to torque the fill plug to a certain spec. I borrowed a fancy digital torque wrench from a former coworker and got to work, but it was apparently broken and never beeped. I kept turning like a moron and stripped the fill plug. I had to cram a wine cork into it's spot, so I could drive the truck to a shop and have them tap the treads to accept a larger plug. $650 for what I could have just paid someone $100 to do.

Suggested by: Ryan Servizzi