Chrysler Built Hemi Engines With A Major Engineering Defect And I May Try To Profit From It

One reader reached out to me to see if I’d like to buy his 2011 Jeep Grand Cherokee that appears to have suffered this fate, and I may take him up on it.

We may receive a commission on purchases made from links.

It appears that Chrysler royally screwed up, and owners of 2011 Jeeps, Dodges, and Rams equipped with the legendary 5.7-liter Hemi have paid for it dearly. For some reason, the engine's valve lifters have a tendency to seize up and wipe out the camshaft, leaving customers with enormous repair bills. One reader reached out to me to see if I'd like to buy his 2011 Jeep Grand Cherokee that appears to have suffered this fate, and I may take him up on it. There's money to be made, after all.

I've never bought an automobile with the intention of selling it for a profit. Something about the concept just doesn't jive with how I view cars and car culture at large. To me, these are more than machines; they are soulful, characterful mechanical beings that deserve far more than to be purchased and then quickly flipped. I always cherish every vehicle I buy, even if I do eventually decide to part ways with it. That's why I'm on the fence a bit with my next endeavor.

“Flipping” A 2011 Jeep Grand Cherokee

The idea came to me after a reader named Brian sent an email titled "2011 Grand Cherokee Woes." The body of the message described the tragic failure of his girlfriend's luxury Jeep SUV:

My girlfriend's 2011 Grand Cherokee Overland 5.7 decided to destroy itself this week. She called me the other day while driving home from work saying that the check engine light was blinking and the car was shaking violently.

When I read the code, we found out that it was a misfire in Cyl 1. I tried replacing the coil and spark plugs, but it the misfire was still happening. After taking it to a local shop, we found out that the pushrod was "bent like a pretzel".

The 180,000 mile SUV, Brian fears, needs a new motor, which is why the Cincinnati resident thinks it's time to part ways with his first-model-year WK2-generation Jeep. The email ended with a question: "Do you know anyone who would be interested in buying this for parts or as a project?"

Gears began turning in my head.

On one hand, I already have a ton of projects. I have a 1979 Jeep Cherokee Golden Eagle that needs motor work, I have a Willys with a blown engine, I've got a Jeep Cherokee XJ with a bad front axle, I have another Jeep Cherokee XJ that could use a new cylinder head, and there's that totaled Kia I'm trying to prepare for a rally in May if that's not canceled.

But, on the other hand, Brian is only asking $2,500, and a working 2011 Jeep Grand Cherokee Overland with high mileage is worth around $7,000 to $8,000 based on what I've seen on Facebook Marketplace (granted, the economy has since tanked, so who knows what that does to the market value).

Based on some cursory research, I bet I could fix this Jeep for about $1,000 (I'll get into details in a bit), so, even considering trailering costs, there's probably at least $3,000 of profit potential. This is enticing for me not because I need cash to stock up on toilet paper and canned goods, but because I have a very ambitious wrenching/engineering project in the works. One that will put Project POStal, Project Slow Devil, Project Redwood, and Project Swiss Cheese to shame in terms of sheer difficulty, and also in terms of how insightful I think the stories will be. But above all, the project is sure to be ridiculously fun.

The issue is that this endeavor is going to be expensive, and while I hope Jalopnik will foot the bill, things aren't looking good, especially after the budget tightening resulting from COVID. And since not doing it isn't an option, I'm going to have to scrounge up some cash to get this ship off the ground.

There are lots of ways that I could do that—I've considered starting a modeling career, or selling artwork made of rust fragments left behind by my junkers—but I'm thinking this Grand Cherokee is a pretty smart way to go. Risky, sure, but also, in some ways, pretty logical. Flipping this Jeep would be a project on its own—a source of content for articles. I get to learn how to wrench on a new-ish HEMI, I get to share my peril—I mean, success—with readers, and I can use the bread from the sale to do even more wrenching. Only downsides, really: This Jeep could be in worse shape than I think, and even if it's not, fixing it is going to suck. Badly.

2011 Hemi Engines Have A Major Design Defect

I've been searching the web to see what this Jeep's problem might be, and I'm pretty sure I've honed in on the culprit: A seized lifter roller. A valve lifter is an engine component that rides on the camshaft (shown inn the middle of the photo above), which is rotated via a chain or belt by the crankshaft, which spins thanks to the reciprocating motion of pistons being displaced by combustion events in the cylinders.

As a camshaft rotates, its egg-shaped lobes push up on lifters (shown at the top and bottom of the image above), which are filled with oil to maintain zero valve lash (i.e. to make sure there's no clearance between parts that should be constantly riding on one another, preventing noise and wear, and allowing for quicker valve opening and closing for improved performance). On the other side of a hydraulic lifter from the camshaft is a pushrod, which reaches up and presses against a rocker arm that ultimately opens a valve to let air into or out of a cylinder.

Here's an incredible 18-minute long video that Chrysler released in 1954 to show off the magical inner workings of a hydraulic lifter. If you want to deprive yourself of such an awesome old-timey production, skip it and check out the short video animation later in the article:

My research seems to show that 2011 Jeeps, Rams, and Dodges equipped with the 5.7-liter V8 were highly susceptible to lifter failures. I texted a tech at an FCA dealership; here's what he told me:

Just looking at Carcomplaints.com, I'm seeing dozens of grievances related to this problem. Someone from Wilson, North Carolina wrote about how the issue sprang up on their 94,000 mile Grand Cherokee:

The biggest defect with the car is the V-8 hemi cam shaft and lifters. Every mechanic I have taken my car too has said that Jeep knows it is a problem but will not fix. I was driving 70 mph when my Jeep lost power and the check engine light came on and started flashing which with the loss of power cause me to just about have a wreck on the highway. It was a very scary scenario. I took it to my trusted mechanic who foudn a cylinder 2 misfire & performed a tune up and he said I needed to report the problem to Jeep as they are known to have sever problems. The dealer charged me to "diganose" the problem and reported back that the lifters and cam shaft need to be replaced...My car has less than 100,000 miles and has been meticulously maintained and now lookin G at rebuilding an engine...there is a fatal flaw with the V-8 hemi.

Someone from Waukesha, Wisconsin describes a similar failure mode (this one, and others from Carcomplaints.com can also be found in NHTSA's official complaints database), and talks about the egregious $4,600 repair estimate:

Vehicle had a misfire in cylinder #3. took to Jeep dealership to diagnose and they found a rounded camshaft and bad lifters. Vehicle has 104,000 on it and I inquired as to options. #1 – $4,600 repair (min if they do not find anything else)...Find it surprising and unacceptable that with a little research you can find that the 5.7 hemi has numerous complaints about rounded camshafts due to bad lifters.

Someone from Phoenix also had such a failure on their 135,000 mile vehicle. "Lifter seized in #3 cylinder causing cam failure while driving," the owner writes.

A gentleman named Glen from Victor, Idaho described his pricey experience, writing:

It looks like $4000.00 to replace cam and lifters, whenever they catch up to the back orders. Then when you get to 120,000 miles do it again. Sick and wrong... or replace motor $5000.00 to $8000.00 and when 120.000 miles rolled back around do it again, WTF .... its not just Grand Cherokees its any thing with a 5.7L V8 MDS VVT Engine.... sweet.

Update from Nov 11, 2018Hi ...! I have now fixed my 2011 jeep grand cherokee laredo x 5.7... it cost $3950.00 to replace the cam, roller lifters, mds plugs, reprogram the computer...

Obviously, we don't know how these owners went about maintenance (specifically, I'm curious about oil viscosity and oil change frequency), and we don't know the failure rate, but these lifter faults seem like a significant issue, and I haven't even shown you the complaints for 2011 Ram 1500s.

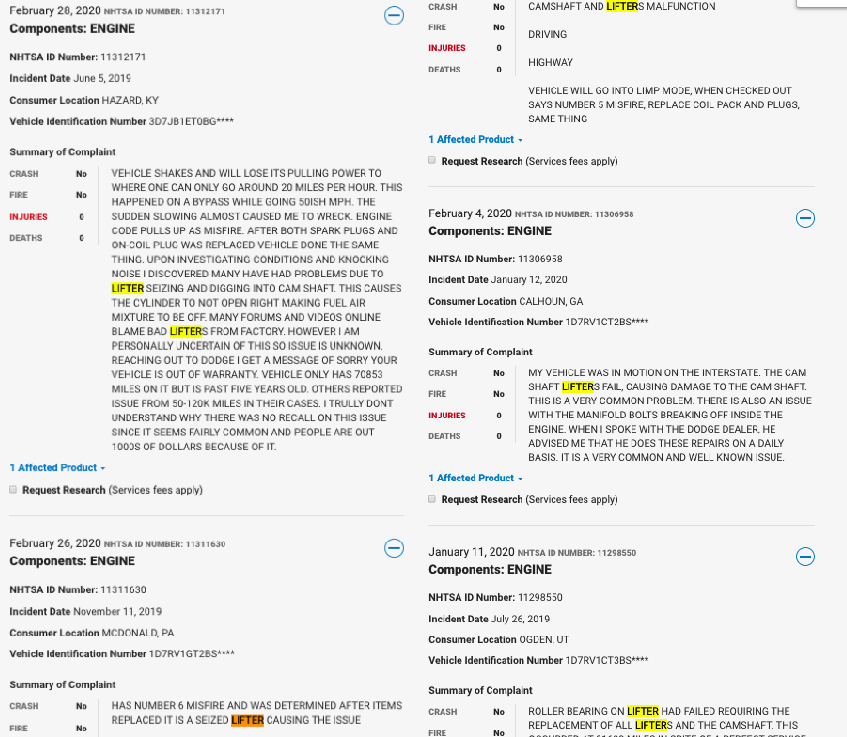

Check out Carcomplaints.com, and you'll see over 30 dealing with lifter and cam problems on 2011 Ram 1500 Hemis. And here's a look at the first page of the "Engine" complaints in the 2011 Ram 1500's NHSTA database:

The 2011 Durango's NHTSA complaints database also features word of lifter failures, and there's plenty of discussion about all of this on forums like Ram Forumz. In fact, there's an entire thread on there called "Ram hemi cam/lifter failure thread." It features 904 posts across 46 pages, and based on it, I've gathered that the vast majority of complaints involve 2011 models, though a few Hemis from other model-year vehicles are also mentioned.

Fixing The Failure Is The Biggest Pain In The Ass

Few of these complaints mention bent pushrods; they just mention a worn-down cam and lifter. I find that a bit odd, though I did find someone on Dodge Forum talking about how he had to replace his 2011 Ram's Hemi engine after discovering his rods pretzeled.

Even though all I know is that his Jeep has a bent pushrod, I'm still fairly certain that Brian's 2011 Grand Cherokee is suffering this dreaded lifter issue. It's the exact same year that seems most plagued by the problem and it's exhibiting the same symptoms (misfire in one cylinder, violent shaking, check engine light). Perhaps the pushrod bent because the worn cam allowed for lots of play in the valvetrain, and the pushrod ended up binding? I'm not exactly sure.

As for why all of these Hemi lifter rollers are seizing up and wearing out camshaft lobes, I don't know that either, but it seems like there's some sort of lubrication deficiency.

In all of these cases, a roller "follower" (the cylindrical thing shown above) eventually ejects its needle bearings and winds up with lots of play, ultimately seizing up. So, instead of it rolling along the camshaft lobe, the follower slides, and chews up the cam as shown in the image (you can see higher-res images of a failed 2011 Charger Hemi here and here).

I'm still not certain what the root cause is, but lots of people seem to think the Hemi's Multi-Displacement System—which uses special lifters to mechanically decouple valves motion from motion of the camshaft lobes, thereby "shutting off" cylinders for better fuel economy—is playing a role. You can see how those MDS lifters work in the animation below:

I reached out to a powertrain R&D engineer at a major OEM, and he gave a little breakdown of how MDS works, writing:

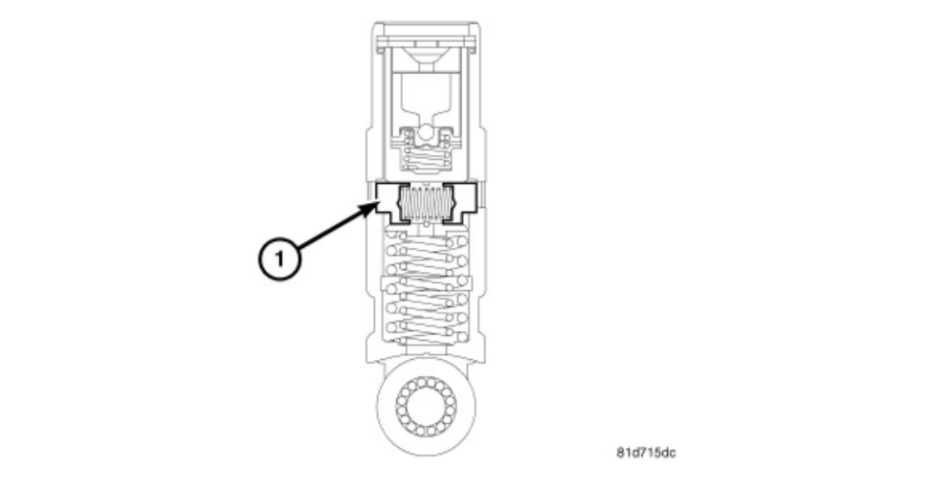

Essentially, there is the normal [hydraulic lash adjuster] on one end that acts on the push rod, the roller-end that follows the cam lobe, and a hydraulically actuated pin (#1 in the first image...below) that holds the two ends together in normal operation so that pushing on the roller moves the HLA-end, in turn moving the push rod etc. When cylinder deactivation is requested by the ECU, a hydraulic valve elsewhere in the engine...feeds oil pressure to that pin, pushing it out of the way and allowing the roller to move independently of the HLA so the cam lobe still pushes the roller, but that motion isn't transferred to the HLA (lost-motion system). Therefore, the valves themselves are never actuated and spring pressure holds them closed.

But in the video clip at the top of this section, the host says the failed cam shown came out of a vehicle without MDS, so who knows what role the cylinder deactivation system played in the failures, if any.

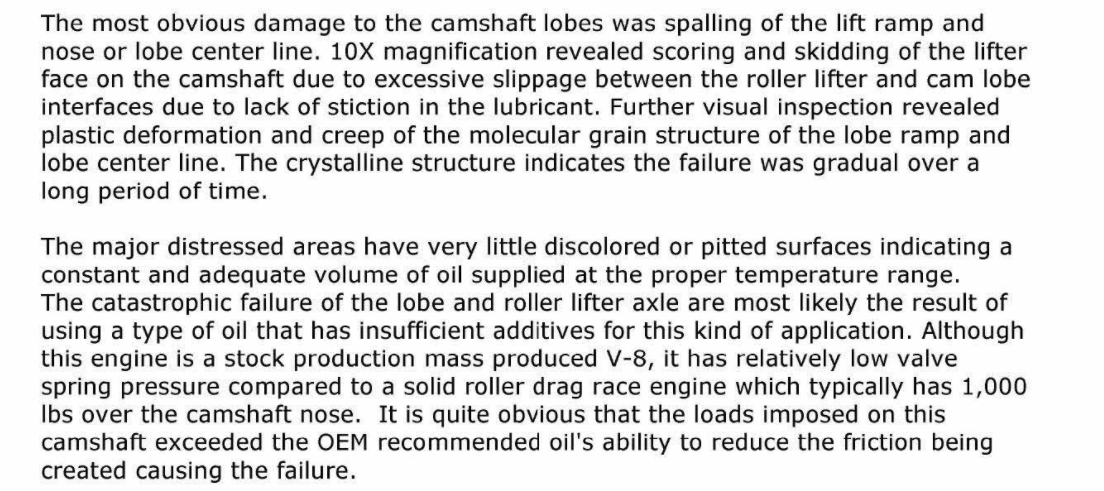

Forum members have spent lots of time and resources trying to determine what exactly is the culprit. One vender on Charger Forums, 370 HEMI, obtained failed parts from user CE9311, and sent them to Steve's Machine Shop Service for testing. Steve, who apparently has a background in engine building and failure analysis, writes in his response that the predominant cause of the wear appears to be inadequate lubrication given the load between the lifter and cam (this doesn't seem surprising, since the follower was supposed to roll, not slide). Here's a look at that assessment:

Steve writes later in his analysis that, to put to bed speculation that plastic lifter guides (which I point out later in this article) or the MDS system are contributing to the issue, he'd like to have a look at another set of failed parts that had been used with a higher quality racing oil.

The aforementioned powertrain R&D engineer at a major OEM, who hasn't looked at this specific issue much more than just watching the video below, gave me a few thoughts. He named three things that could cause the cam/lifter failure we see here. The powertrain expert mentioned bad materials (i.e. improper hardness or surface finish) and insufficient lubrication, but the third area is the one I find the most interesting: Excessive Clearance. Here's what he had to say about that:

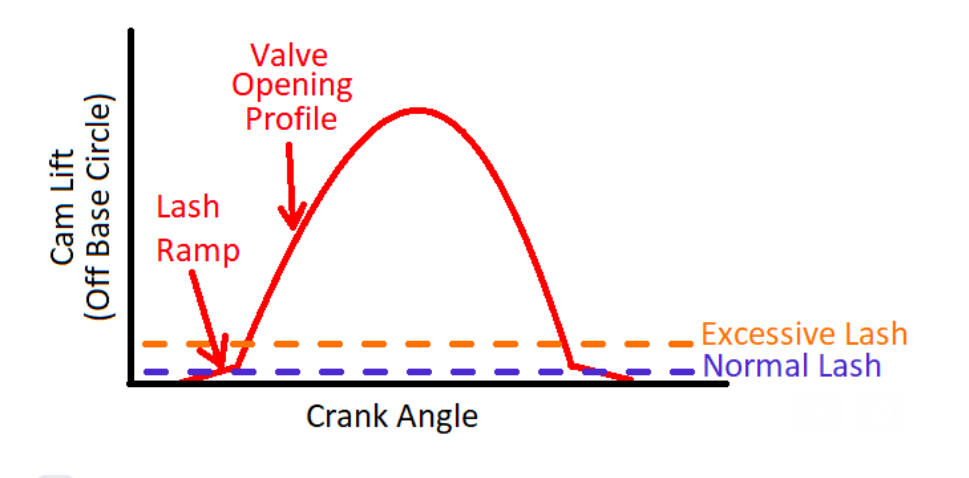

Excessive Clearance: The amount of free clearance in the valvetrain is critical to its longevity, especially when heat cycling. The Hemi 5.7, like just about all modern engines, uses hydraulic lash adjusters (HLA) to keep the proper clearance despite minor wear on the cam shaft, rollers, rockers, valve stem top etc. Miata.net has a good explanation of how they work. My guess is that either debris from assembly or debris in the oil (coked oil, break-in debris, sand from the block or head casting etc) starts blocking one of the places where oil is supposed to feed into or out of the HLA, or stuck in the one-way valve causing leakage. The one-way valve could also be failing for other reasons, but the end result is the same. This causes the HLA to not pump up far enough, increasing valvetrain lash which results in the ticking noise and a much more sudden, forceful impact of the roller onto the cam lobe as it starts to open (or of the back of the HLA onto the push rod, or push rod onto the rocker, etc... doesn't matter much where the lash manifests itself really, the impact is felt through the whole linkage). The much higher force is what causes the oil film to break down, the bearings within the roller to fail and the roller to start eating away at the cam along the opening ramp up to max lift where forces from valvetrain inertia and spring force are greatest. Once this starts, it gets worse pretty quickly since each of these failure modes results in more lash, a more forceful impact, and even more damage until you see the carnage in that video.

The engineer even drew me a little graph, and described how the shape of the camshaft lobe is meant to reduce harsh impacts between the lifter and cam, though the special geometry is not enough to accommodate a failed lifter.

Cam profiles are designed with a very slight ramp at the beginning to gently take up any lash in the system without harsh mechanical jerk, followed by a steep slope meant to quickly force the valve open once all the lash is taken out. The problem is that when there is additional lash in the valvetrain due to one of the HLA failures above, then all this lash exceeds the gentle ramp, and the cam roller is on the steep slope trying to quickly open the valve before the lash is taken out. This results in a a much more abrupt impact when the lash is taken out, much higher point loads on the cam, roller, and other parts, much accelerated wear on those parts, a ticking of the valvetrain, and shorter valve durations. Left unattended long enough, you get the results in that video with large amounts of cam and roller damage, valves that barely open (which will probably cause all sorts of misfires, check engine lights etc), and very audible valvetrain ticking.

Dr. Andy Randolph, technical director at ECR Engines—a NASCAR engine developer based out of Welcome, North Carolina whose lab does lots of failure analyses—gave me his thoughts, too, positing that perhaps there was an issue with oil viscosity. The result would yield the excessive lash that the above R&D engineer told me about:

First, these lifters control lash hydraulically and are designed for 5W20 oil. If the owner uses a heavier oil (for instance a 10W30), this could impede the hydraulic action of the lifters and increase lash between the roller and cam lobe under some operating conditions. This increase in lash will generate impact loading when the lifter contacts the lobe and lead to premature failure of the needle bearings along with the ticking noise that some of the owners report.

Second, the needle bearings are fed oil continuously through the body of the lifter. Once again, if the owner uses a heavier oil then flow to the bearing will be reduced and failure could happen prematurely.

He then discussed the possibility of poor parts quality:

Finally, it is quite possible that the needle bearings have quality problems or are simply inadequate for the loads they experience. We have had failures due to a quality deficiency from our lifter suppler where one needle bearing was missing from the lifter (a normal needle pack is around 15 to 20 needles positioned cylindrically around the roller axle). A missing needle causes the bearings to separate which increases load on the two needles adjacent to the gap. These needles eventually wear and fail, then the needles adjacent to them fail, on and on until the roller element no longer turns. Another common failure occurs when there are slight diametrical differences between the individual needles. Any needle larger than the others will see a higher load and could fail prematurely. Or of course, the needles themselves, or the roller axles, can be too soft or incompatible with each other leading to premature wear.

Failure occurs because lash increases as the needles and/or roller axle wear, increasing impact loading and eventually preventing the roller element from turning. The roller-to-cam interface then becomes a sliding surface rather than a rolling surface, which causes additional lash gain. As lash increases, valve lift and duration in that cylinder decreases, which leads to a loss in performance, a ticking noise from the impact of the lifter to the cam when the lash is taken up, and misfires because the air/fuel mixture in that particular cylinder is awry.

Though not familiar with the Hemi's MDS, Randolph says he doesn't think the cylinder deactivation system is playing a role based on what he's seeing here. In addition, both he and the R&D engineer don't think this failure should lead to a bent pushrod, though Randolph did add that it could happen if "the lash increases sufficiently for the pushrod to be displaced from the cup in either the lifter or the rocker arm. Once displaced, the pushrod could easily become overloaded and bend." That's what I think happened, but that's just a guess.

In any case, it's pretty clear that a fault in the lifter's ability to control lash—possibly caused by debris or improper oil viscosity—could theoretically be the cause of these failures.

I'm hoping some FCA engineer in the know will tell me what's really going on, here, and I'll update this post with that info.

The two video clips above show just how big of a pain in the ass it's going to be to remove the lifters and camshaft. The heads have to come off to get the former and the front timing cover has to come off to swap the latter. It's a huge time commitment, which is why shops are apparently charging upwards of $4 G's to do it.

It looks like I can snag a set of lifters for between $200 and $300 (see above; notice how four are connected by a plastic guide), and a camshaft costs about the same. I'd need a gasket set with head bolts; I can score that for under $150. Add some specialized tools I'd need to to do the job, fluids, and whatever else I'm undoubtedly forgetting right now, and I could see this Get-Car-Project-Money-Quick scheme costing around a grand. That is, if the metal shavings from the worn cam didn't smoke the engine bearings. That'd be a huge bummer.

Yes, in some ways, buying this 2011 Jeep Grand Cherokee is a risk, and would surely eat up lots of my free time. But even if I don't end up making much of a profit to finance my ambitious wrenching endeavor, I have to admit that there's something alluring about the challenge itself, and all the learning I'd do as I tore into the legendary Hemi V8.