Aston Martin Thinks It's Too Good For Stickers

The Aston Martin Valkyrie is a hybrid wonder that will make 1,160 horsepower. It looks like something from another time or planet and sounds incredible. It uses lightweight carbon fiber bodywork and even has optional gold—but no stickers. Aston Martin is apparently too good for stickers.

In a technical briefing presentation that was apparently sent to Valkyrie owners (and forwarded to us by a tipster), Aston Martin devoted 10 slides to the Valkyrie's badge alone. The regular Aston Martin badge is apparently "too heavy" for the car. And a sticker is out of the question because it's not "befitting for a quality and cutting-edge nature." Pardon me for a second here while I roll my eyes so hard I might actually injure myself.

So what's Aston Martin's solution? Little, tiny, itty-bitty slivers of microns-thick stainless steel. Here, I'll let the company explain:

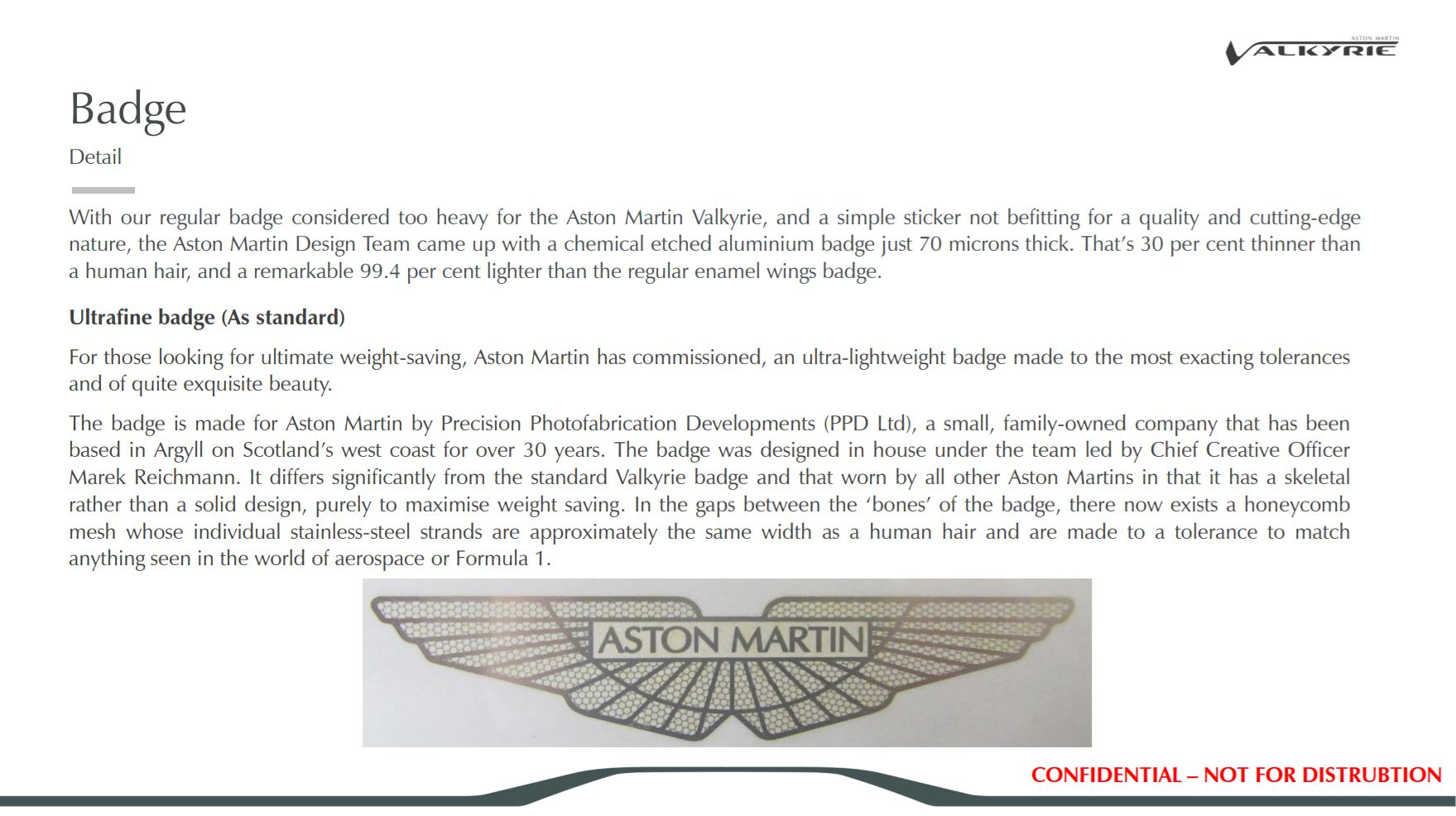

Ultrafine badge (As standard)

For those looking for ultimate weight-saving, Aston Martin has commissioned, an ultra-lightweight badge made to the most exacting tolerances and of quite exquisite beauty. The badge is made for Aston Martin by Precision Photofabrication Developments (PPD Ltd)... It differs significantly from the standard Valkyrie badge and that worn by all other Aston Martins in that it has a skeletal rather than a solid design, purely to maximise weight saving. In the gaps between the 'bones' of the badge, there now exists a honeycomb mesh whose individual stainless-steel strands are approximately the same width as a human hair and are made to a tolerance to match anything seen in the world of aerospace or Formula 1.

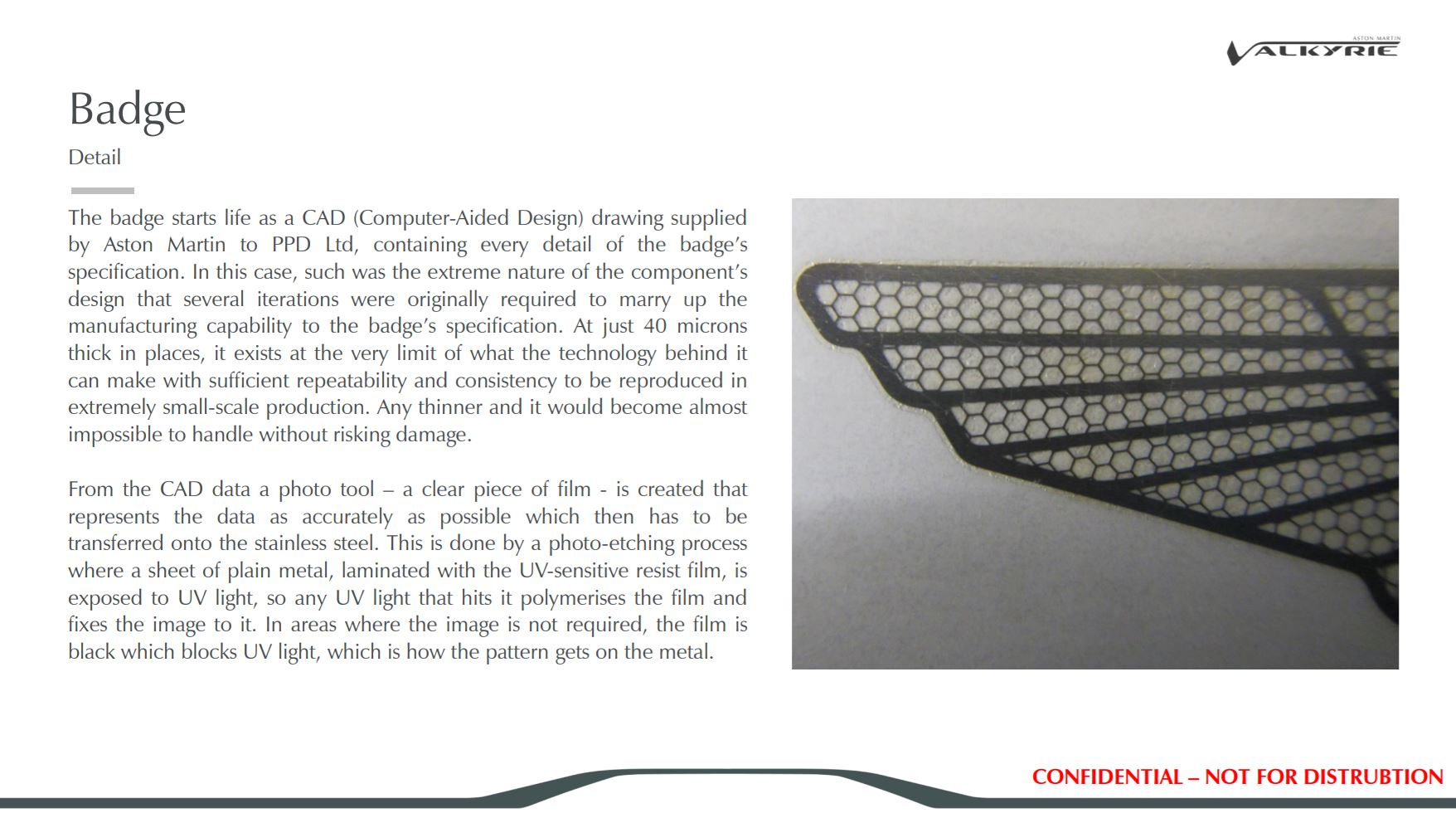

The badge starts life as a CAD (Computer-Aided Design) drawing... At just 40 microns thick in places, it exists at the very limit of what the technology behind it can make with sufficient repeatability and consistency to be reproduced in extremely small-scale production. Any thinner and it would become almost impossible to handle without risking damage. From the CAD data a photo tool – a clear piece of film – is created that represents the data as accurately as possible which then has to be transferred onto the stainless steel. This is done by a photo-etching process where a sheet of plain metal, laminated with the UV-sensitive resist film, is exposed to UV light, so any UV light that hits it polymerises the film and fixes the image to it. In areas where the image is not required, the film is black which blocks UV light, which is how the pattern gets on the metal.

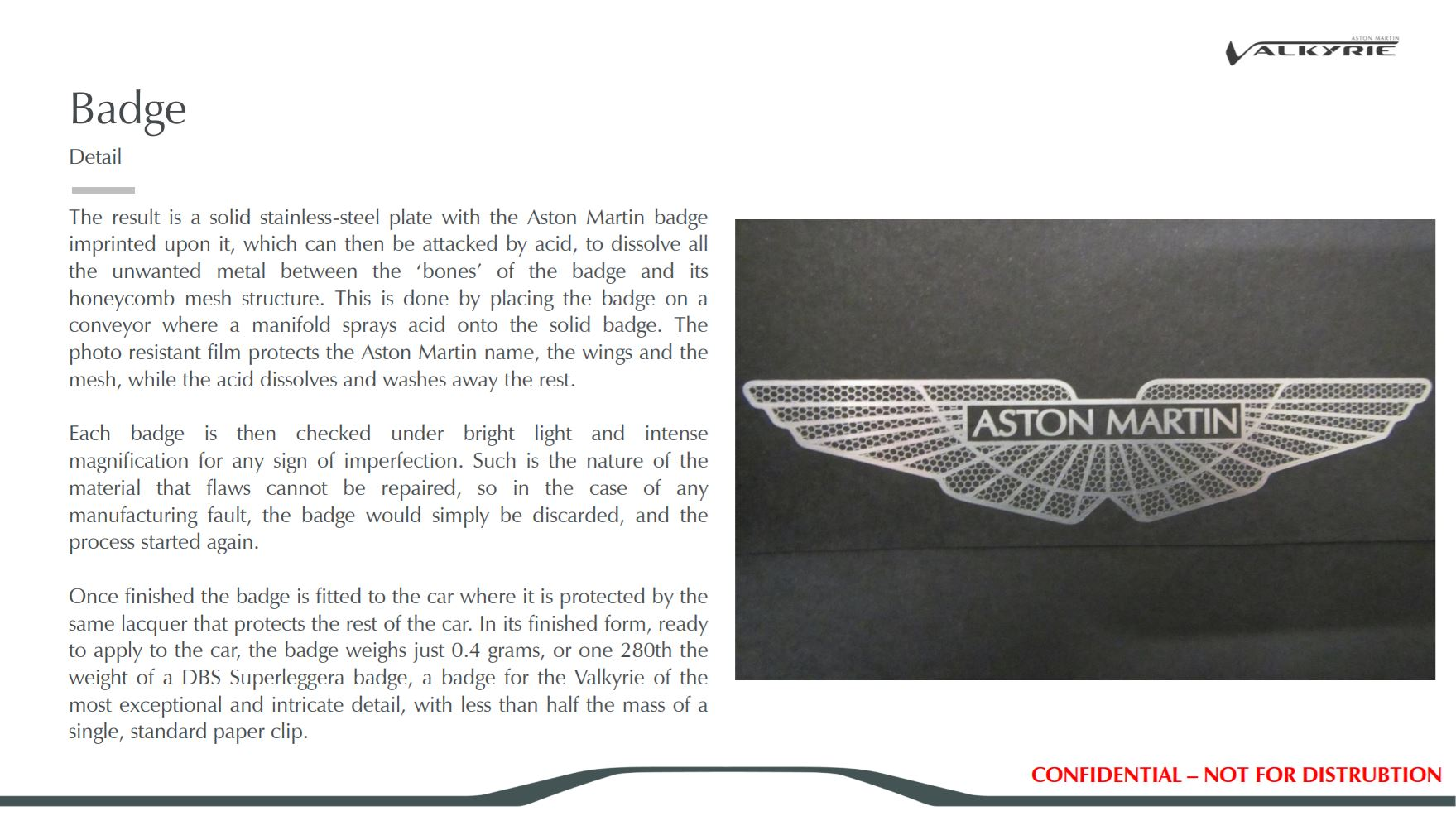

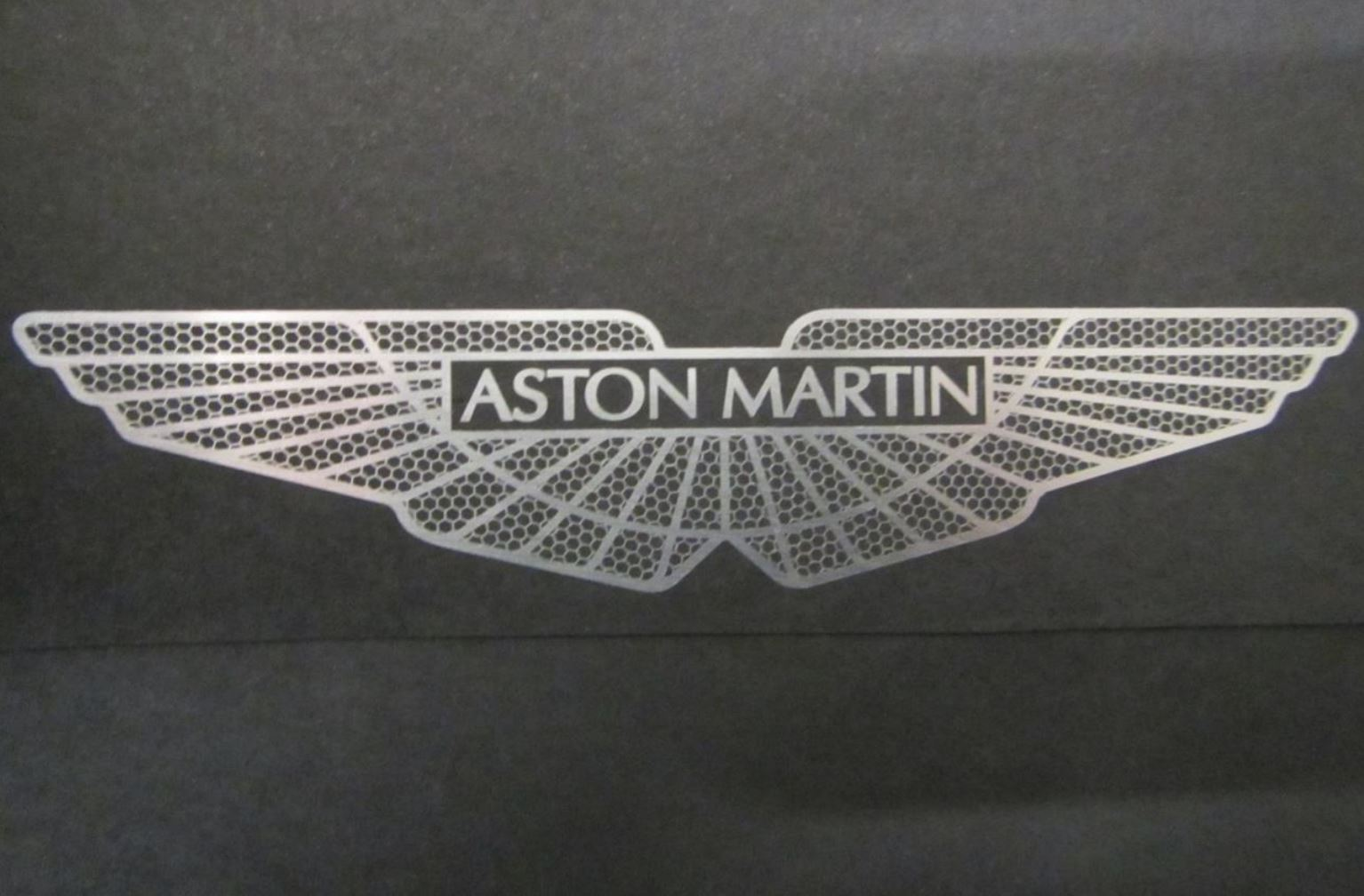

The result is a solid stainless-steel plate with the Aston Martin badge imprinted upon it, which can then be attacked by acid, to dissolve all the unwanted metal between the 'bones' of the badge and its honeycomb mesh structure... Each badge is then checked under bright light and intense magnification for any sign of imperfection. Such is the nature of the material that flaws cannot be repaired, so in the case of any manufacturing fault, the badge would simply be discarded, and the process started again. Once finished the badge is fitted to the car where it is protected by the same lacquer that protects the rest of the car. In its finished form, ready to apply to the car, the badge weighs just 0.4 grams, or one 280th the weight of a DBS Superleggera badge, a badge for the Valkyrie of the most exceptional and intricate detail, with less than half the mass of a single, standard paper clip.

This is that badge. Careful, if you look at it too hard, it might snap.

Oh, but if sir or madame found stainless steel far too lowly and plebeian? There is a titanium option as well.

Laser-etched from solid titanium, the laser slices away from a titanium plate until the badge begins to take form. "A single titanium badge for the Valkyrie requires the undivided attention of the five-axis laser for approximately 12 hours," Aston Martin writes. This is very impressive, as I have an attention span of only about 24 seconds.

And then, "it must be thoroughly sandblasted, using the same machines used by fine watchmakers and jewellers, which fires glass beads just 20 microns across at the badge to remove any discolouring or oxidisation that may be left over from the manufacturing process."

All that effort. All that technology. All that science. All that precision. All to save the most microscopic of ounces, which will all be for naught as soon as the driver gets into the car because their left shoelace is marginally thicker than their right. Or if they ate too much at dinner.

This is all for bragging, of course. No Valkyrie owner is going to want to talk about how their car has a sticker. What is this, a lowly Porsche GT2 RS, for fuck's sake?

You can see the relevant portions of the presentation screenshotted below.