A Short, Positive Video About Tesla's Berlin Factory Ignores Something Important

What Tesla is doing with castings is impressive, but is it good for the company or you?

A recent and oddly reverent video from Bloomberg about Tesla's use of a massive aluminum casting machine to make large, monolithic Model Y chassis components is a good reminder that despite what the angry messages I get on social media tell me, not all Tesla press is negative. Sometimes, it's extraordinarily positive even if that means not addressing some significant issues that affect not just Tesla but the overall car industry. Let's take a look at this.

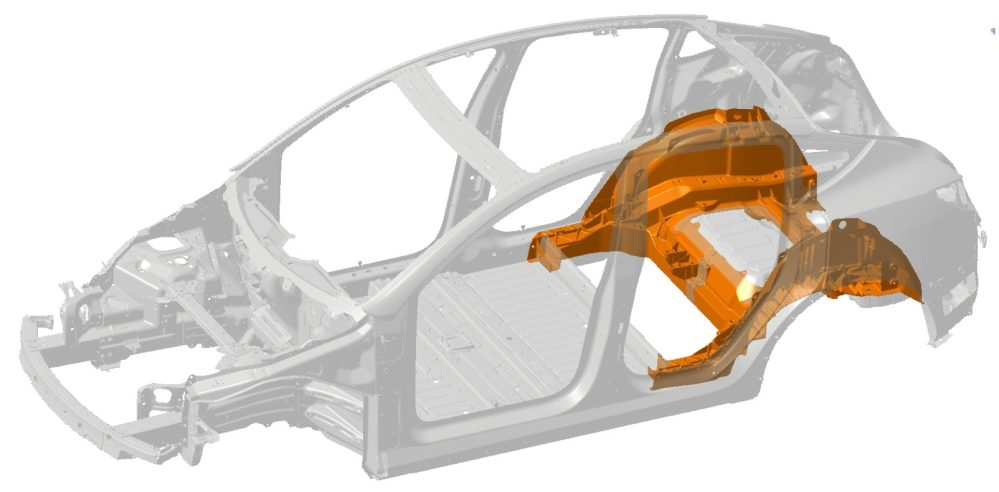

The video, which was released just a few days ago, references something that's been known for over a year: Tesla's new factories will be using massive aluminum casting machines to make major chassis components of the Model Y in their new factories in Germany, Texas, and China.

If you haven't seen the video, here, you can watch my copy:

Elon Musk believes he can radically change how cars are built with Tesla's Giga Press. @nicola_news explains https://t.co/EhTrJyNUsa pic.twitter.com/v36n0SAfsy

— Bloomberg Originals (@bbgoriginals) November 17, 2021

There are a number of interesting things about this video. The whole tone of it suggests that Tesla and Elon Musk are upstart innovators who have developed some revolutionary production methods to attempt to take on and beat the established German auto industry.

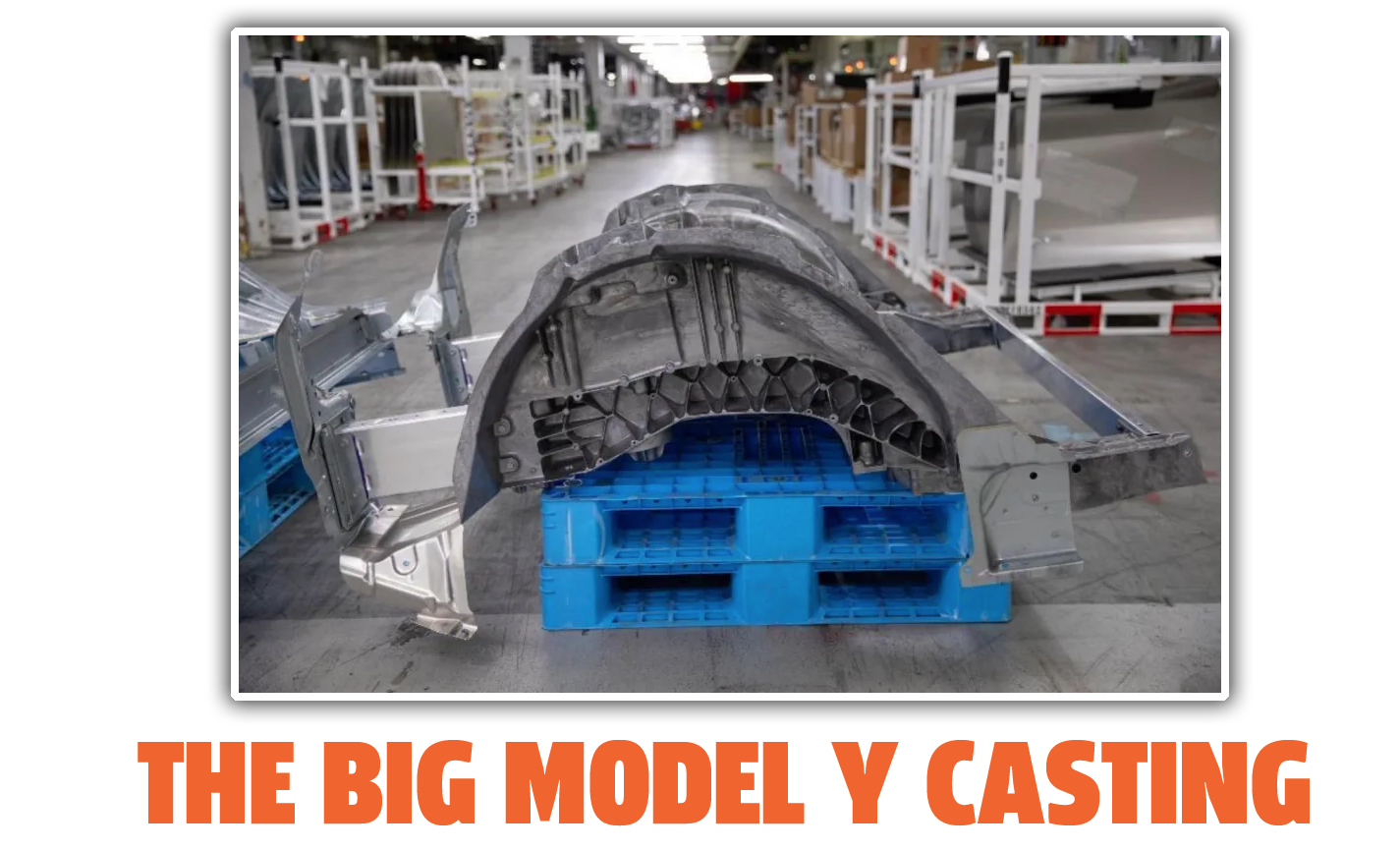

The key to this plan is the Giga Press, which, based on the "giga" name that Tesla has used extensively in its formal and informal branding (think Gigafactory) seems like a Tesla-created innovation. It's not.

The massive press is a commercially available unit available from the Italian company Idra, which will sell you, yes you, an OL 5500/6200 CS Giga Press if you have the money and enough room in your garage.

Idra has had these colossal presses for sale since 2018, but Tesla does deserve credit for being the first automaker to use the press to make such massive castings.

Plus, Tesla did come up with a unique aluminum alloy for its castings, and that's absolutely significant. This achievement isn't exclusively Tesla's — other automakers could buy that same equipment from Idra if they choose. But Tesla has done a lot of important work here, and the casting method definitely simplifies Model Y production considerably.

Now, here's the part that I don't feel videos like this one are addressing enough: do we—and by we I mean the only people I give a shit about in this equation, the car-buying and -using public—actually want cars built this way?

I absolutely get that this production method saves a ton of labor and is cheaper for the automakers to produce. That's a big deal if it keeps costs of new cars down, but the past few centuries of experience with how the world works by no means suggest that's what will happen.

What's more likely is carmakers like Tesla will be able to make more profit per car since they can build them cheaper and more quickly.

That's not a bad thing, but, again, I don't care if every automaker CEO has to eat dog food to keep costs down. What I care about is how these cars will be for regular people to live with, and my concern is that they're going to be unforgiving and unrepairable if they take damage.

Is this something anyone has actually been asking for in new EVs? Sure, a more efficient way to build cars is great. But when you actually have the car, it's yours. You paid for it. It's your responsibility. Are you going to be driving around thinking how cool it is that the company could build the car so easily, and now you have a huge, unrepairable component hanging out four feet behind you as you drive? Are you into that?

A huge cast element is great structurally and to build, but in a wreck, is extremely difficult and expensive to repair. I'm not just pulling this ex recto — even well-known automotive teardown expert and recent Tesla-fan Sandy Munro suggested the same thing in his assessment of this new approach.

As Munro explained to the SAE,

"Castings don't repair very well. If an impact was severe enough, the car's a write-off."

I think this is important because this sort of large-scale casting, along with the use of highly integrated structural battery packs, something also referenced in that video, combine to make modern EVs machines that are very hard to repair and don't age well, a combination that leads to disposability.

We've discussed this topic before here, and we've seen examples of the problem from other automakers, like Ford, whose extensive use of aluminum for F-150 bodies saves weight but leads to massive repair costs and complexities.

Aluminum body repair is getting easier and cheaper over time, but those aren't fundamental structural components like these cast aluminum frame components or structural battery packs.

There's certainly a lot of things to be impressed about by what's shown in that video, and I suspect that what Tesla is attempting now will likely soon spread to other automakers.

But I'm not so sure I want to see any more videos cheerleading these sorts of production advances that appear to benefit the carmakers exclusively. I don't want a world of disposable cars filled with monolithic components that can't be repaired. I don't want a used car market where everything you can buy is a ticking time bomb waiting for that one massive component to fail, rendering the car worthless.

We don't have to accept a future like this. I used to own a Volvo P1800S, and it had a beautiful body with no body panel seams because aside from door and hood and trunk, it was one piece. It was lovely, but even a minor fender-bender would mean absurd repair bills. That made it something of an albatross pendant.

When we see "innovations" in the industry reported on, from Tesla or anyone else, it's time to stop reflexively championing the technology and take a moment to really think about how these innovations will affect the products we'll be buying and how we'll have to live with them.

These aren't things that come up when we look at new cars, necessarily. They're not sexy issues to talk about. They're the grim, dirty reality of how cars get used in our lives, and that needs to be part of the equation moving ahead.

So, sure, way to go on those big cast parts, Tesla. Very cool. Also, no thanks.