Why Do Some High Performance Cars Need Forged Pistons?

Many performance cars, including the supercharged Chevrolet Corvette Z06 and most Ferrari GT models, rely on forged pistons — instead of cast-aluminum pistons — for their additional strength. Forged piston technology isn't new, as automakers have used them in performance cars for decades. It's one of the features that sets the 455 cubic-inch Pontiac V8 apart from Oldsmobile and Buick versions. Ford's Megazilla 2.0 crate engine has the same distinction compared to its 7.3-liter Godzilla stablemate. While Ford's 430-horsepower Godzilla engine is a bona fide workhorse, the Megazilla generates 615 hp, an increase supported by upgrades like Mahle forged pistons.

Gearheads and engine spec nerds alike have probably noticed a correlation between performance car engines and the use of forged internal components, including crankshafts, connecting rods, and pistons. But what makes forged pistons the superior option for those? In 1970, Hot Rod Magazine rounded up representatives from four forged piston manufacturers to find out, by asking:

"Exactly what advantages do forged pistons offer, and what are the best methods and materials used in their manufacture?"

Many of those manufacturers agreed that some high performance cars need forged pistons because the process makes pistons that are more "ductile." In other words, the pistons are able to take more abuse without cracking.

Forged vs. other types of pistons?

There are three types of aluminum pistons used by today's automakers. They are defined either by their production method — cast or forged — or the specialized hypereutectic aluminum alloy used to make them. All hypereutectic pistons are made by casting, though not all cast pistons are hypereutectic.

Casting involves pouring liquid aluminum alloy into a mold where it solidifies into a form that's closer to its final dimensions than forging. Automakers use standard cast aluminum pistons to keep costs down thanks to their simpler manufacturing processes and less expensive alloys. On the other hand, these cheaper materials highlight the weaknesses inherent in cast pistons, especially when applying power adders such as forced induction or nitrous oxide.

Hypereutectic pistons are cast from aluminum alloy containing higher amounts of silicone than standard pistons, allowing them to withstand greater stress. Some crate engines with serious horsepower even use them. Still, regular and hypereutectic cast pistons are both prone to breaking under pressure. Neither one has the strength or durability of forged pistons.

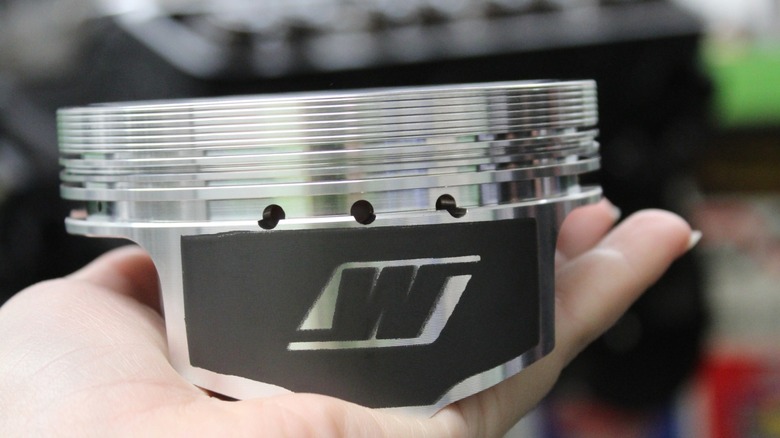

Forged pistons come from a process of heating and pressing the aluminum alloy into cylindrical blocks. Forging forces the alignment of molecules within the aluminum, increasing the finished piston's ductility and toughness. In cast pistons, this alignment is less consistent, often resulting in weak spots. The downsides with forged pistons are time and cost, as forging requires more machining and more specialized equipment than casting.