5 Philosophies Of The Toyota Way That Are Evident In The Brand Today

Let's be honest, 99% of corporate philosophies are just motivational poster trash. Probably cooked up by whichever consulting firm they hired that year. They're meaningless buzzwords like "The 4 Disciplines of Execution" or "Synergy" — whatever that all means.

On a recent long flight, I picked up a book that has been on my shelf for a while now. But finally, "The Toyota Way" got its time under the harsh reading light of a 737. This book spells out the philosophies and ethos of Toyota. It's tangible to how Toyota runs the business today, and can be seen in how the company maintains success or even why its deepest failures became hard-taught lessons. It's cultural DNA built from the inside. It's why Toyota builds cars that seem to outlast generations, why it's still getting accused of dragging its feet on EVs, and ironically why it keeps getting tangled up in scandals.

So, for better or worse, here are five parts of that philosophy you can see all over the brand today.

Base your decisions on a long-term philosophy, even at the expense of short-term financial goals

This is a big one. Let's look at the big electric elephant in the room. While others were tripping over themselves in the EV gold rush, promising an electric lineup by last Tuesday, Toyota looked like it was asleep at the wheel. But the reality was that Toyota was simply playing the long game.

Chairman Akio Toyoda has said, per the Wall Street Journal, "There are many ways to climb the mountain that is achieving carbon neutrality." Toyota is so committed to this that it has an internal "1:6:90 rule". This calculates that the battery materials for one long-range EV could instead make six plug-in hybrids or 90 regular hybrids. It's a long-term bet that patience, resource management, and hybrids will win despite the short-term market hype. Recent sales results show the company may have been onto something. Stick to your guns and let the fads pass.

Build a culture of stopping to fix problems, to get quality right the first time

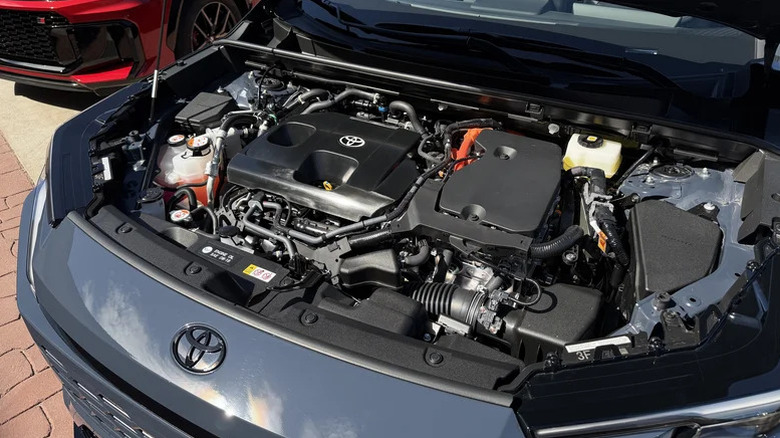

This is a core part of the Toyota production line ethos. Toyota describes this as "automation with a human touch," aka jidoka — similar to Mazda's methodology for laying down that beautiful red paint. Humans are just as important to the process as the robots. Any worker, at any time, can pull the Andon cord to stop the line if they spot something wrong — preventing a defect from moving downstream or, worse, to the customer.

This isn't just a theory. It's the reason Toyota's plants are constantly showered in J.D. Power awards. In 2024, the Toyota plant in Canada won another Gold Quality Award for building the Lexus RX. Oh, and that's the 22nd award for just that one factory. This philosophy builds quality into the production line, rather than inspecting for it at the end.

Kaizen, or learning through continuous improvement

"Kaizen" is a buzzword you've probably seen plastered all over LinkedIn, usually by people who cals themselves "growth hackers" or something dumb like that. Kaizen is legit, though. It's all about learning through continuous improvement.

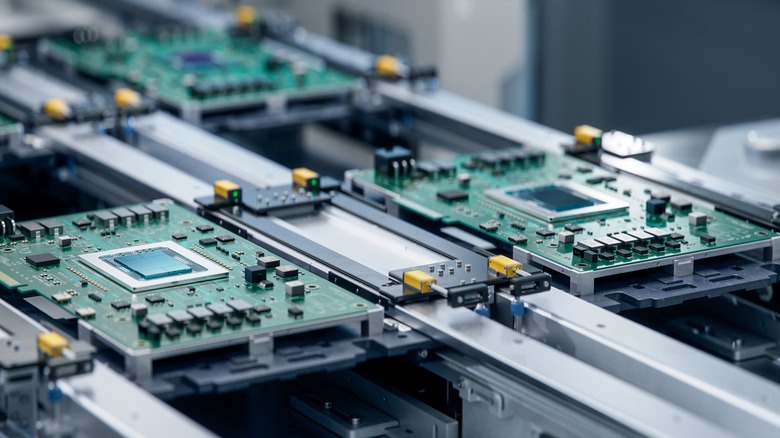

Toyota wasn't affected as heavily as other automakers by the 2020 chip shortages — thanks to a master class in Kaizen. It wasn't a lucky guess, it was a lesson learned from the 2011 Tōhoku disaster. As you could imagine, a large-scale earthquake and a tsunami ruined logistics. That event shattered the company's supply chain, leaving plants dark for months.

Instead of thinking that was a once-in-a-lifetime event, Toyota started building a plan to identify critical parts (yep, including semiconductors) and building a stock buffer as supplies or demands shift. While other automakers got caught with their pants down, Toyota was sitting on a pile of chips, Scrooge McDuck-style. It had already failed and learned from it.

Respect your extended network of partners

This one is genuinely wild in the cutthroat auto industry. Just ask General Motors how effective an unhappy supplier is turning your production line into a ghost town. This is something U.S. automakers seem to back-burner , but in a super-competitive landscape, not treating your suppliers like disposable Pez dispensers is a welcome change of pace.

Toyota's philosophy sees suppliers as long-term partners, not just disposable vendors. Sure, it may challenge them, but it also helps them. Toyota's procurement team will actually send its own engineers to a supplier's factory to run joint workshops. This helps improve their processes and reduce costs, creating a foundation for a sustainable long-term relationship. When Toyota created those buffer stocks we mentioned before, it even shared the financial burden of holding that inventory with its suppliers. Good luck getting your average bean counter to sign off on that.

Go and see for yourself, and relentless reflection

This is where it all comes together. The final pillar is problem solving, and it's built on two key ideas: genchi egnbutsu (go and see for yourself) and hansei (relentless reflection). The most striking recent evidence of this philosophy? The certification scandals.

This has been coming for years — Toyota subsidiaries Hino falsifying emissions since 2003 and Daihatsu faking crash tests for 30 years. How about Toyota faking engine tests? And admitting to its testing violations. That's rough, a complete failure of genchi genbutsu. "Management was not able to fully comprehend and keep track of the details of what was happening on the ground," then-CEO Koji Sato admitted, per AP. They didn't go and see. The results were disastrous.

It's not always about what happens, though, but how you handle it. Instead of sweeping this under the rug, Toyota suspended shipments of all Daihatsu-developed models. It pulled the corporate Andon cord.

The reflection was public. Chairman Akio Toyoda made a deep apology, taking personal responsibility while laying out a plan to fix the situation. This wasn't a press release or a finger-pointing, like other automotive PR disasters. Compare it to the Firestone Tire recall of the early 2000s, when Ford and Firestone blamed each other while Explorers rolled over at an alarming rate. The Toyota Way didn't prevent the failure. But it provided the playbook for recovery.

In the end, that "Toyota Way" book isn't just for corpo-types, though there are some outstanding lessons to be learned. It's the company's source code. It's a system that helps build indestructible Corollas. But when ignored, it creates the very scandals Toyota needs to kaizen its way out of. It's not a perfect philosophy — nothing is. But it's a real one with a solid track record.