What Is Active Fuel Management (AFM) And Why Can It Cause Lifter Noise?

We may receive a commission on purchases made from links.

Imagine you could get all the brawny output of a robust V8 engine in your truck when needed, but also get improved fuel efficiency while casually driving around town. Well, you can with Active Fuel Management (AFM), but some don't think it's worth the negative trade-offs. That may help explain why modern diesel engines still outsell gas in heavy-duty trucks, as they typically offer enhanced torque and efficiency, without cylinder deactivation systems. Starting in the mid-2000's, General Motors began incorporating AFM into select GM engines, including some 5.3-liter, 6.0-liter, and 6.2-liter motors, until it was replaced by Dynamic Fuel Management around 2019.

Essentially, AFM uses specialized lifters on certain cylinders. When the vehicle isn't under load, the engine control module (ECM) can activate the AFM system and send pressurized oil to a set of solenoids, which prevents the lifters from working normally. This allows the AFM system to transform a V8 or a V6 into a four-banger by deactivating cylinders until they're needed again. An AFM system may engage and disengage several times while driving, depending on the situation. The advantage, according to Chevrolet, is that fuel efficiency can bump up as much as 12%. This system sounds great in theory, but, unfortunately, it puts extra stress on the lifters, which can cause a ticking sound — or worse symptoms — in certain situations.

According to the NHTSA, AFM-related problems that can cause ticking and lifter noise include aerated oil, low oil levels, and excess carbon deposits. The recommended course of action for engines with AFM (both in general and to resolve the ticking noise), is to check the oil condition and level frequently to avoid lifter trouble.

Lifter noise could be the least of your problems with AFM

AFM is certainly an intriguing idea, and who doesn't want some extra miles per gallon? The truth is that cylinder deactivation can save you gas, but sometimes it doesn't. Worse still, active fuel management adds complexity, which invites more opportunity for problems. It's not just that the lifters can make ticking sounds — in some cases, misfires, engine damage, and lifter failure can occur as a result of the AFM system. In many cases, the lifters that failed were on the cylinders that could be disabled. Replacing a lifter is not a quick and easy job. Just exposing that part of the engine requires considerable time and labor, which equals a repair bill of potentially thousands of dollars.

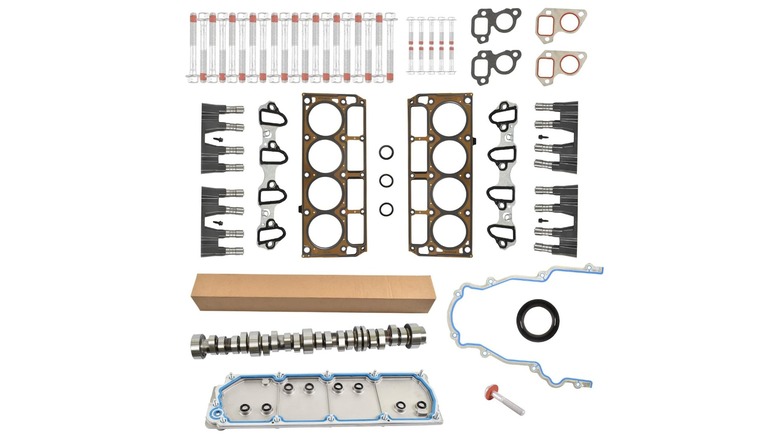

It's for these reasons that some drivers decide to either disable or delete their trucks' AFM systems. Starting at less than $30 for cheap models, an AFM disabler is a device you plug into the vehicle's OBD-II port to deactivate the system at the ECM level. If ticking is persistent, or a lifter has already failed, you may want to consider a delete kit. An AFM delete kit essentially removes all of the parts associated with the cylinder deactivation system and replaces them with standard parts. That said, these kits can cost several hundred dollars, as you'll need to swap out the camshaft, among other internal components.