Coil Packs Explained: How They Work (And Signs They Might Be Failing)

We may receive a commission on purchases made from links.

Is your car misfiring, having trouble starting, or idling rough? Are you wondering if the problem is one of your coil packs? If you're like most drivers, you probably don't think about coil packs unless there is a problem. But your car's engine could not get the power it needs without these impressive little parts.

Did you know that most spark plugs need around 40,000 volts of electricity to make a spark? But if a car battery is typically around 12V, where does all of that power come from? Enter the humble coil pack. These mini-transformers use electromagnetism to amplify the charge from the battery into tens of thousands of volts, enough to get a spark plug sparking.

Ignition coils generally last a long time, but you might have reason to think one or more of them is failing, especially if your car is misfiring or experiencing one of the other power issues we mentioned above. But you'll need to do some troubleshooting to know if the problem is caused by an ignition coil and not something else, like a worn-out spark plug. Fortunately, troubleshooting coil packs isn't that hard. They are easy to get to in most cars, too, which means replacing coil packs can be a simple job. Overall, coil packs cause fewer headaches than a lot of other parts we can think of.

How ignition coils work

How coil packs work, is pretty simple; even a baby could understand it — just kidding. It's actually kind of complex, but still not too hard to grasp. Heck, if we can get it, so can you. Ignition coils are based on something called the Faraday's Law of Induction. This law states that a magnetic field that changes creates an electromotive force, as voltage. The faster the field changes, the more voltage that is created. That's important, because your 12V car battery somehow has to cause each spark plug to receive upwards of 40,000 volts.

To get this done, inside the coil pack is copper wiring wound around an iron core. There are two windings: the wiring in the first winding is wound loosely in comparison to the second, tighter winding. The charge that comes from the battery is sent to the first winding, which creates an electromagnetic field. Switches or distributor points interrupt the charge, causing the magnetic field to collapse or change. This change causes the voltage to surge temporarily, and the field itself collapses onto the second winding. The second winding is much tighter and contains more twists and turns, thus multiplying the voltage enough to cause the spark plug to spark. It's not a lot different from what happens inside an alternator.

You know how the rest works. The spark from the plug ignites the air and gas in the cylinder, creating a small explosion which causes the piston to move. This has to happen hundreds of times a minute, with the pistons firing in the right order, for the engine to run. While there are different types of spark plugs, they all work this way. Tl;dr version – coil packs help make your car go.

Different types of coil packs

Remember distributors? (If so, we tip our glasses of Metamucil to you.) In the old days, cars came with just one ignition coil. This single ignition coil would send a current to the distributor, which would distribute the voltage to each spark plug in the right order.

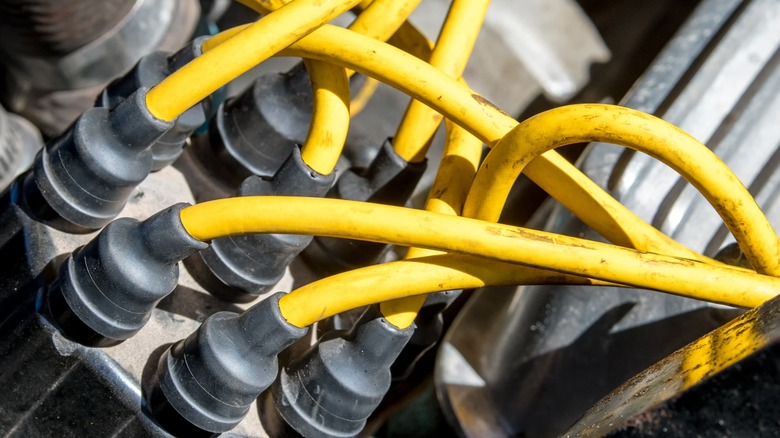

But in the 1970s, manufacturers started making cars without distributors and over the years phased them out entirely. In these newer cars, charge is sent directly to the coil packs, which then charge the spark plugs. At first, the distributor-less ignition systems (DIS) were designed to have multiple coil packs, each of which would charge two spark plugs. Nowadays, most ignition systems are coil-on-plug (COP) systems, which have even more coil packs, one seated right on top of each spark plug. Some systems are a little different and use CNP, or coil-near-plug systems, with the coil packs mounted close to the plug, connected by a short cable.

There are lots of advantages to each spark plug being directly connected to its own, dedicated coil pack. For one thing, there's no need for spark plug wires, which could get damaged and cause a misfire. The multi-coil arrangement also results in cleaner, more fuel-efficient performance. And it makes changing spark plugs a little simpler, in that you don't have to worry about accidentally connecting plugs to the wrong distributor terminal when you re-attach the spark plug wires. That would cause the cylinders to fire out of order, resulting in some serious damage.

Signs your coil packs are failing

If you're worried about how often to change your coil packs, don't be. Most of them are made to last 120,000 to 150,000 miles, depending on the car. But like everything else, they do fail prematurely sometimes. Heat and vibration can cause them to wear out; so can oil leaking in from damaged valve cover gaskets. In other words, you'll only need to replace them if they appear to be failing.

There are several things that could be signs one or more of your coil packs are failing. But none of those things by themselves definitely pinpoint one of your coil packs as the culprit. For example, engine misfiring is a pretty common sign your coils are failing. But there could be a number of causes for that, like spark plugs that should have been changed a while ago. In fact, worn spark plugs themselves can cause a coil pack to fail.

Other signs could be an engine that won't start, rough idling, power loss, engine stalling, gas mileage that's gotten worse, and backfiring. Again, failed coil packs aren't the only possible cause of a non-starting engine or any of those other symptoms, and throwing parts at a problem until it goes away can get expensive. So you'll want to do some more troubleshooting if you notice any of these things.

How to tell for sure that your coil pack is the problem

There are specialty tools you could buy to diagnose the problem yourself, like inductive pickup adapters or the Waekon Coil On Plug Ignition Quick Probe. But each of these tools can cost over $100, which might not be worth it if you're only going to use it once. You're better off using an OBD-II reader or spark tester to diagnose the problem. You can get a low-end OBD-II reader for around $20 or less. And a code reader especially could save you a lot of time and money down the road if you plan on getting under the hood of your car a lot.

If you do use a code reader, the codes you're looking for are P0351-P0358. Each of those codes indicates there's a problem with a coil pack or its surrounding circuitry. The last digit corresponds to the cylinder where the coil pack is situated. In other words, code P0353 would indicate there is a problem with the coil pack on the third cylinder.

Using an inline spark tester is pretty easy, especially if you know which cylinder is misfiring. Just disconnect the coil pack, connect one end of the spark tester to the output on the coil pack and the other end to the spark plug. Have someone else turn on the engine and rev it up and down. If the coil is working, you should see a consistent spark in the tester, including at higher rpm. Another way to tell if your coil pack is the problem is called "swap testing." If you know which cylinder is misfiring, you can swap its coil pack with one from another cylinder. If the other cylinder misfires instead, the coil pack is to blame.

How to swap out a coil pack

You could take your car to a mechanic to have a coil pack replaced. But if you're like us, you might like to get your hands dirty, before taking it to a mechanic. Besides, this job could cost you from around $200 to over $300 at a shop. Doing it yourself could save you over $100, and it's usually an easy DIY job.

The first step, of course, is to make sure the engine is off, and the negative terminal of the battery is disconnected. Technically, there is pretty much no chance of getting shocked by the coil if the engine is off, since it's not charged unless the car is running. But it's better to be safe than sorry. The rest of the steps are specifically for newer cars with the coil-on-plug systems. We've made these instructions pretty broad to apply to as many vehicles as possible. So check with the manufacturer for steps specific to your car.

First, find the coil pack that is failing. Hopefully, it's right on top of the engine and not under the manifold, which would cause you more work. Then, unplug the connector and check it for dirt and corrosion. Unscrew the coil pack from its mount. Rotate the coil pack back and forth a little in case it's corroded to the spark plug. Now, gently pull the coil pack straight up to disconnect it from the plug. Put a little dielectric grease on the plug boot of the new coil pack, push the new pack onto the spark plug, mount it, and plug it in. Coil packs are remarkable little parts that don't get a lot of attention sometimes. But your engine couldn't run without them.