Step Inside A Factory Building 1960s Airliners

Stories about lost parts and corners being cut on the production line might give American aviation a bad rap these days, but it's always fun to look at how far we've come in more than half a century of aerospace research. That's where this vintage footage taken inside the factory that assembled McDonnell Douglas DC-10 aircraft comes in.

Boeing wasn't always the biggest name in American aerospace, and back in the 1960s a company called McDonnell Douglas churned out some pretty iconic civil jets that went into service across the U.S. and around the world. The company's most famous plane was probably the DC-10, a strange machine with a jet engine on each wing and a third mounted to the tail of the aircraft.

In a new video shared by excellent YouTube channel Boeing Classics, workers at the McDonnell Douglas show off what it took to assemble a DC-10 back in the 1960s.

They don't build them like this anymore

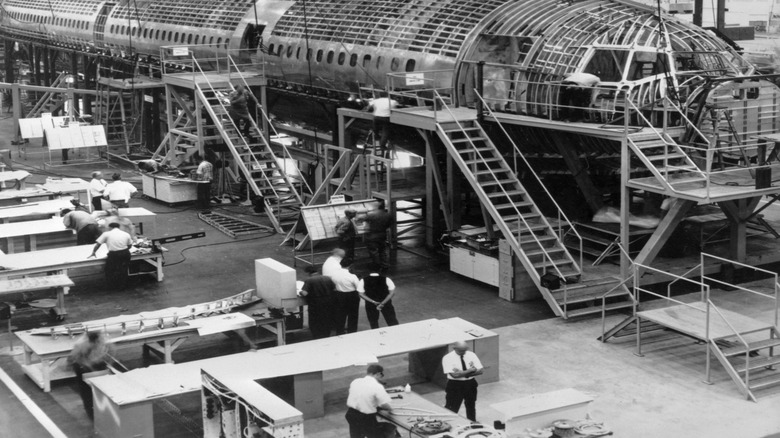

The clip, which you can see for yourself above, shows four DC-10 fuselages lined up inside an enormous factory. In one, a crew is working to pack insulation into the body of the plane, while another sees crews working to seal all the workings of the plane in.

Inside another fuselage, workers are installing all manner of wiring looms and plumbing, while another is being lined with the kind of plastic window surrounds that wouldn't look out of place on a modern commercial jet.

At the opposite side of the plant, tail sections of the 300-passenger aircraft are being assembled and the housing for that third engine on the tail is being fabricated. Another side of the plant is working on nosecones, with windows being fitted to three different cockpits.

Unite the thirds

Once the three sections of the 180-foot long aircraft are fabricated, they are brought together with the 155-foot wings. The components are all carefully hauled into place, before being riveted together at the seams.

When they are connected, work begins on the mechanics of the planes with flaps and ailerons installed on the wings and tails, and equipment is strapped to the nose of the DC-10. At this point, there's a choreographed display as all manner of parts and components are swung into place while ladders are lent up against different surfaces and engineers get to work.

The final piece of the puzzle is the installation of the three engines, which were either General Electric CF6 units or Pratt & Whitney JT9D turbofan engines depending on the variant. The DC-10 was in production for almost 20 years and McDonnell Douglas churned out almost 400 of the aircraft in this manner.

What happened to the DC-10?

While the DC-10 operated commercially from the early 1970s right up to 2014, none of the nine remaining aircraft fly passengers anymore. The majority of these remaining planes work as cargo carriers, and one remaining DC-10 is used as a firefighting aircraft here in North America.

Despite remaining in limited service today, production of the DC-10 ceased in the late 1980s after slowing sales for the commercial jet. It had been plagued with safety issues, crashes and problems with fuel economy, which meant it wasn't a popular jet for many operators.

So sure, maybe footage of the construction of a plane that was caught up in more than 50 incidents that led to the deaths of more than 1,200 people might not be the best way to look back on the golden age of American aviation.